Machine for making soya-bean milk easy to clean

A soymilk maker and easy-to-clean technology, which can be used in milk replacers, beverage preparation devices, household appliances, etc., and can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

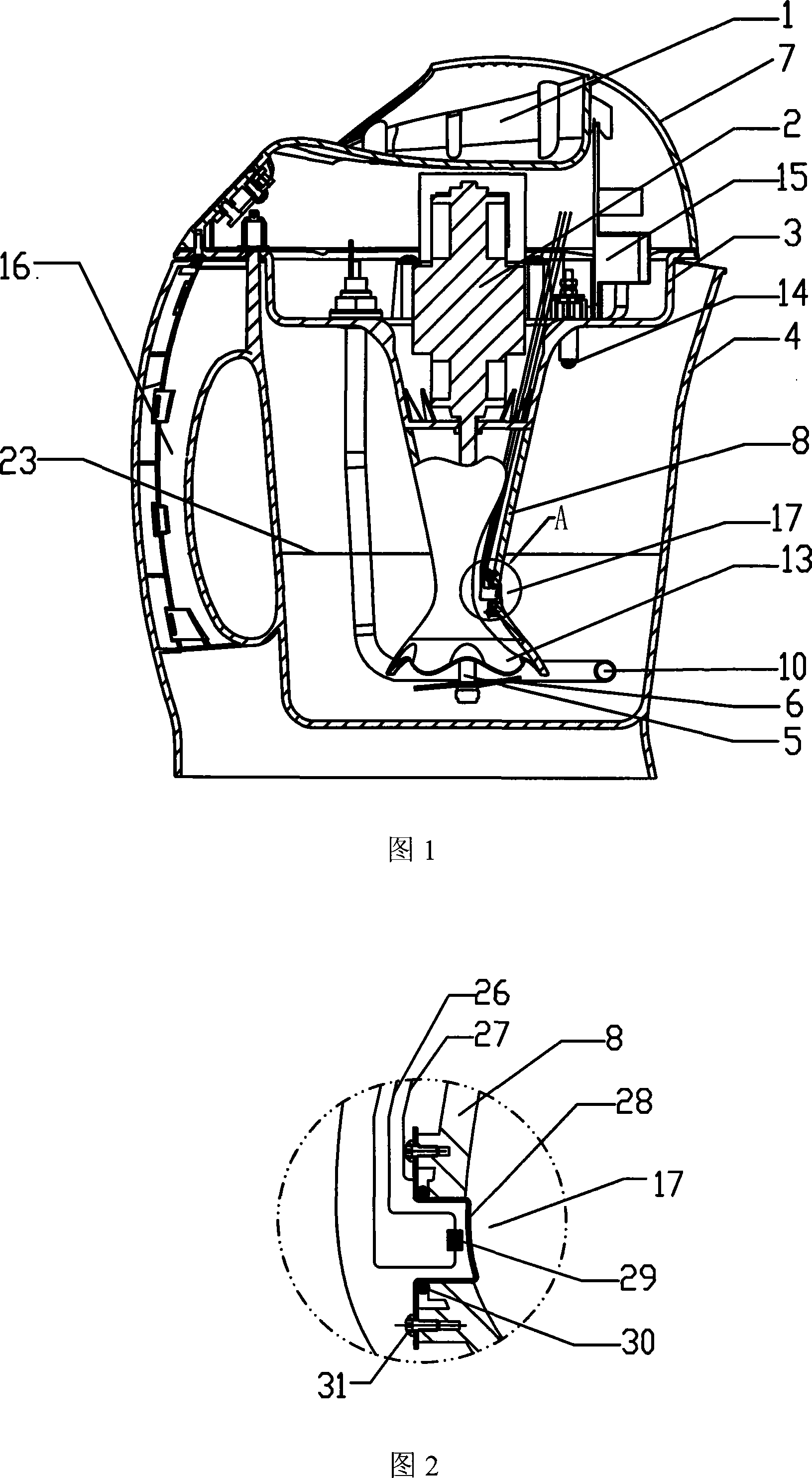

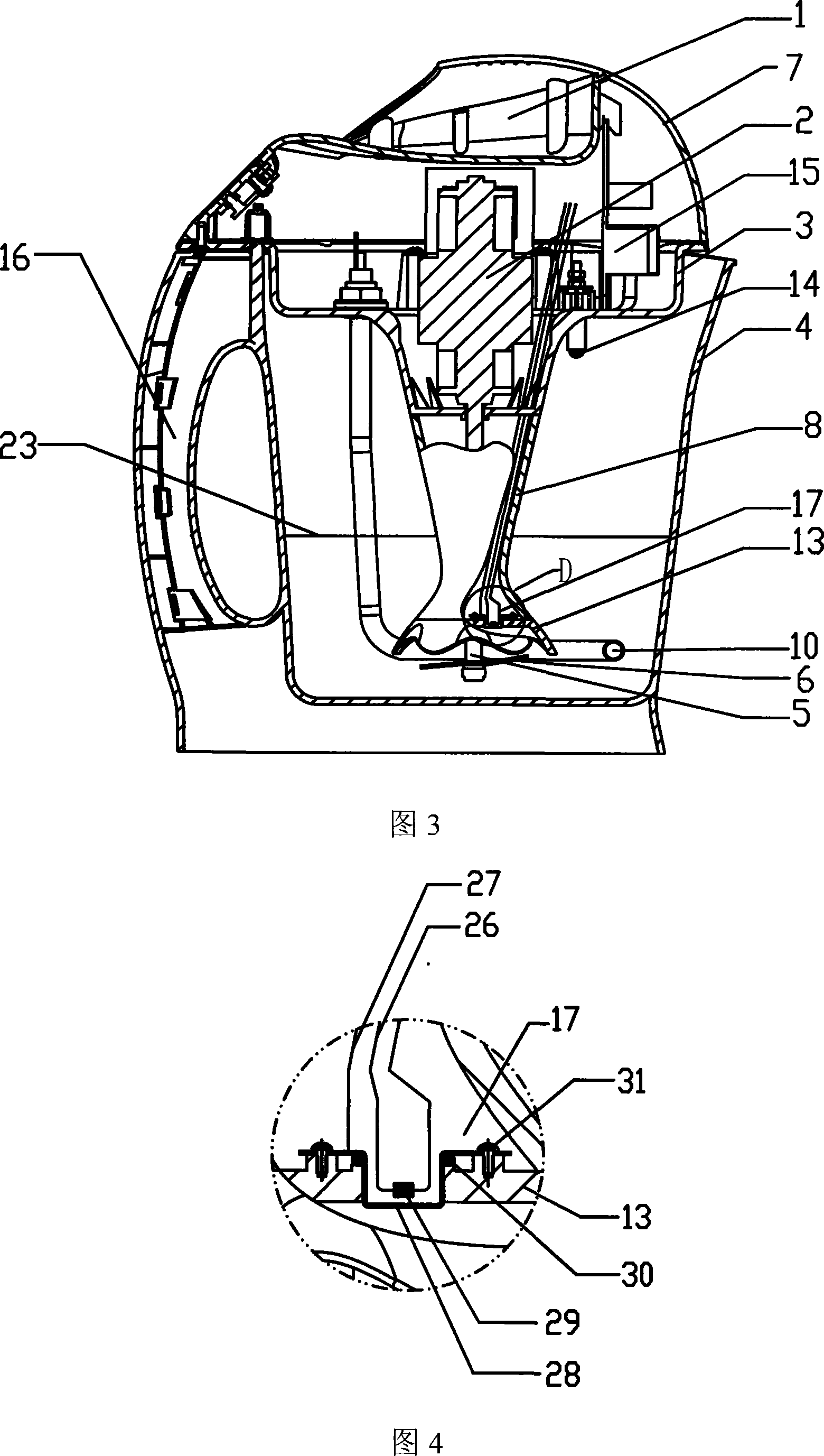

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] As shown in Fig. 1 and Fig. 2, the first embodiment of the easy-to-clean soybean milk machine of the present invention includes a machine head 1, a cup body 4, a handle 16, a motor 2, a crushing knife 6, a heating tube 10 and a control circuit board 15. The head 1 is buckled on the cup body 4, the motor 2 is fixedly arranged in the machine head 1, the end of the motor shaft 5 is fixed with a crushing knife 6, the machine head 1 includes the machine head upper cover 7 and the machine head lower cover 3, the machine head lower cover 3 The lower ends are respectively fixed with the anti-overflow electrode 14 and the connecting body 8 with a hollow. The lower end of the connecting body 8 is fixed with a spoiler curved surface body 13, and the spoiler curved surface body 13 is located above the pulverizer 6. 13 The part below the water level 23 forms a cavity isolated fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com