Method for recovering gold, silver, iron and lead from acid calcination slag by magnetization chlorination process

A technology of chlorination and recovery of gold, which is applied in the fields of silver, iron and lead, and recovery of gold, which can solve problems such as high cost, difficulty in recovery, and environmental pollution, and achieve the goal of increasing economic benefits of enterprises, eliminating environmental pollution, and reducing smelting costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for reclaiming gold, silver, iron and lead from acidified roasting slag by magnetization chlorination, comprising step 1 and step 2;

[0019] Said step 1 includes:

[0020] (1) Mix evenly with 18%~50% concentration of sodium chloride and 1~3mm of coal powder and cinder;

[0021] (2), by weight, slag: sodium chloride: coal powder = 1: 0.05~0.5: 0.02~0.2, granulate after stirring and mixing, and its mixing time is 1~3 hours, so that it forms a particle size of 20- 30mm pellets;

[0022] (3) After drying, consolidation and roasting, the roasting temperature is 900-1250°C, and the roasting time is 1-3 hours;

[0023] (4) Collect the roasting flue gas, and spray the flue gas at a temperature of 1000 ° C to 1050 ° C during the roasting process to cool down to the outlet temperature of 20 ° C to 50 ° C, so that the chloride crystals of silver, copper and lead are precipitated, and the output is recovered by filtration Gold, lead chloride, and silver chloride solids...

Embodiment 2

[0030] The method for reclaiming gold, silver, iron and lead from acidified roasting slag by magnetization chlorination method is made up of step 1 and step 2, and described step 1 comprises:

[0031] (1) Mix uniformly with 1.2-2.8mm of coal powder and tailings with 19%-45% concentration of sodium chloride;

[0032] (2), by weight, slag: sodium chloride: coal powder = 1: 0.06~0.49: 0.025~0.19, granulate after stirring and mixing, the mixing time is 1.5~2.5 hours, so that the particle size is 22-28mm pellets;

[0033] (3) After drying, consolidation and roasting, the roasting temperature is 950-1200°C, and the roasting time is 1.2-2.8 hours;

[0034] (4) Collect the roasting flue gas, and spray the flue gas at a temperature of 1000 ° C to 1050 ° C during the roasting process to cool down to the outlet temperature of 20 ° C to 50 ° C, so that the chloride crystals of silver, copper and lead are precipitated, and the output is recovered by filtration Gold, lead chloride, and si...

Embodiment 3

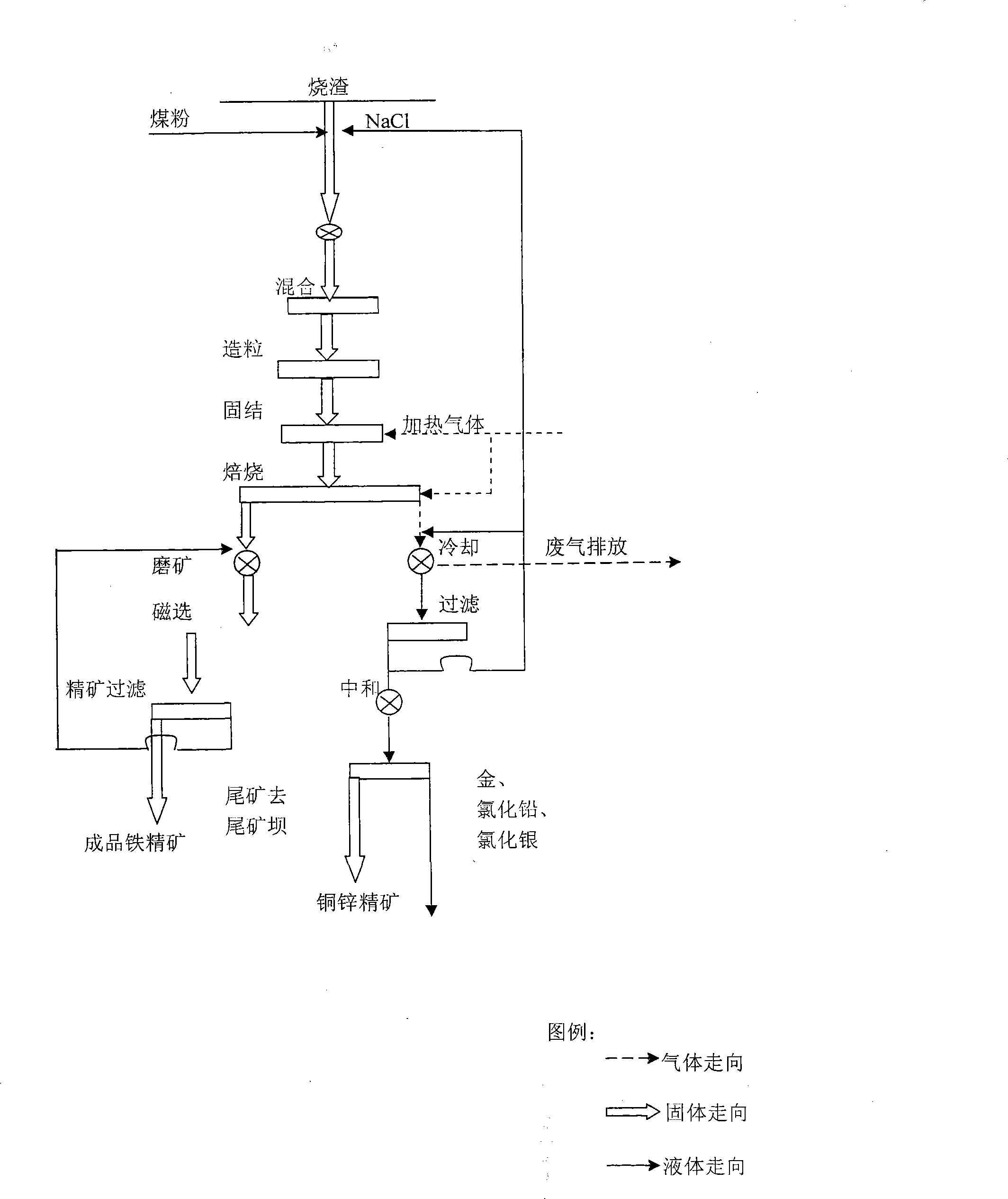

[0038] Referring to Fig. 1, the magnetic chlorination method of solid is mixed with additives of acidified roasted slag, coal powder and liquid, granulated, consolidated, roasted, and the solid part of the roasted product is sent to a ball mill for ball milling. The particle size of -200 mesh should account for 80%, and then the existing magnetic separation process is used for magnetic separation, and the concentrate obtained by magnetic separation is filtered with water to form iron concentrate, and the tailings obtained by magnetic separation are sent to the tailings mine dam. After roasting, the hot gas is mixed with cooling water, and the flue gas with an inlet temperature of 1000-1050°C is cooled to an outlet temperature of 20-50°C by spraying cold water, and part of the exhaust gas is discharged into the atmosphere, and part of the filtered solid is silver copper. Chloride crystallization of lead, while gold is produced in the form of simple substances, the solids produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com