Direct linkage type four-roller centrifuging machine for producing rock wool

A four-roll centrifuge, direct-connected technology, used in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of inconvenient hoisting and maintenance, uneven force on the centrifugal shaft, vibration of the centrifugal shaft, etc., and achieves easy installation and maintenance. The effect of increasing the qualified rate of fiber forming and reducing the size of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

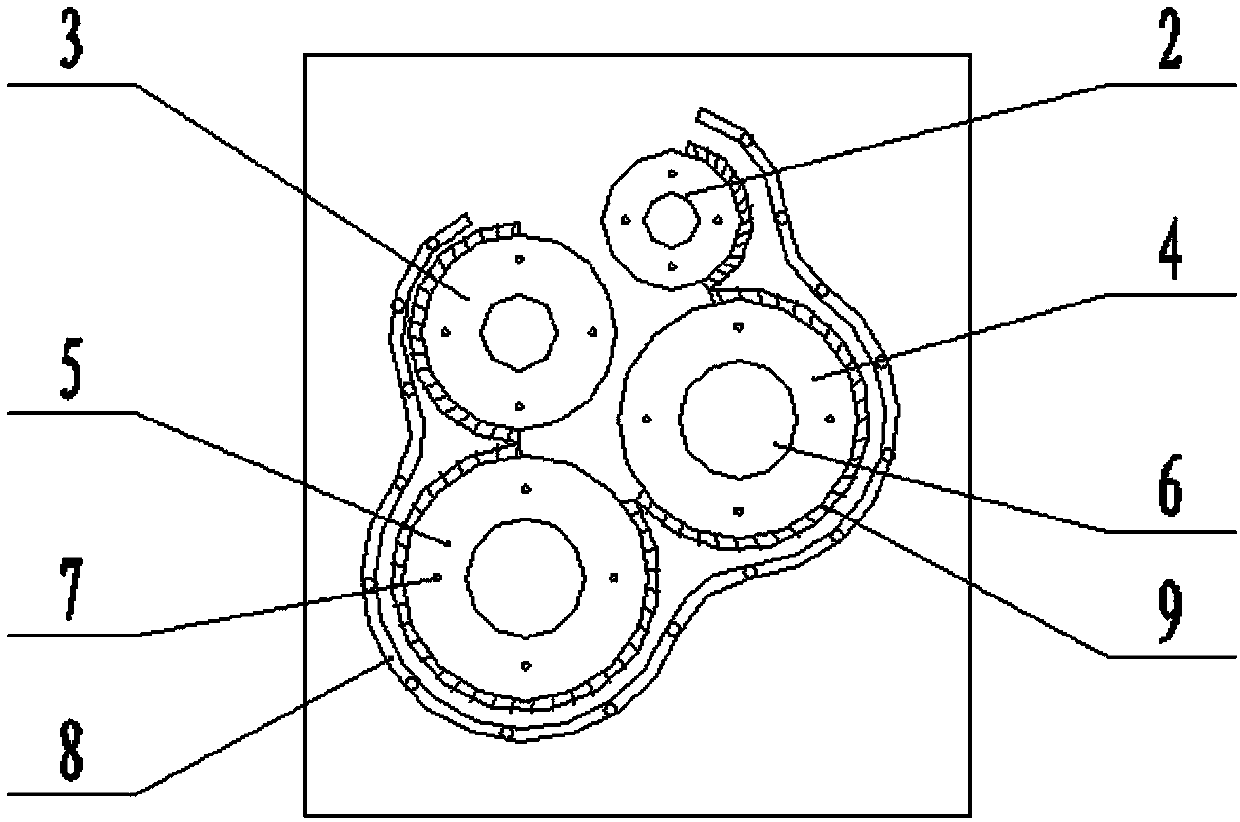

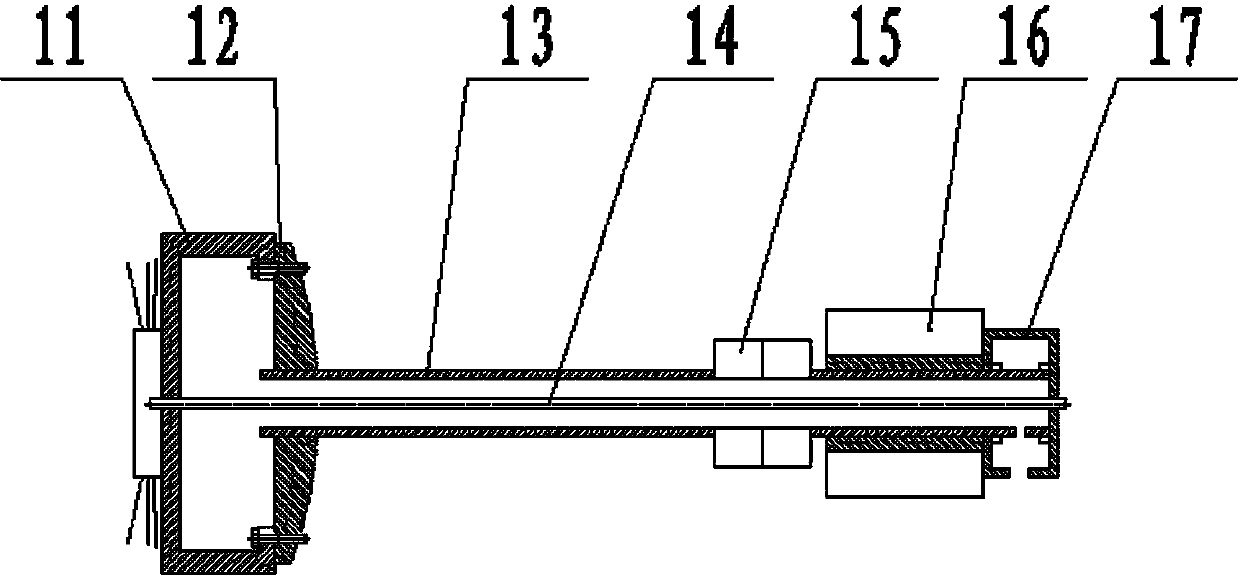

[0008] The present invention will be further described now in conjunction with accompanying drawing, figure 1 It is an embodiment of the present invention, including four roller bodies, motor 16 and glue spraying device, and the four roller bodies are respectively: No. 1 centrifugal roller 2, No. 2 centrifugal roller 3, No. 3 centrifugal roller 4 and No. 4 centrifugal roller Roller 5, each roller body comprises roller head 11, rotating shaft 13, and evaporation mouth, and usually roller head 11 is the cavity of cylindrical shape, and roller head 11 is connected on the front end of rotating shaft 13 by flange 12, and rotating shaft 13 rear ends It is connected with the motor 16 through the coupling 15 . Glue spraying device comprises cooling water pipe and glue spraying pipe 14 etc., and rotating shaft 13 is a hollow shaft, is placed on the outside of cooling water pipe, and cooling water pipe is sleeved on the outside of glue spraying pipe 14, and rotating shaft 13, cooling wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com