Fabrics for electric welding protective clothing and processing method thereof

A processing method and technology of protective clothing, applied in protective clothing, clothing, clothing and other directions, can solve the problem of blank production and processing methods of electric welding protective clothing fabrics, and achieve the effects of stable flame retardant performance, soft and comfortable fabrics, and good wearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment.

[0026] 1. Selection of raw materials

[0027] Raw material specifications: sulfonamide 2D×51mm; wool 70 S ; Flame-retardant viscose 2D × 51mm.

[0028] 2. Product design

[0029] According to the characteristics of polysulfone fiber, wool fiber and flame-retardant viscose fiber, the yarn fineness is designed to be 50Nm / 2, the blending ratio is 50% polysulfone fiber, 30% wool, and 20% flame-retardant viscose. It is 2 / 1 twill. In order to make the fabric feel smooth and waxy woolen fabric, considering the fabric style and tightness and other factors, the warp density of the fabric is 330 threads / 10cm, the weft density is 278 threads / 10cm, and the width is 155cm. Area density 260 g / m 2 .

[0030] 3. Process flow

[0031] (1) Spinning process flow

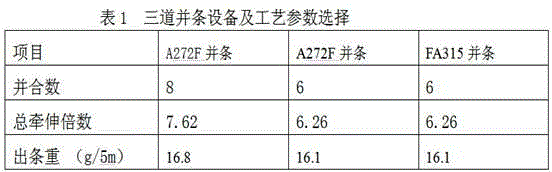

[0032] The semi-worsted process route is adopted, and the process flow is: wool → A186F carding machine → A272F drawing frame → A272...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com