Low-chloride and low-alkali composite cement grinding aid and preparation method thereof

A compound cement and grinding aid technology, applied in the field of cement production, can solve the problems of high production cost, restricting the popularization of industrialization, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

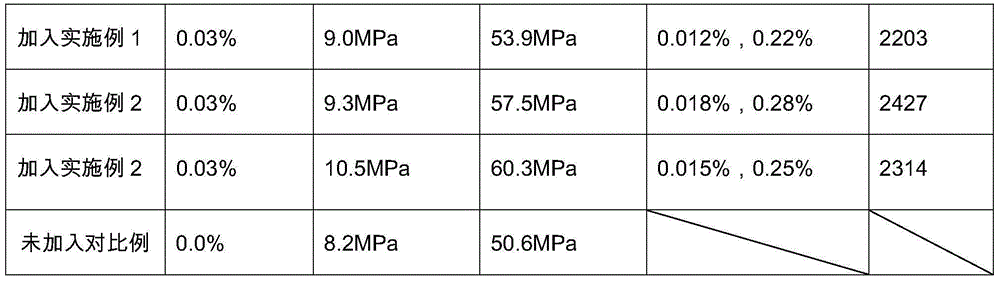

Embodiment 1

[0016] Low-chlorine and low-alkali composite cement grinding aid, in parts by weight, includes: 2 parts of hydroxypropyl methylcellulose, 0.2 parts of sodium chloride, 2 parts of sodium hexametaphosphate, 2 parts of magnesium dihydrogen phosphate, and 2 parts of ammonium sulfate 0.8 parts of sodium thiosulfate, 2 parts of sodium formate, 2 parts of sodium acetate, 2 parts of aluminum sulfate, 0.8 parts of sodium thiocyanate, 2 parts of sodium metasilicate pentahydrate, 2 parts of sodium lignosulfonate, 2 parts of molasses , 2 parts of calcium lignosulfonate, 2 parts of triisopropanolamine, 2 parts of glycerol, 1.2 parts of pentaerythritol, 5 parts of p-aminobenzenesulfonic acid, 2 parts of methacrylic acid, 2 parts of maleic anhydride, polysorbate 0.8 parts, 0.8 parts of activated silica, 4 parts of diatomaceous earth, 2 parts of polytetrafluoroethylene powder, 5 parts of fly ash and 70 parts of water.

[0017] The above-mentioned low-chlorine and low-alkali composite cement g...

Embodiment 2

[0025] Low-chlorine and low-alkali composite cement grinding aid, in parts by weight, includes: 6 parts of hydroxypropyl methylcellulose, 0.6 parts of sodium chloride, 4 parts of sodium hexametaphosphate, 4 parts of magnesium dihydrogen phosphate, and 4 parts of ammonium sulfate 1.8 parts of sodium thiosulfate, 4 parts of sodium formate, 4 parts of sodium acetate, 4 parts of aluminum sulfate, 1.8 parts of sodium thiocyanate, 4 parts of sodium metasilicate pentahydrate, 6 parts of sodium lignosulfonate, 4 parts of molasses , 4 parts of calcium lignosulfonate, 6 parts of triisopropanolamine, 4 parts of glycerol, 1.8 parts of pentaerythritol, 7 parts of p-aminobenzenesulfonic acid, 4 parts of methacrylic acid, 4 parts of maleic anhydride, polysorbate 1.2 parts, 1.8 parts of activated silica, 8 parts of diatomaceous earth, 4 parts of polytetrafluoroethylene powder, 12 parts of fly ash and 120 parts of water.

[0026] The above-mentioned low-chlorine and low-alkali composite cement...

Embodiment 3

[0034] Low-chloride and low-alkali composite cement grinding aid, in parts by weight, includes: 4 parts of hydroxypropyl methylcellulose, 0.4 parts of sodium chloride, 3 parts of sodium hexametaphosphate, 3 parts of magnesium dihydrogen phosphate, and 3 parts of ammonium sulfate 1.2 parts of sodium thiosulfate, 3 parts of sodium formate, 3 parts of sodium acetate, 3 parts of aluminum sulfate, 1.2 parts of sodium thiocyanate, 3 parts of sodium metasilicate pentahydrate, 5 parts of sodium lignosulfonate, 3 parts of molasses , 3 parts of calcium lignosulfonate, 5 parts of triisopropanolamine, 3 parts of glycerol, 1.5 parts of pentaerythritol, 6 parts of p-aminobenzenesulfonic acid, 3 parts of methacrylic acid, 3 parts of maleic anhydride, polysorbate 1.0 parts, 1.2 parts of activated silica, 6 parts of diatomaceous earth, 3 parts of polytetrafluoroethylene powder, 9 parts of fly ash and 100 parts of water.

[0035] The above-mentioned low-chlorine and low-alkali composite cement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com