Low temperature dyeing method for wool fibre

A wool fiber, low temperature dyeing technology, applied in the field of textile dyeing and finishing, can solve problems such as strong corrosion, wool fiber damage, and fiber physical and mechanical properties decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

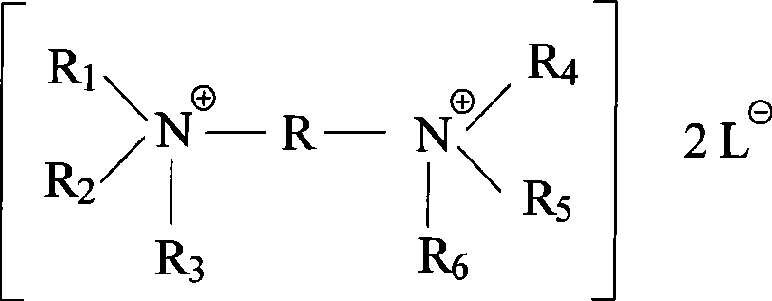

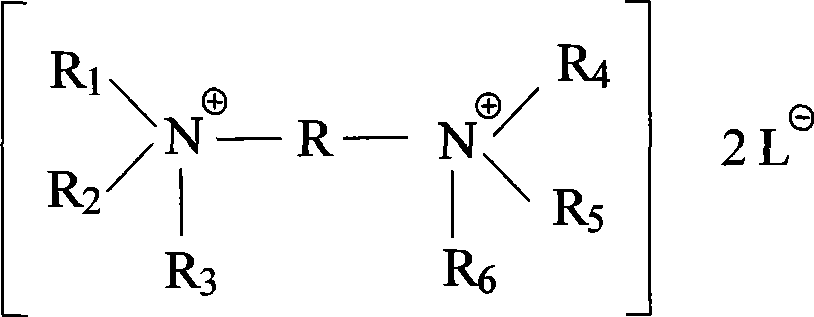

[0051] Wool loose fiber: put 100Kg of loose fiber into the intermittent wool dyeing machine, the liquor ratio is 1:25, add 1Kg of acid dye, 5Kg of sodium sulfate, 1Kg of high-efficiency penetrating agent SP-2 and 0.6Kg of wool at 40°C A kind of gemini cationic surfactant, adding an appropriate amount of acetic acid to control the pH value of the solution to 4.5-5. Raise the temperature to 80°C at a rate of 1°C to 2°C per minute, and run for 45 minutes. Turn on the water, then soap with 70°C alkaline soap for 15 minutes, and continue to wash with 50°C water for 15 minutes. Out of the cylinder, dehydrated on a centrifugal dehydrator, and dried.

Embodiment 2

[0053] Wool loose fiber: put 100Kg loose fiber into the intermittent wool dyeing machine, the bath ratio is 1:25, add 1Kg wool reactive dye, 1.5Kg ammonium sulfate, 5Kg sodium sulfate, 0.5Kg flatin at 40°C The mixture of O and 0.8Kg two kinds of gemini cationic surfactants, the mixing ratio of the two is 1:1. Raise the temperature to 80°C at a rate of 1°C to 2°C per minute, and run for 60 minutes. Continue to add 25% ammonia water to adjust the pH of the solution to 8-8.5, and treat at 80° C. for 20 minutes. Turn on the water, then soap with 70°C alkaline soap for 15 minutes, and continue to wash with 50°C water for 15 minutes. Out of the cylinder, dehydrated on a centrifugal dehydrator, and dried.

Embodiment 3

[0055] Wool yarn (60 counts): put 100Kg of yarn into the intermittent wool top dyeing machine with a liquor ratio of 1:30, add 1Kg of acid dye, 6Kg of sodium sulfate, and 1.2Kg of high-efficiency penetrating agent SP- 2 and 0.7Kg a kind of gemini cationic surfactant, add appropriate amount of acetic acid to control the pH value of the solution to be 4.5-5. Raise the temperature to 80°C at a rate of 1°C to 2°C per minute, and run for 45 minutes. Turn on the water, then soap with 70°C alkaline soap for 15 minutes, and continue to wash with 50°C water for 15 minutes. Out of the cylinder, dehydrated on a centrifugal dehydrator, and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com