Method for manufacturing micro-hollow and micro-bubble rock wool by using basalt as a main ingredient and product of the method

A technology of basalt and micro-bubbles, applied in the manufacture of tools, glass manufacturing equipment, etc., can solve the problems of short fibers, high processing costs, thermal insulation and flame retardancy, poor corrosion resistance, etc., and achieve good toughness, excellent thermal insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

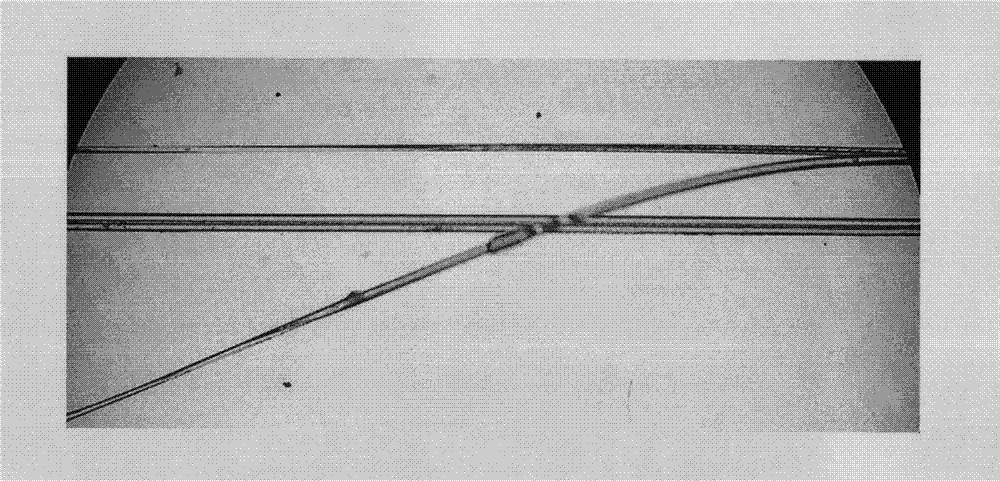

Image

Examples

Embodiment 1

[0013] The first embodiment of the present invention relates to a method for making micro-hollow and micro-bubble rock wool with basalt as the main material.

[0014] The process steps of the method described in the first embodiment of the present invention are: Step 1: start a fire, put the fire starting material in the smelting furnace, put 1 / 2 bottom carbon coke, ignite and stop the wind after 4-10 minutes of air supply, Add the other half of the bottom coke and tamp it down, continue to supply the air for 5-10 minutes, then stop the air supply, and continue to supply the air until the coke is completely ignited; Crushing process, crushing the main material basalt, flux dolomite or limestone into blocks with a diameter of 3-10CM, crushing the selected regulator fluorite and silica stones into blocks with a diameter of 0.5-2CM, and putting the combustion-supporting charcoal Processed into blocks with a particle size of 5-15CM, according to the weight ratio: main material bas...

Embodiment 2

[0026] The second embodiment of the present invention relates to a method for making micro-hollow and micro-bubble rock wool with basalt as the main material.

[0027] The difference between the method of the second embodiment of the present invention and the method of embodiment one is: in the step 2, the selection of raw materials, the ratio of raw materials are different, the raw materials selected are basalt, dolomite, fluorite, according to the weight ratio: The ratio of basalt 66-74%: dolomite 15-26%: fluorite 5-12% is prepared respectively, and the prepared stone and combustion-supporting charcoal are according to the volume ratio: stone 4.5-6: combustion-supporting charcoal 3-4 Prepare the materials separately; Step 3: Loading, the prepared stone and combustion-supporting charcoal are loaded according to the stacked cycle charging method of charcoal first and then material, each group consists of a layer of combustion-supporting charcoal, a layer of dolomite, a layer of...

Embodiment 3

[0030] The third embodiment of the present invention is about the method of making micro-hollow and micro-bubble rock wool with basalt as the main material.

[0031] The difference between the method of present embodiment three and the method of embodiment one is: in step two, the selection of raw material is different with the ratio, and the raw material of choice is according to weight ratio: basalt 60-70%: dolomite 20-28% or limestone 20% -28%: Fluorite 5-10%: The ratio of silica 5-10% is prepared respectively, and the prepared stone and combustion-supporting carbon are according to the volume ratio: stone 4.5-6: The ratio of combustion-supporting carbon 3-4 is respectively Preparation of materials; Step 3: Loading, the prepared stone and combustion-supporting charcoal are loaded according to the stacked circular charging method of first charcoal and then material, each group consists of a layer of combustion-supporting charcoal, a layer of flux, a layer of basalt, A lamina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com