Method for manufacturing multi-layer amorphous alloy and crystal metal composite structure through diffusion welding

An amorphous alloy and diffusion welding technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of limited application value of materials, poor shear resistance, and high brittleness of amorphous alloy materials, and achieve Ease of popularization and use, enhanced toughness, and improved shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

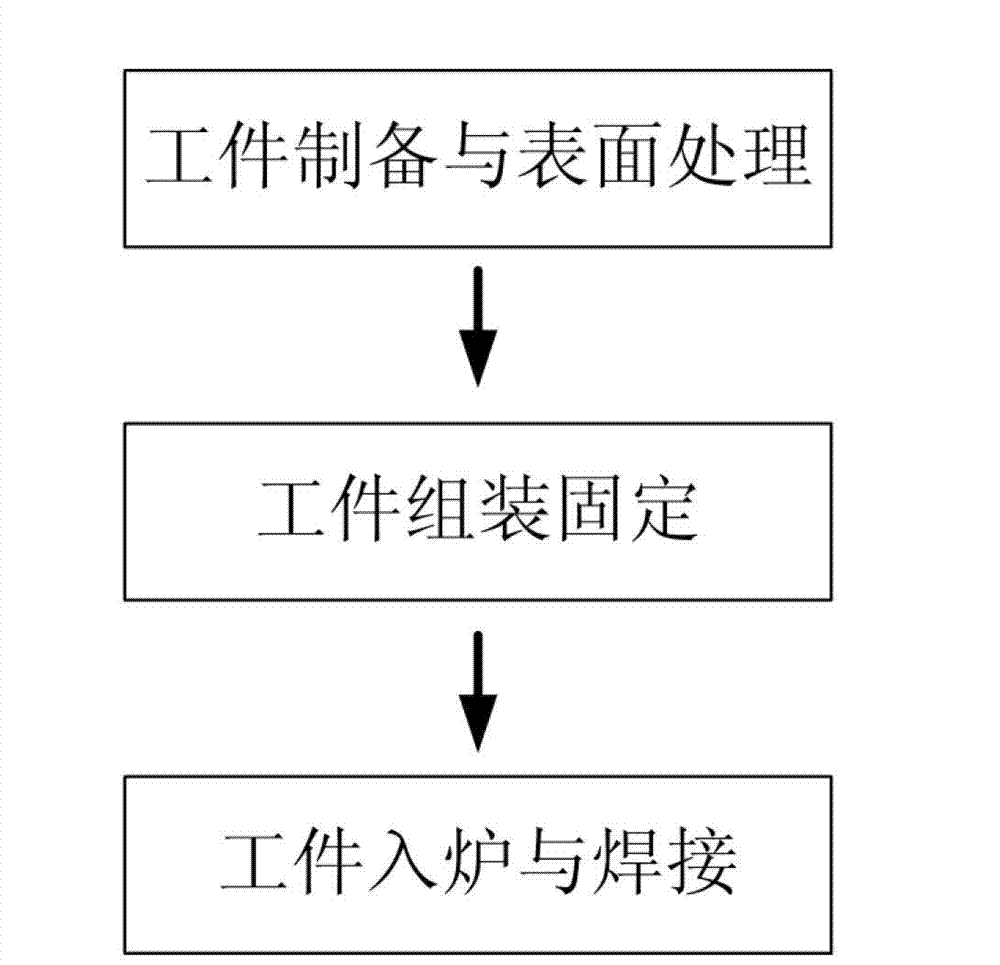

Method used

Image

Examples

Embodiment 1

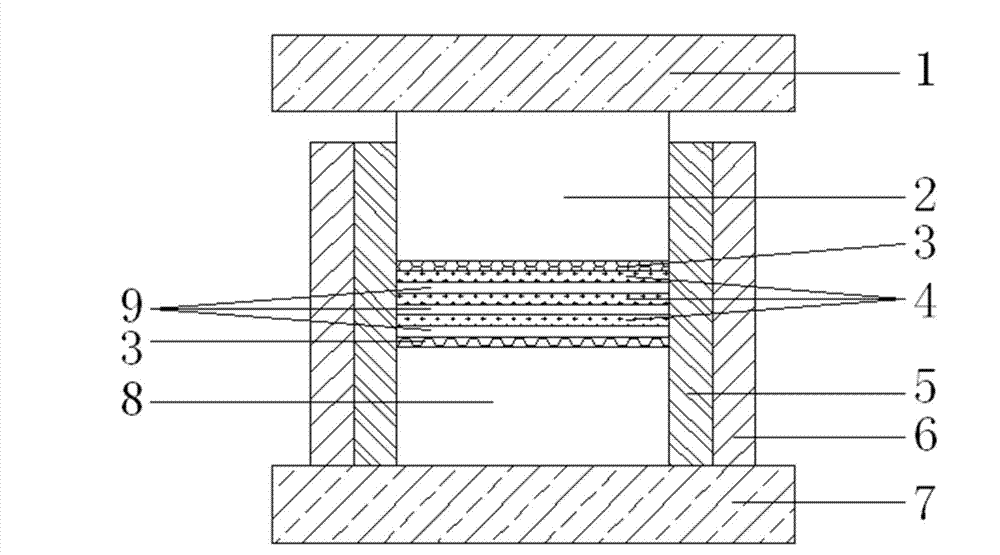

[0053] First, Zr with a thickness of 0.2mm 41 Ti 14 Cu 12.5 Ni 10 be 22.5Flakes and zirconium flakes are cut into specified sizes, and the end faces of workpieces are polished with 800#, 1000#, and 1200# sandpaper in sequence. After processing, the parallelism is better than 0.02mm, polished to a roughness of better than 1.6um, and the oxide layer is removed. Put the workpiece in acetone and ultrasonically clean it for 15 minutes. After taking out the workpiece, put it into absolute ethanol for the second ultrasonic cleaning, and then put the cleaned workpiece into clean absolute ethanol for storage. On the WC cemented carbide lower indenter, place the solder stop layer in sequence from bottom to top, and place Zr crosswise. 41 Ti 14 Cu 12.5 Ni 10 be 22.5 Flakes, zirconium flakes, solder stop layer, and finally place the WC hard alloy upper indenter, put on the mold combination jacket and the mold jacket to form a fixed workpiece. Place the fixed workpiece in a vacuum...

Embodiment 2

