Method for preparing rock wool panel by melting solid waste

A technology of solid waste and rock wool board, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increased operating costs, low rock wool output, high energy consumption, etc., and achieve good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

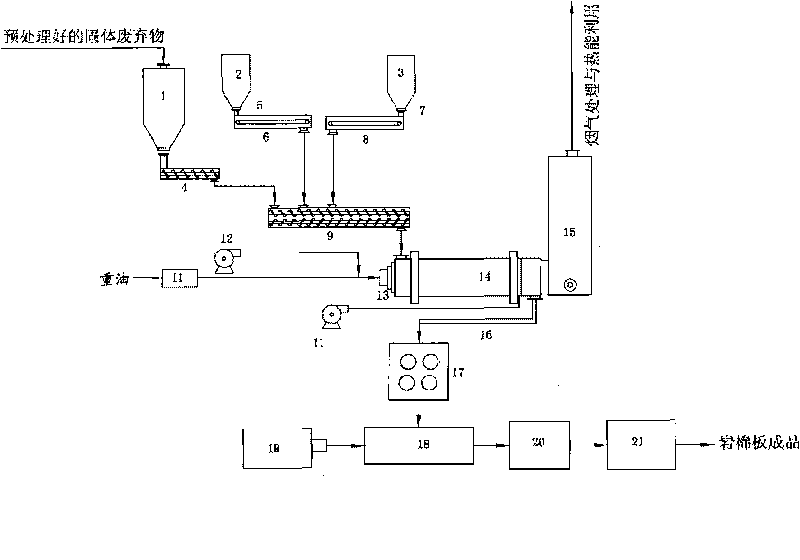

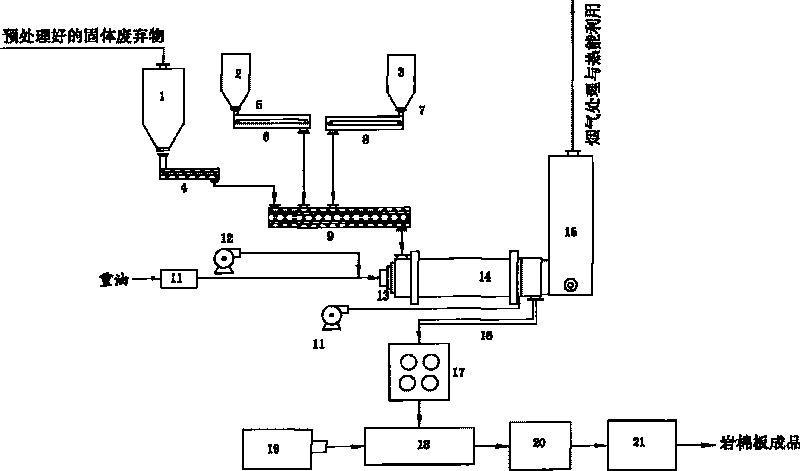

Method used

Image

Examples

Embodiment 1

[0036] The domestic garbage in a garbage disposal site is measured to have a moisture content of 35% after pretreatment such as sorting, crushing, and drying. Take 1000Kg of domestic garbage with a moisture content of 35%, and add 80Kg of additive 1 # and 95Kg additive 2 # , fully mixed evenly, and then adopt the rock wool production process of the present invention to produce rock wool boards. The temperature of the rotary kiln is controlled at 1500°C, the acidity coefficient of the melt is about 1.45, and the fluctuation range of the chemical composition is small. The produced rock wool board is found to meet the strength requirements of ordinary rock wool boards such as compressive strength and tensile strength through the test of mechanical properties; the rock wool board is broken into debris with a particle size of less than 5mm, and the hazardous waste leaching toxicity is identified. It is found that its heavy metal content is also far below the limit value of "Leach...

Embodiment 2

[0038] After the sludge of a municipal sewage treatment plant is dried and pretreated, its moisture content is measured to be 50%, and the sludge with a moisture content of 50% is 1000Kg, and 60Kg of additives are added 1 # and 65Kg additive 2 # , fully mixed evenly, and then adopt the rock wool production process of the present invention to produce rock wool boards. The temperature of the rotary kiln is controlled at 1450°C, the acidity coefficient of the melt is about 1.6, and the fluctuation range of the chemical composition is small. The produced rock wool board is found to meet the strength requirements of ordinary rock wool boards such as compression and tensile strength through the test of mechanical properties. The rock wool board was crushed into slag with a particle size of less than 5mm, and the heavy metal content was found to be far lower than the limit value of "Leach Toxicity Identification of Hazardous Waste Identification Standards" (GB 5085.3-1996) after the...

Embodiment 3

[0040] The decontamination sludge of a certain river course removes coarse stones, etc. After drying and pretreatment, its moisture content is measured to be 45%. Take 1000Kg of silt with a moisture content of 45%, and add 4.5Kg of additive 1 # and 4.6Kg Additive 2 # , fully mixed evenly, and then adopt the rock wool production process of the present invention to produce rock wool boards. The temperature of the rotary kiln is controlled at 1530°C, the acidity coefficient of the melt is about 1.7 and the fluctuation range of the chemical composition is small. The produced rock wool board is found to meet the strength requirements of ordinary rock wool boards such as compression and tensile strength through the test of mechanical properties. The rock wool board was crushed into slag with a particle size of less than 5mm, and the heavy metal content was found to be far lower than the limit value of "Leach Toxicity Identification of Hazardous Waste Identification Standards" (GB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com