Piecedyed jet black fine-spun facing and preparation method thereof

A worsted fabric and production method technology, applied in the field of wool textiles, can solve the problems of unstable dyeing depth, uniformity and color fastness, difference in color uniformity of fabrics, and inability to handle, so as to improve the dyeing and dyeing rate, The effect of increasing the color group and improving the depth of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

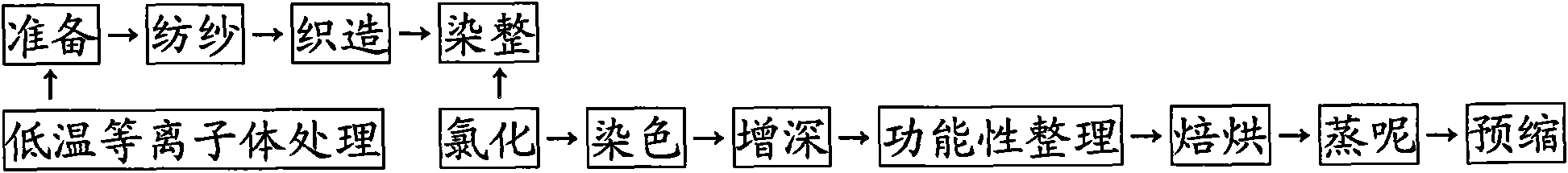

[0104] The piece-dyed extra-black worsted fabric produced in this embodiment is all-wool extra-black gong, and is subjected to three-proof and antistatic functional finishing. The whole wool piece dyed special black tribute cloth of the above specifications is produced through the production processes such as preparation→spinning→weaving→dyeing and finishing.

[0105] 1. Preparation: select all 19.5um (micron) Australian wool fiber tops as raw materials.

[0106] 2. Spinning: spinning warp and weft, warp: 64 s (Public count) / 2, single yarn 710 twists / m, twist direction Z, strands 820 twists / m, twist direction S; weft yarn: 40 s / 1, single yarn 850 twists / m, twist direction S.

[0107] 3. Product specifications: Manufacture of variable twill weave tribute fabric: warp density 380 threads / 10cm, weft density 350 threads / 10cm, cloth width 156cm, fabric weight 220g / square meter.

[0108] 4. Dyeing and finishing:

[0109] (1) Pretreatment: the process steps are as follows:

[0...

Embodiment 2

[0152] In this embodiment, weaving and weaving all-wool Lycra machine washable piece dyed extra black serge, the specifications are as follows:

[0153] All-wool Lycra machine washable piece-dyed super black serge fiber raw material blending ratio of 97.5% 18.5um Australian wool fiber and 2.5% Lycra fiber, warp 78 s / 2, single yarn 780 twists / m, twist direction Z, strands 920 twists / m, twist direction S twist, weft yarn 50 s / 1, single yarn 1050 twists / m, twist direction S, 2 / 1 twill weave, warp density 360 threads / 10cm, weft density 350 threads / 10cm, fabric width 152cm, fabric weight 185g / square meter, and Carry out three-proof, machine washable functional finishing.

[0154] This example is similar to Example 1 in the production process of preparation→spinning→weaving→dyeing and finishing. The difference from Example 1 is that the selected 18.5um Australian wool fiber is changed in the preparation process. Raw tops are subjected to chlorination, which comprises the followi...

Embodiment 3

[0194] This example is basically similar to Example 2. It is made of wool-polyester conductive three-proof piece dyed black veritin. The specifications of different fabrics are as follows:

[0195] The blending ratio of fiber raw materials is 70% of 20.5um mercerized wool, 29.2% of 3D (denier) polyester and 0.8% of conductive fiber, warp yarn 56 s / 2, single yarn 620 twist / m, twist direction Z, strand 660 twist / m, twist direction S twist, weft yarn is the same as warp yarn, 1 / 1 plain weave, warp density 240 / 10cm, weft density 220 / 10 cm, cloth width 152 cm. The weight of the fabric is 170 grams per square meter, and it must be finished with three anti-functions.

[0196] The difference between the production process of this example and Example 2 is: the production method of wool-polyester conductive three-proof piece dyed special black veritin, including production processes such as combing, spinning, weaving, dyeing and finishing, and the selection ratio of the preparation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com