[0055] First, Zr with a thickness of 0.2mm 41 Ti 14 Cu 12.5 Ni 10 be 22.5 Flakes and zirconium flakes are cut into specified sizes, and the end faces of workpieces are polished with 800#, 1000#, and 1200# sandpaper in sequence. After processing, the parallelism is better than 0.02mm, polished to a roughness of better than 1.6um, and the oxide layer is removed. Put the workpiece in acetone and ultrasonically clean it for 15 minutes. After taking out the workpiece, put it into absolute ethanol for the second ultrasonic cleaning, and then put the cleaned workpiece into clean absolute ethanol for storage. On the WC cemented carbide lower indenter, place the solder stop layer in sequence from bottom to top, and place Zr crosswise. 41 Ti 14 Cu 12.5 Ni 10 be 22.5 Flakes, zirconium flakes, solder stop layer, and finally place the WC hard alloy upper indenter, put on the mold combination jacket and the mold jacket to form a fixed workpiece. Place the fixed workpiece in a vacuu...

Embodiment 3

[0057] First, Zr with a thickness of 0.2mm 55 Cu 30 Al 10 Ni 5 Flakes and zirconium flakes are cut into specified sizes, and the end faces of workpieces are polished with 800#, 1000#, and 1200# sandpaper in sequence. After processing, the parallelism is better than 0.02mm, polished to a roughness of better than 1.6um, and the oxide layer is removed. Put the workpiece in acetone and ultrasonically clean it for 15 minutes. After taking out the workpiece, put it into absolute ethanol for the second ultrasonic cleaning, and then put the cleaned workpiece into clean absolute ethanol for storage. On the WC cemented carbide lower indenter, place the solder stop layer in sequence from bottom to top, and place Zr crosswise. 55 Cu 30 Al 10 Ni 5 Flakes, zirconium flakes, solder stop layer, and finally place the WC hard alloy upper indenter, put on the mold combination jacket and the mold jacket to form a fixed workpiece. Place the fixed workpiece in a vacuum diffusion welding furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com