Terahertz radiating material and preparation method and application thereof

A technology of terahertz radiation and raw materials, which is applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of tap water pollution, high cost, and high price, so as to reduce viscosity and surface tension, improve combustion efficiency, and reduce activation Can effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] This embodiment also provides a method for preparing a terahertz radiation material, including:

[0042] S1. Mix 30-85 parts of the above silica powder, 5-30 parts of aluminum oxide powder, 1-20 parts of ferric oxide powder, 1-15 parts of zirconium compound powder, 1-10 parts of potassium oxide powder and rare earth 0.01-0.1 parts of the oxides are mixed to obtain a powder mixture.

[0043] Further, 1-5 parts of radiation material powder and 1-5 parts of activated carbon powder are added to the above powder mixture. And the powder mixture is sieved, and the mesh number of the sieve is 100-200 mesh. The particle size is between 100-200 mesh, which can make the mixing of these several raw materials more uniform, thus providing effective guarantee for the subsequent preparation process.

[0044] S2. Sintering the powder mixture in an oxygen-free state to obtain a sintered body.

[0045] Preferably, the sintering temperature is 500-1800 degrees Celsius, more preferably, ...

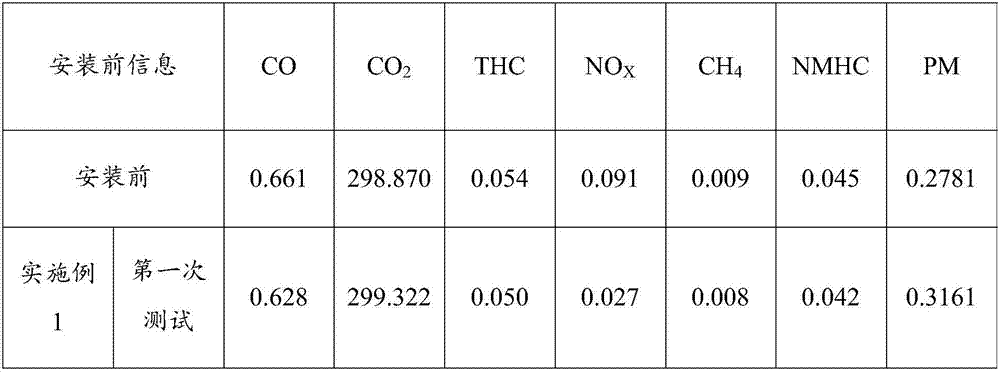

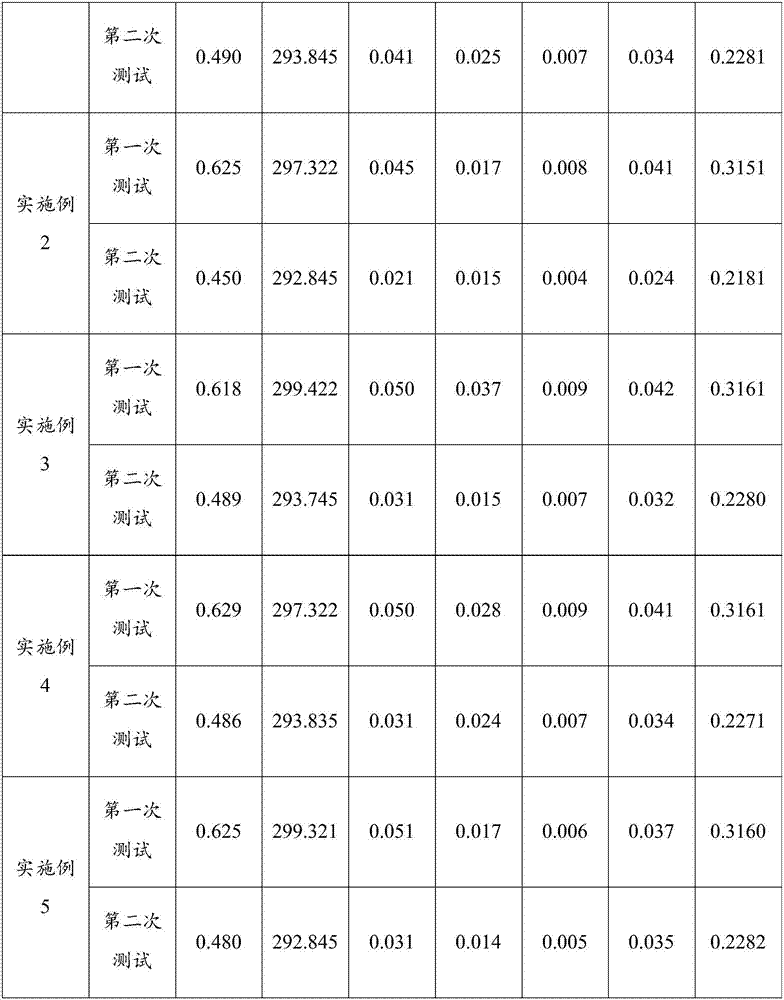

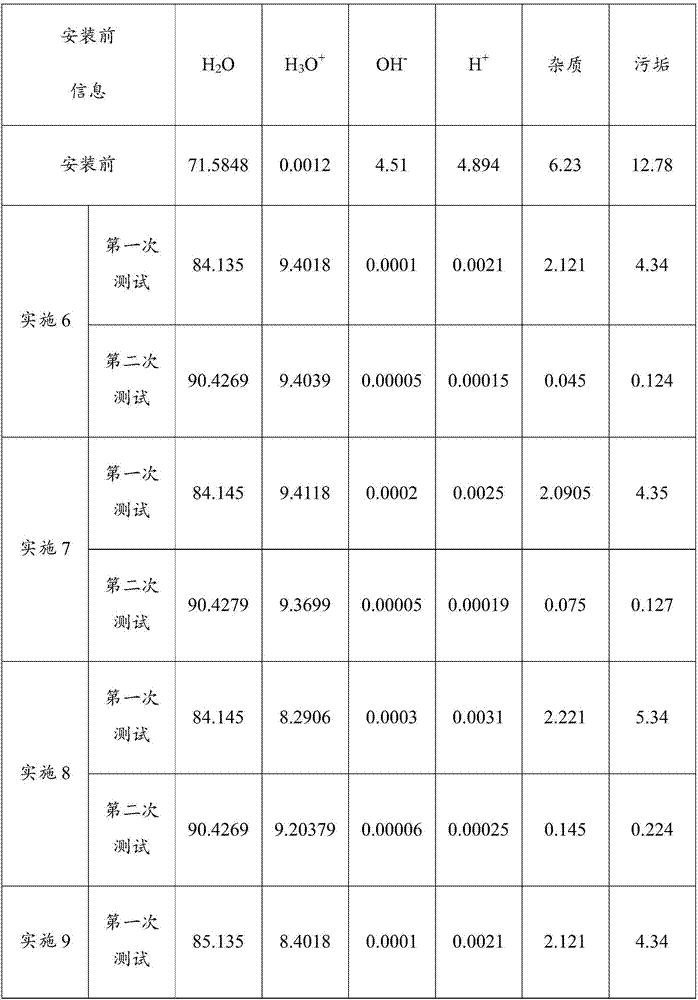

Embodiment 1

[0055] This embodiment provides a terahertz radiation material, and the raw materials of the radiation material mainly include:

[0056] Silica powder 50g, aluminum oxide powder 10g, iron oxide powder 3g, zirconium carbide powder 2g, potassium oxide powder 1g, activated carbon powder 1g, tourmaline 1g, neodymium oxide 0.01g.

[0057] The preparation method of the radiation material is as follows: grinding the above raw materials, passing through a 100-mesh sieve, mixing evenly, and sintering at 500° C. for 10 hours in an oxygen-free state. Prepared terahertz radiation materials.

Embodiment 2

[0059] This embodiment provides a terahertz radiation material, and the raw materials of the radiation material mainly include:

[0060] 80g of silica powder, 20g of aluminum oxide powder, 10g of iron oxide powder, 8g of zirconium dioxide powder, 7g of potassium oxide powder, 5g of tourmaline and 0.1g of ytterbium oxide.

[0061] The preparation method of the radiation material is as follows: grinding the above raw materials, passing through a 200-mesh sieve, mixing evenly, and sintering at 1800° C. for 20 hours in an oxygen-free state. Prepared terahertz radiation materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com