Inorganic high-temperature resistant and antistatic coating

An inorganic high temperature resistant and antistatic technology, applied in the direction of coating, etc., can solve problems such as peeling, strength reduction, and inability to effectively protect high-speed aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

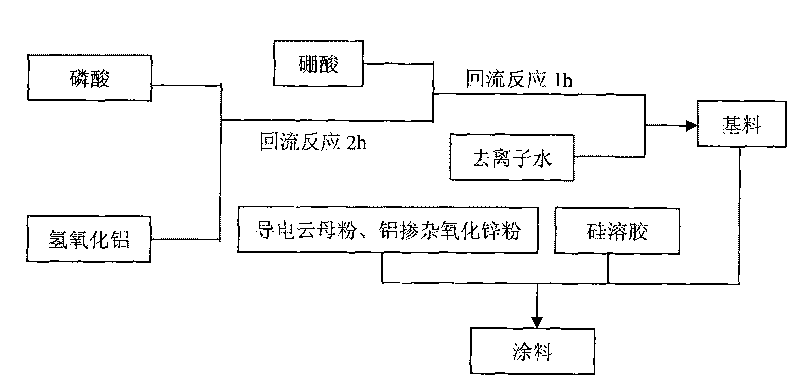

[0017] First add 140.0g of phosphoric acid (85%) and 35.0g of aluminum hydroxide in the reaction flask, heat up and reflux for 2 hours, then add 12.0g of boric acid, continue to reflux for 1 hour and then cool down, add 100.0g of deionized water after the temperature of the system is less than 60°C , to make the base material.

[0018] Dissolve 10.0g of titanate coupling agent in 450.0g of 95% ethanol, mix with 65.0g of conductive mica powder and 35.0g of aluminum-doped zinc oxide powder and stir evenly, and place it in an environment of 60±2°C for 4 hours. Ethanol and water are then distilled off under reduced pressure to prepare a mixture of conductive mica powder and aluminum-doped zinc oxide powder.

[0019] Take 35.0 g of a mixture of 100.0 g of base material, 100.0 g of silica sol (45%), treated conductive mica powder, and aluminum-doped zinc oxide powder to prepare a coating.

[0020] Test the related properties of coating and film formation: surface resistance 9.8×10 ...

Embodiment 2

[0022] First add 140.0g of phosphoric acid (85%) and 35.0g of aluminum hydroxide in the reaction flask, heat up and reflux for 2 hours, then add 12.0g of boric acid, continue to reflux for 1 hour and then cool down, add 100.0g of deionized water after the temperature of the system is less than 60°C , to make the base material.

[0023] Dissolve 10.0g of titanate coupling agent in 450.0g of 95% ethanol, mix with 65.0g of conductive mica powder and 35.0g of aluminum-doped zinc oxide powder and stir evenly, and place it in an environment of 60±2°C for 4 hours. Ethanol and water are then distilled off under reduced pressure to prepare a mixture of conductive mica powder and aluminum-doped zinc oxide powder.

[0024] Take 35.0 g of a mixture of 100.0 g of base material, 70.0 g of silica sol (45%), treated conductive mica powder, and aluminum-doped zinc oxide powder to prepare a coating.

[0025] Test the related properties of coating and film formation: surface resistance 5.9×10 ...

Embodiment 3

[0027] First add 140.0g of phosphoric acid (85%) and 42.0g of aluminum hydroxide to the reaction flask, heat up and reflux for 2 hours, then add 12.0g of boric acid, continue to reflux for 1 hour and then cool down. Add 100.0g of deionized water after the temperature of the system is less than 60°C , to make the base material.

[0028] Dissolve 10.0g of titanate coupling agent in 450.0g of 95% ethanol, mix with 65.0g of conductive mica powder and 35.0g of aluminum-doped zinc oxide powder and stir evenly, and place it in an environment of 60±2°C for 4 hours. Ethanol and water are then distilled off under reduced pressure to prepare a mixture of conductive mica powder and aluminum-doped zinc oxide powder.

[0029] Take 35.0 g of a mixture of 100.0 g of base material, 90.0 g of silica sol (45%), treated conductive mica powder, and aluminum-doped zinc oxide powder to prepare a coating.

[0030] Test the related properties of coating and film formation: surface resistance 8.2×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com