Inorganic high-temperature fused salt corrosion resistant graphene paint and preparation method thereof

An inorganic high temperature resistance and molten salt corrosion technology, applied in the field of coatings, can solve the problems of poor compactness, long construction period, high cost of 45CT, etc., and achieve the effect of stable performance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

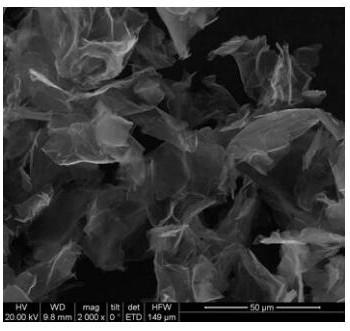

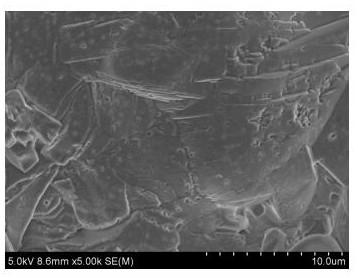

Image

Examples

Embodiment 1

[0043] A kind of graphene coating of inorganic high-temperature molten salt corrosion resistance is prepared by the following method:

[0044] (1) 8 parts of aluminum dihydrogen phosphate with a solid content of 50%, 9 parts of magnesium dihydrogen phosphate with a solid content of 50%, 10 parts of aluminum chromium phosphate with a solid content of 50%, and 20 parts of zirconium sol with a solid content of 30% Slowly mix and stir evenly to obtain a high-temperature adhesive;

[0045] (2) Mix 0.1 part of 5 μm graphene powder, 0.2 part of CTAB and 7.7 parts of deionized water, and use ultrasonic emulsification disperser to ultrasonically emulsify for more than 30 minutes to prepare graphene dispersion;

[0046] (3) The high-temperature adhesive obtained in step (1), the graphene dispersion obtained in step (2), 7 parts of 10 μm aluminum tripolyphosphate, 6 parts of 10 μm zinc phosphate, 2 parts of 0.3 mm zirconia fiber, and 1 part of 0.5 mm silicon oxide Fiber and 20 parts of ...

Embodiment 2

[0050] A kind of graphene coating of inorganic high-temperature molten salt corrosion resistance is prepared by the following method:

[0051] (1) 20 parts of aluminum dihydrogen phosphate with a solid content of 50%, 7 parts of magnesium dihydrogen phosphate with a solid content of 50%, 8 parts of zinc dihydrogen phosphate with a solid content of 50%, and 7 parts of phosphoric acid with a solid content of 50% Aluminum chromium and 10 parts of zirconium sol with a solid content of 30% are slowly mixed and stirred evenly to prepare a high-temperature adhesive;

[0052] (2) Mix 0.2 parts of 15 μm graphene powder, 0.5 parts of NMP and 8.3 parts of deionized water, and use ultrasonic emulsification disperser to ultrasonically emulsify for more than 1 min to prepare graphene dispersion;

[0053] (3) The high-temperature adhesive obtained in step (1), the graphene dispersion obtained in step (2), 2 parts of 5 μm aluminum tripolyphosphate, 4 parts of 15 μm dichromium oxide, 3 parts o...

Embodiment 3

[0057] A kind of graphene coating of inorganic high-temperature molten salt corrosion resistance is prepared by the following method:

[0058] (1) 15 parts of magnesium dihydrogen phosphate with a solid content of 50%, 10 parts of zinc dihydrogen phosphate with a solid content of 50%, 10 parts of aluminum chromium phosphate with a solid content of 50%, and 15 parts of zirconium sol with a solid content of 30% Slowly mix and stir evenly to obtain a high-temperature adhesive;

[0059] (2) Mix 0.28 parts of 5 μm graphene powder, 0.56 parts of CTAB and 3.16 parts of deionized water, and use a ultrasonic emulsification disperser to ultrasonically emulsify for more than 1 min to prepare a graphene dispersion;

[0060] (3) The high-temperature adhesive obtained in step (1), the graphene dispersion obtained in step (2), 5 parts of 15 μm aluminum tripolyphosphate, 3 parts of 5 μm dichromium oxide, 4 parts of 5 μm zinc phosphate, and 4 parts of 0.1 mm zirconium oxide Fiber, 3 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| corrosion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com