LED lamp based on transparent fluorescent ceramics

A technology of LED lamps and fluorescent ceramics, which is applied in parts of lighting devices, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc. problem, to achieve the effect of improving heat dissipation, efficient and stable light emission, and solving thermal and light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

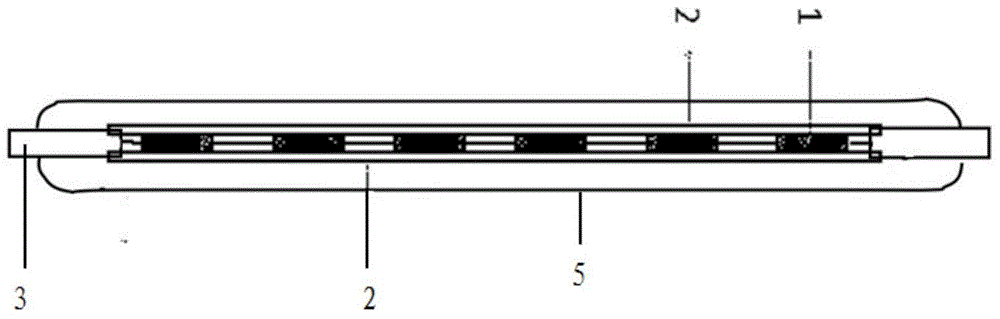

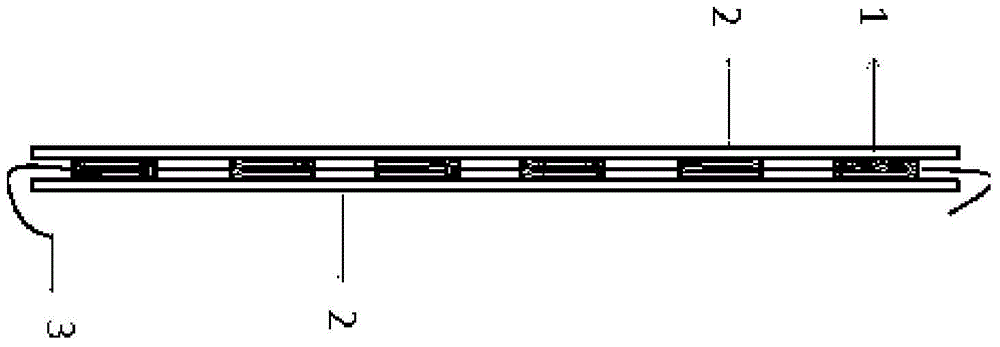

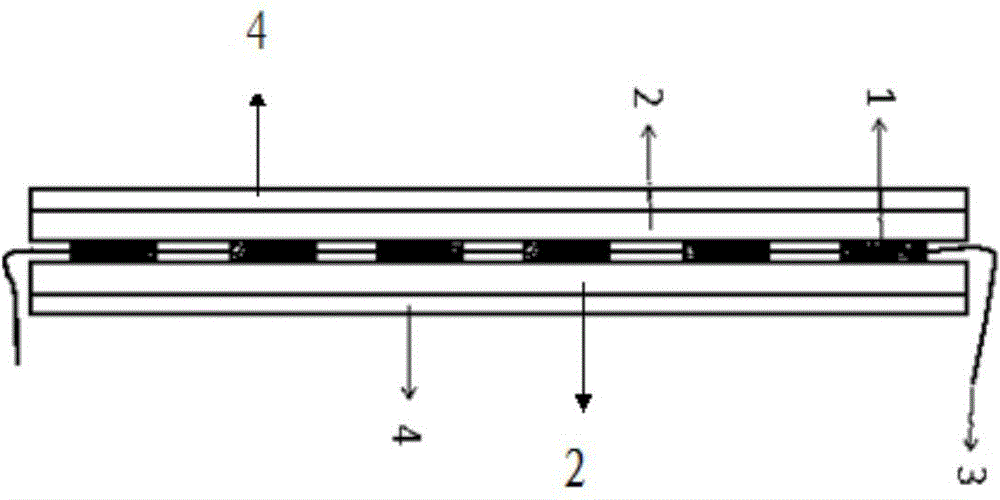

[0018] The upper and lower fluorescent ceramic strips 2 use: Ce:YAG fluorescent ceramics processed into two long thin slices of 30mm×1.5mm×0.38mm, such as figure 2 As shown, an LED filament is formed. Because the thermal conductivity of Ce:YAG fluorescent ceramics is much higher than that of glass, plastic and other substrates, it can improve the heat dissipation of LED filament lamps to a certain extent. Moreover, fluorescent ceramics do not have the problems of aging and discoloration of traditional fluorescent powder + silica gel (or resin) packaging. More importantly, Ce:YAG fluorescent ceramics can also effectively improve the light attenuation problem under the appropriate doping concentration, which can guarantee the LED The filament lamp has long-term stable working performance and service life.

Embodiment 2

[0020] The upper and lower fluorescent ceramic strips 2 use: Ce, Pr: YAG fluorescent ceramics processed into two long thin slices of 30mm×1.5mm×0.38mm, such as figure 2 As shown, an LED filament is formed.

Embodiment 3

[0022] In the upper and lower fluorescent ceramic strips 2, Ce, Cr: YAG fluorescent ceramics are processed into two strips of 40mm×2mm×0.38mm, such as figure 2 As shown, an LED filament is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com