High-temperature-resistant insulating composition, insulating coating, and preparation method and application of insulating coating

An insulating coating and composition technology, applied in the field of coating composition preparation, can solve the problems of not affecting the insulating coating, the high temperature resistance of the insulating coating needs to be further improved, and achieve the effect of excellent adhesion performance and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

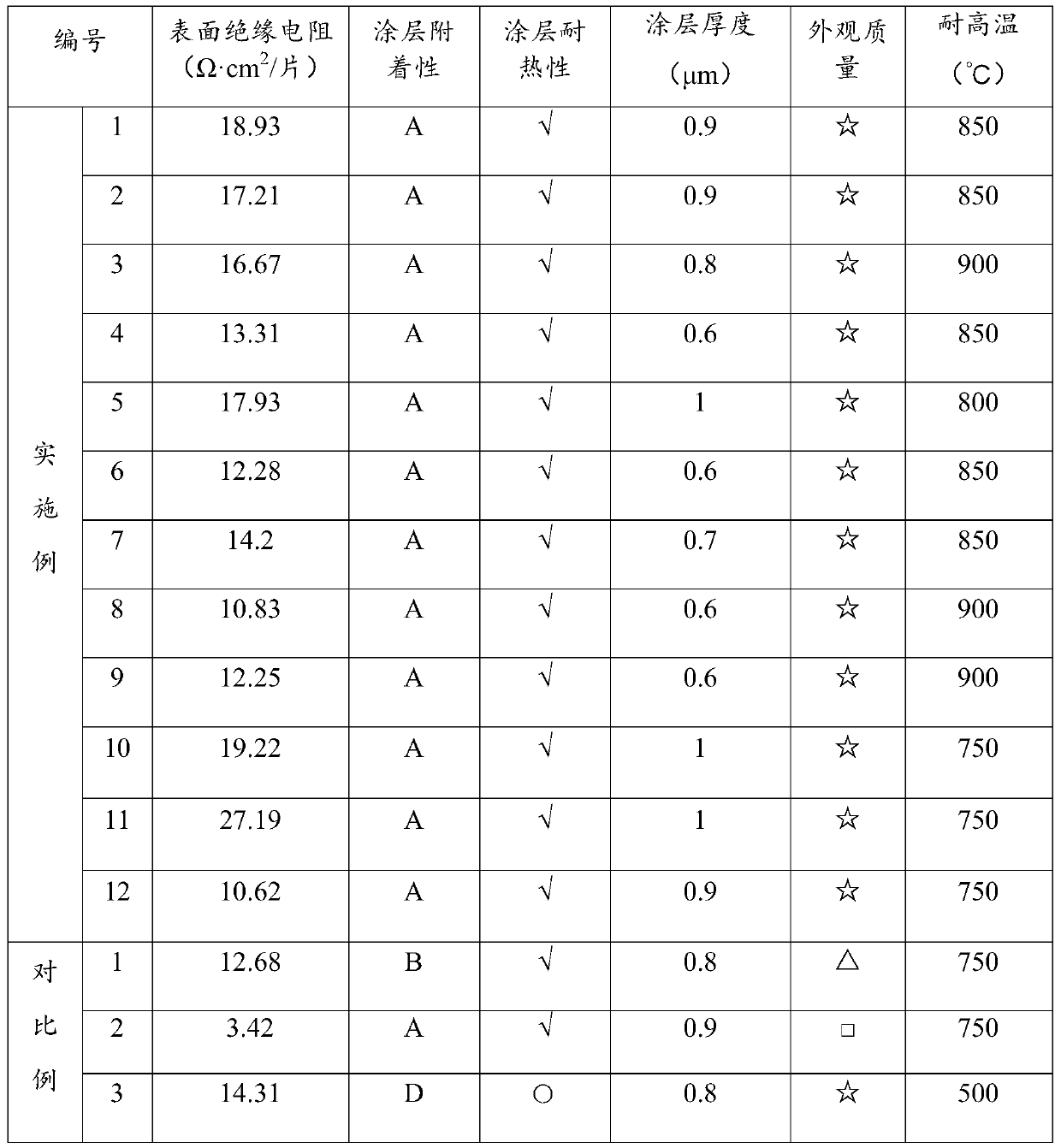

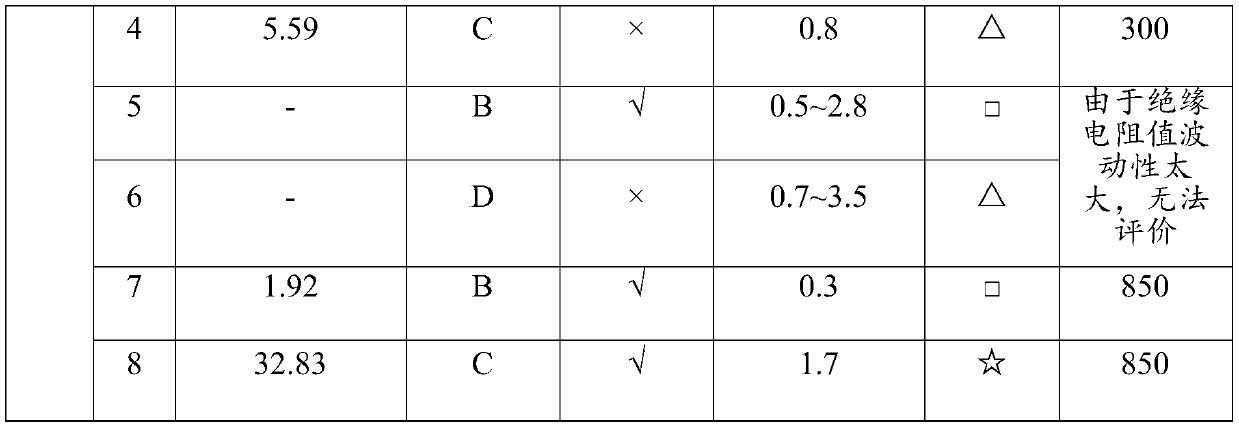

Examples

Embodiment 1

[0059] This embodiment provides an insulating composition, and its raw materials are composed of: 2.8 kg of magnesium dihydrogen phosphate, 4.5 kg of silica sol, 0.5 kg of chromic anhydride, 22 g of cyanoacetoxyethyl methacrylate, ethylene bis(oxyethylene base) bis[3-(tert-butyl-4-hydroxy-m-tolyl)propionate] 10g, butyloctyldiphenylamine 5g, fluorine-modified acrylic acid 8g, polyether-modified polysiloxane 3g, Ionized water 2.15kg; Wherein, magnesium dihydrogen phosphate is obtained by reacting phosphoric acid of 25wt% and magnesium oxide of 11wt% in deionized water by initial concentration;

[0060] This embodiment also provides an insulating coating prepared from the above insulating composition;

[0061] The above-mentioned insulating coating is prepared by the following method. Add silica sol, magnesium dihydrogen phosphate, and chromic anhydride to deionized water in sequence, and stir for 1 hour with an electric mixer; continue to add cyanoacetoxyethyl methacrylate, ethy...

Embodiment 2

