Organic light-emitting display device and method of fabricating the same

An electroluminescent device, an organic technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as distance difference, uneven brightness, poor brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

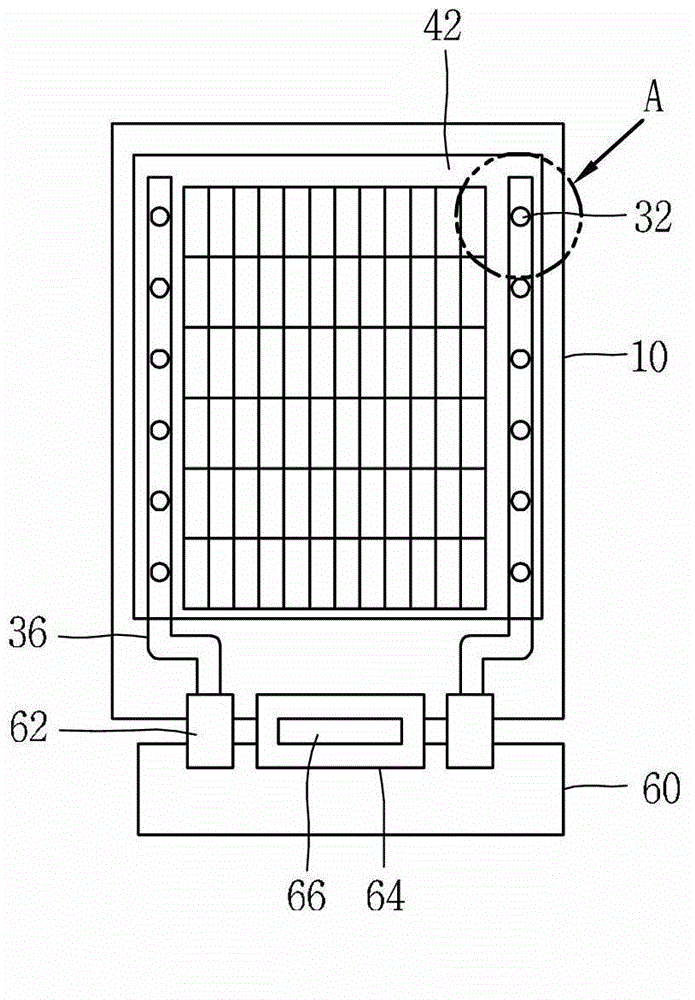

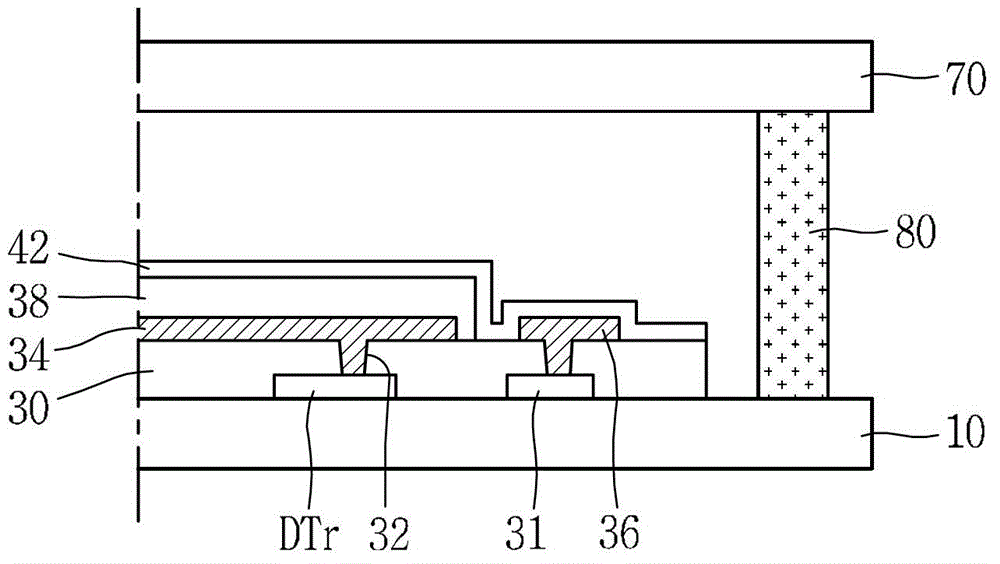

[0026] Figure 4 is a cross-sectional view showing one pixel region including a driving thin film transistor of an organic electroluminescence device according to an embodiment of the present invention. Figure 5 is a sectional view showing an actual pressure drop preventing pattern and banks. Figure 6A to Figure 6E is a plan view showing the shape of the pressure drop prevention pattern according to the embodiment of the present invention.

[0027] refer to Figure 4 , the organic electroluminescent device according to an embodiment of the present invention is a top emission type, and the organic electroluminescent device includes a driving and switching transistor (DTr) (as described below, 113, 114 and 115 are combined to form the transistor), The first substrate 110 on which the organic electroluminescent diode (D) and the second substrate 170 for encapsulation are formed.

[0028] A buffer layer 112 is formed on the driving area (DA) of the first substrate 110 . On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com