Radiator for electronic or electric products and manufacturing method thereof

A technology of electrical products and manufacturing methods, applied in the direction of electrical components, electrical solid devices, cooling/ventilation/heating transformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention are now described with reference to the drawings, wherein like parts use like reference numerals throughout.

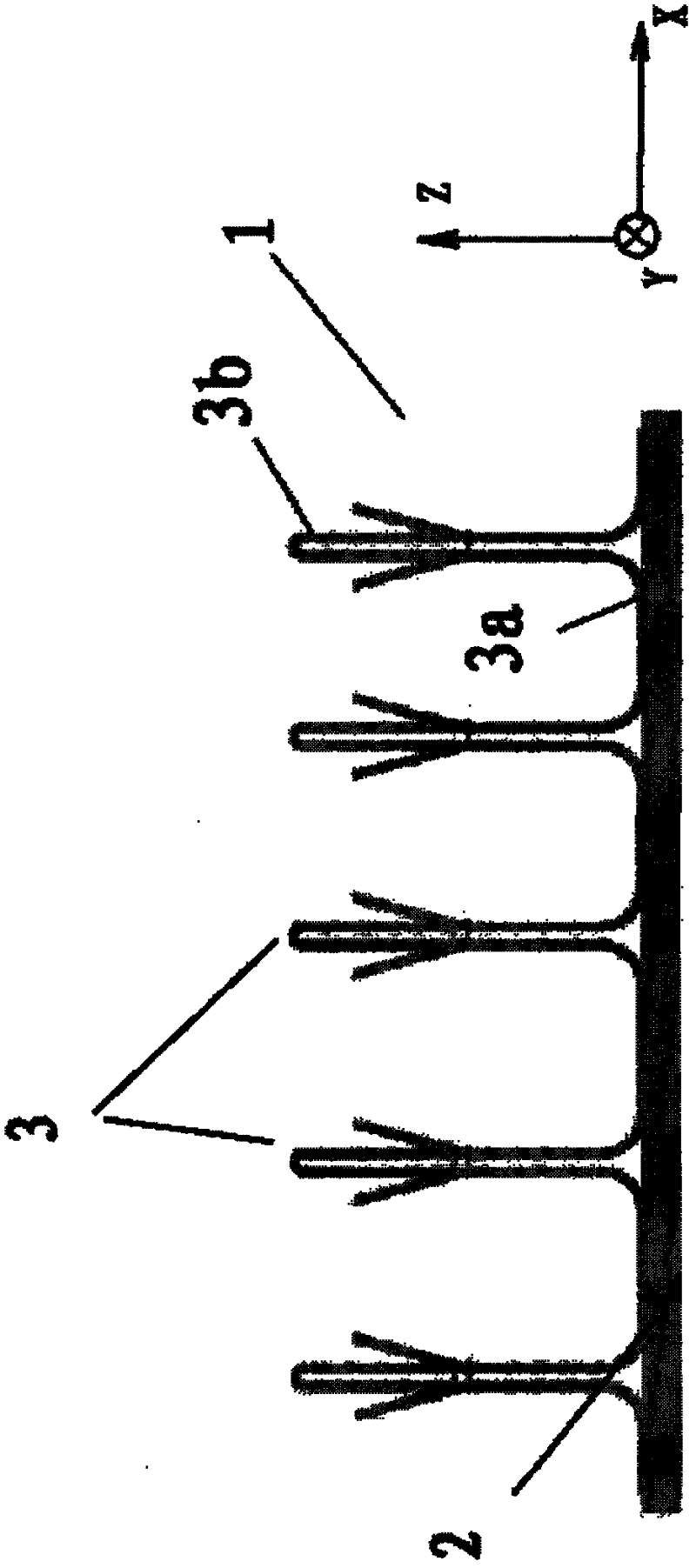

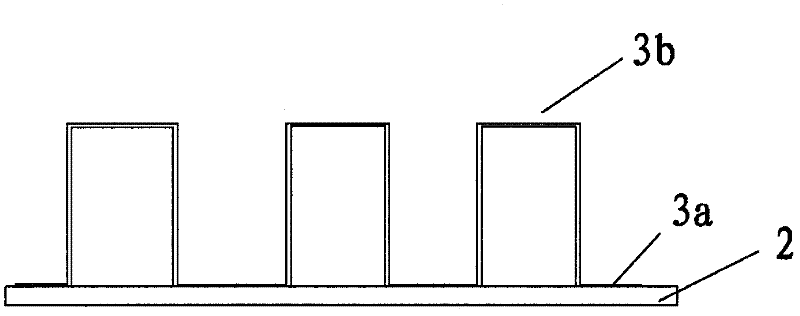

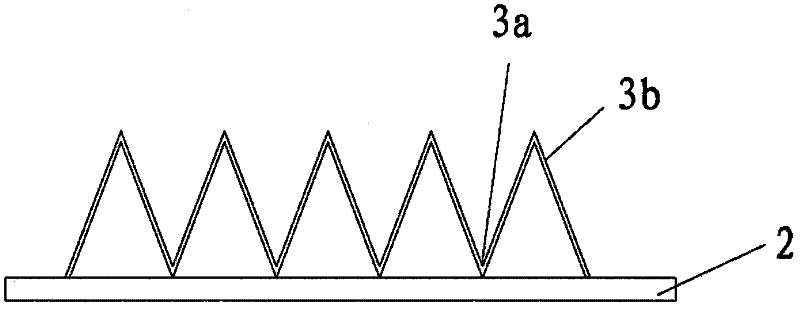

[0043] A non-limiting exemplary embodiment of the heat sink of the present invention is in figure 1 , where the heat sink 1 includes two main components, namely the base plate 2 and the fins 3 . For the convenience of description below, the direction along the thickness of the fin 3 is called the x-axis direction, the direction along the length of the fin 3 is called the y-axis direction, and the direction along the height of the fin 3 is called the z-axis direction.

[0044] The base plate 2 is made of metal and is used to contact a heat source. The base plate 2 can be solid, or the base plate 2 can have at least one cooling channel arranged inside it, which is filled with a flowable cooling medium.

[0045] The fin material of the fin 3 is a metal plate, and includes periodically arranged connecting portions 3 a and fin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com