Waterproof reinforcing alkali-free liquid setting accelerator and preparation method thereof

An enhanced, quick-setting agent technology, applied in the field of building materials, can solve the problems of poor stability and low strength of the accelerator, and achieve the effects of low rebound rate, improved stability, and improved early and later strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

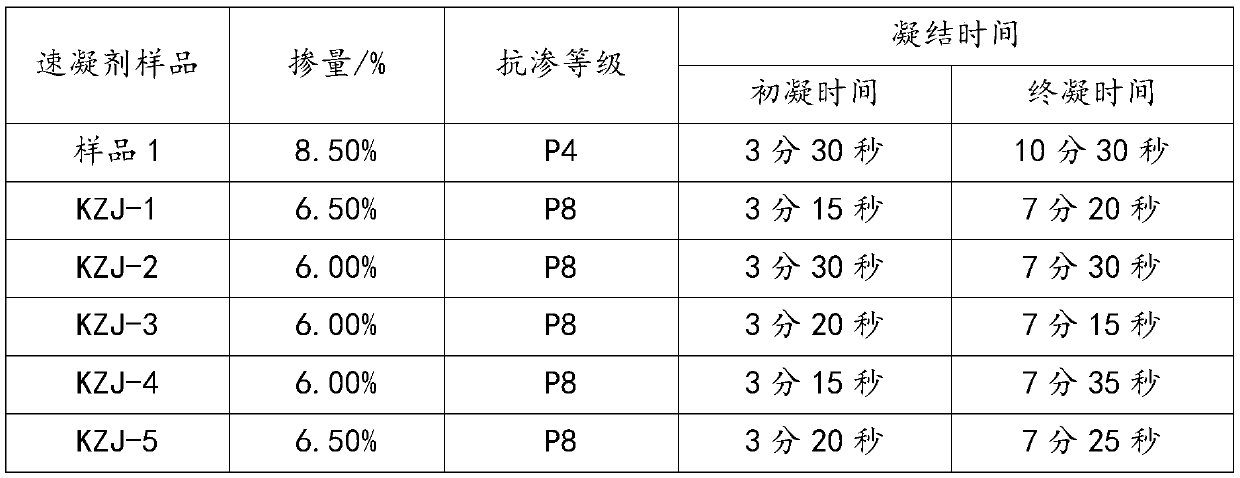

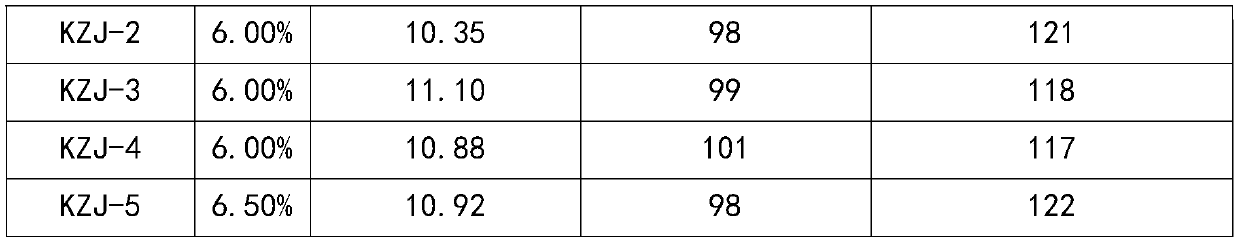

Examples

Embodiment 1

[0021] (1) Preparation of modified aluminate: Add 18.00g of stearic acid into the reaction kettle, heat up to 70°C, heat to a molten state, turn on the stirring device, then add 6.00g of ammonia water at one time, stir evenly, and react 3.0 h, when the temperature is lowered to 35°C, add 20.00g of aluminum ammonium sulfate, 12.00g of aluminum isopropoxide and 37.00g of water to the reaction kettle, carry out ultrasonic reaction for 3h, drop to normal temperature, then add 7.00g of calcium hydroxide, react for 0.5h, A modified aluminate is obtained.

[0022] (2) Preparation of stabilizer: add 100.00g (trimethylsilyl) acetic acid to the reaction kettle, turn on the stirring device, then add 97.00g 2-(methylamino)ethanol and 3.20g concentrated sulfuric acid at one time, stir After uniformity, start to raise the temperature, raise the temperature to 65°C and react for 5.0 hours, then add 73.00 g of monoethanolamine and continue the reaction for 3.0 hours to obtain a stabilizer;

...

Embodiment 2

[0025] (1) Preparation of modified aluminate: Add 20.00g of stearic acid into the reaction kettle, heat up to 72°C, heat to molten state, turn on the stirring device, then add 7.00g of ammonia water at one time, stir evenly, and react 2.0 h, when the temperature is lowered to 40°C, add 25.00g of aluminum ammonium sulfate, 15.00g of aluminum isopropoxide and 26.00g of water to the reaction kettle, carry out ultrasonic reaction for 2h, drop to normal temperature, then add 7.00g of calcium hydroxide, react for 0.5h, A modified aluminate is obtained.

[0026] (2) Preparation of stabilizer: add 100.00g (trimethylsilyl) acetic acid to the reaction kettle, turn on the stirring device, then add 159.00g 2-(diisopropylamino)ethanol and 4.60g concentrated sulfuric acid at one time, stir After uniformity, start to raise the temperature, raise the temperature to 60°C and react for 4.0 hours, then add 105.00 g of diethanolamine and continue the reaction for 4.0 hours to obtain a stabilizer....

Embodiment 3

[0029] (1) Preparation of modified aluminate: Add 20.00g of stearic acid into the reaction kettle, heat up to 75°C, heat to molten state, turn on the stirring device, then add 8.00g of ammonia water at one time, stir evenly, and react 4.0 h, when the temperature is lowered to 40°C, add 30.00g of aluminum ammonium sulfate, 14.00g of aluminum isopropoxide and 20.00g of water into the reaction kettle, carry out ultrasonic reaction for 4h, drop to normal temperature, then add 8.00g of calcium hydroxide, react for 0.5h, A modified aluminate is obtained.

[0030] (2) Preparation of stabilizer: add 100.00g (trimethylsilyl) acetic acid to the reaction kettle, turn on the stirring device, then add 124.00g 2-(ethylamino)ethanol and 2.80g p-toluenesulfonic acid at one time, stir After uniformity, start to raise the temperature, raise the temperature to 75°C and react for 3.0 hours, then add 119.00 g of triethanolamine and continue the reaction for 2.0 hours to obtain a stabilizer.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com