Flexible circuit board and manufacturing method therefor

A technology of flexible circuit boards and manufacturing methods, which is applied to printed circuits, printed circuits, printed circuits connected with non-printed electrical components, etc., can solve the problems of multiple signal reflections, signal transmission energy loss, etc., and reduce signal transmission. Loss, avoiding the effect of impedance discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

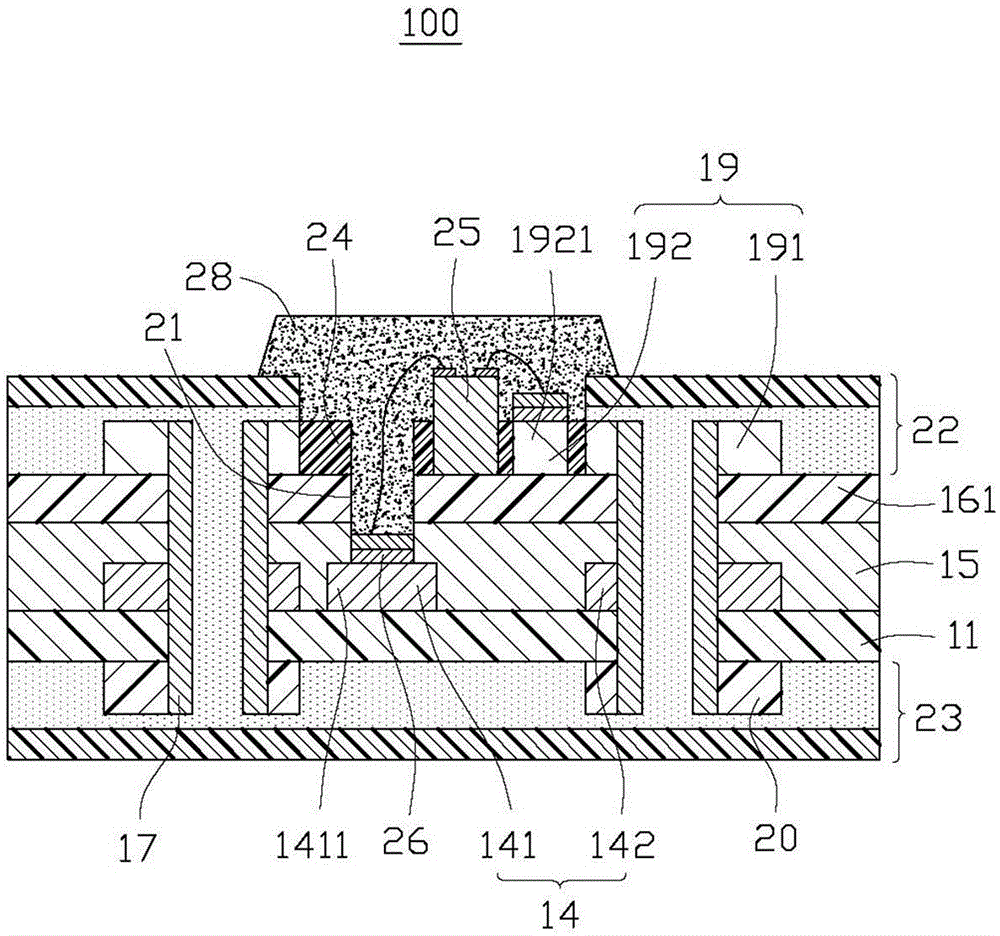

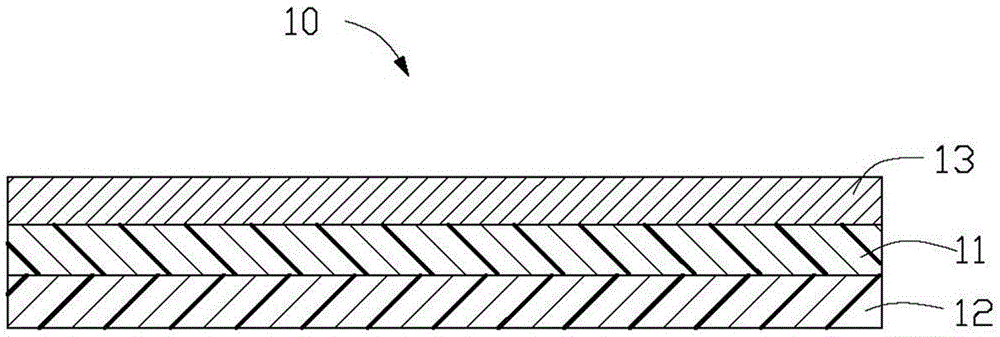

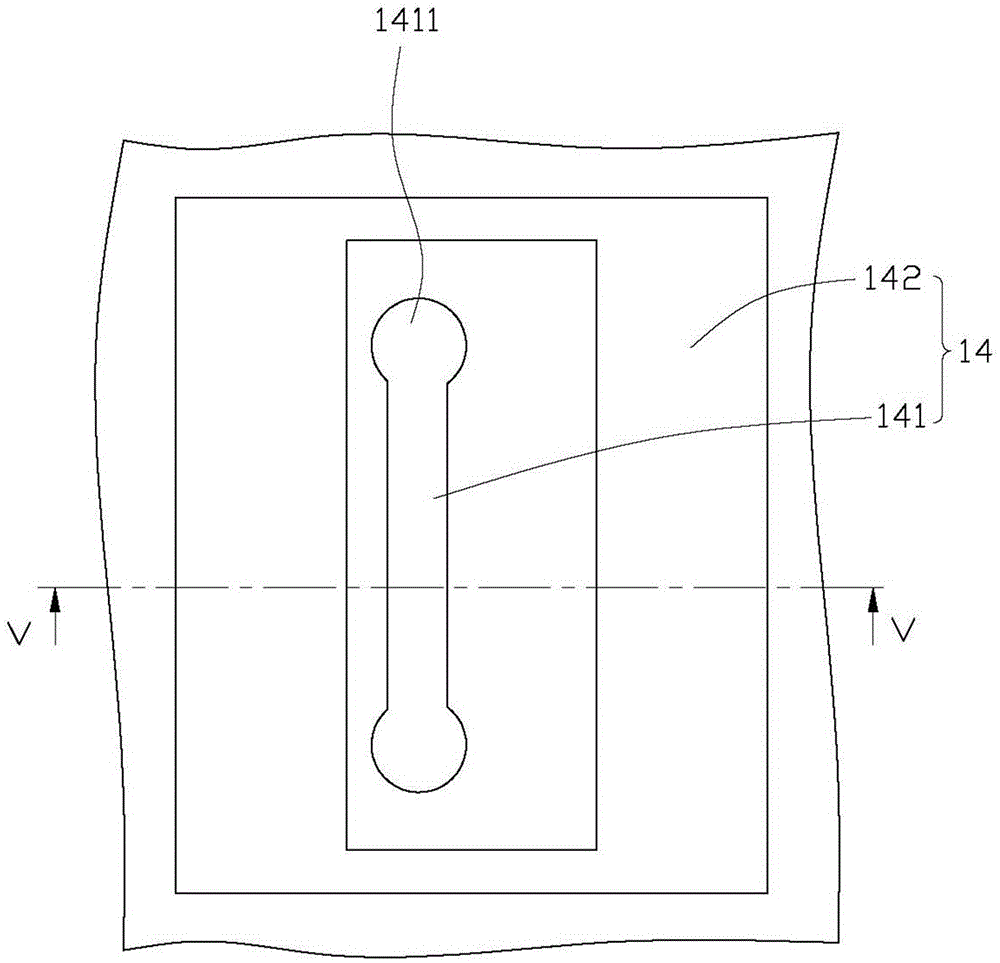

[0025] see figure 1 , Figure 9 and Figure 13 , the first embodiment of the present invention provides a flexible circuit board 100 for high-frequency signal transmission, including: an inner conductive circuit layer 14, a first conductive circuit layer 19 formed on opposite sides of the inner conductive circuit layer 14 and The second conductive circuit layer 20, the second insulating layer 161 and the glue layer 15 formed between the first conductive circuit layer 19 and the inner conductive circuit layer 14, the second conductive circuit layer 20 and the The first insulating layer 11 between the inner conductive circuit layers 14, the first covering film layer 22 formed on the side of the first conductive circuit layer 19 away from the second conductive circuit layer 20, and the first covering film layer 22 formed on the side of the first conductive circuit layer 19 The second conductive circuit layer 20 is away from the second cover film layer 23 , solder resist layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com