Preparation method of novel wool-like differential fibers

A chemical fiber and wool-like technology, which is applied in the field of preparation of new wool-like differential fibers to achieve excellent wearability and improvement of antigenic fibrosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

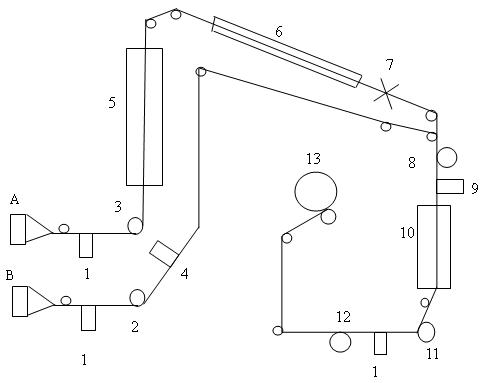

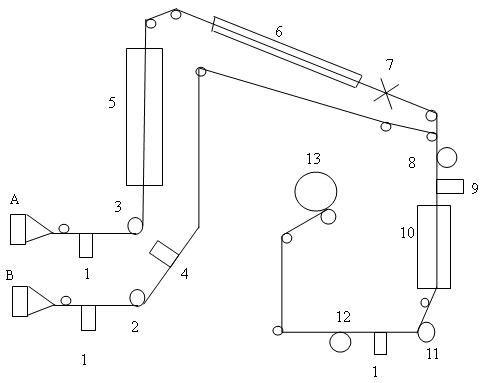

[0016] Example 1: Polytrimethylene terephthalate (PTT) was used as a raw material to produce 140D / 72f pre-oriented yarn (a) with a monofilament fineness of 1.9dpf, a hexalobal cross-section, and an elongation at break of about 85%; Use polyester FDY drawing equipment to produce 100D / 36f, single filament fineness is 2.8dpf, fully drawn high boiling water shrinkage yarn (b), modified with isophthalic acid and isoprene glycol, boiling water shrinkage rate is 40%, cross section Circles and hexagons. Composite is carried out on the Murata false twist texturing machine model 33H, the pre-oriented yarn (a) passes through one roller, one hot box, cooling plate, false twister in turn, and shrinks before the second roller and passes through the zero roller full-drawing high boiling water The filaments (b) are merged, then compounded by the network device, and then sequentially passed through the second heat box, the third roller, the oil tanker, and finally wound into filaments. The pr...

Embodiment 2

[0017] Example 2: Polytrimethylene terephthalate (PTT) was used as a raw material to produce 100D / 72f pre-oriented yarn (a) with a monofilament fineness of 1.4dpf, a hexalobal cross-section, and an elongation at break of about 85%; Use polyester FDY drawing equipment to produce 100D / 36f, single filament fineness is 2.8dpf, fully drawn high boiling water shrinkage yarn (b), modified with isophthalic acid and isoprene glycol, boiling water shrinkage rate is 30%, cross section Circles and quadrilaterals. Composite is carried out on the Murata false twist texturing machine model 33H, the pre-oriented yarn (a) passes through one roller, one hot box, cooling plate, false twister in turn, and shrinks before the second roller and passes through the zero roller full-drawing high boiling water The filaments (b) are merged, then compounded by the network device, and then sequentially passed through the second heat box, the third roller, the oil tanker, and finally wound into filaments. ...

Embodiment 3

[0018] Example 3: Polytrimethylene terephthalate (PTT) was used as a raw material to produce 140D / 72f pre-oriented yarn (a) with a monofilament fineness of 1.9dpf, a quatrefoil-shaped cross section, and an elongation at break of about 85%; Using polyester FDY drawing equipment to produce 75D / 24f, single-filament fineness of 3.1dpf, full-drawing high-boiling water shrinkage yarn (b), modified with isophthalic acid and isoprene glycol, boiling water shrinkage rate of 45%, cross-section circles and triangles. Composite is carried out on the Murata false twist texturing machine model 33H, the pre-oriented yarn (a) passes through the shredder, the first roller, the first heat box, the cooling plate, the false twister in sequence, before the second roller and the full drawing of the zero roller Stretching and boiling water shrinkage yarns (b) converge, and then compounded by the network device, and then passed through the second heat box, the third roller, the oil tanker, and finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com