[0065] This embodiment provides an insulating composition, and its raw material composition is: 2.5kg of magnesium dihydrogen phosphate, 4.4kg of silica sol, 0.6kg of chromic anhydride, 15g of methylol diacetone acrylamide, 10g of water-based alkyd resin emulsion, bis [3-(3,5-di-tert-butyl-4-hydroxy)phenyl] triethylene glycol propionate 16g, phosphate-modified acrylic acid 4g, polyether-modified polysiloxane 3g, deionized water 2.45kg Wherein, magnesium dihydrogen phosphate is obtained by reacting phosphoric acid with an initial concentration of 25wt% and magnesium oxide of 11wt% in deionized water.

[0066] This embodiment also provides an insulating coating prepared from the above insulating composition;

[0067] The above-mentioned insulating coating is prepared by the following method: add silica sol, magnesium dihydrogen phosphate, and chromic anhydride to deionized water in sequence, and stir for 1 hour with an electric mixer; continue to add methylol diacetone acrylamid...

Embodiment 3

[0071] This embodiment provides an insulating composition, and its raw materials are composed of: 3.2kg of magnesium dihydrogen phosphate, 4.7kg of silica sol, 0.4kg of chromic anhydride, 28g of cyanoacetoxyethyl methacrylate, ethylene bis(oxyethylene base) bis[3-(tert-butyl-4-hydroxy-m-tolyl)propionate 20g, fluorine-modified acrylic acid 12g, dimethylsiloxane 1.5g, tributyl phosphate 1.5g, deionized water 1.64 kg; Wherein, magnesium dihydrogen phosphate is obtained by reacting phosphoric acid of 23wt% and magnesium oxide of 8wt% in deionized water by initial concentration;

[0072] This embodiment also provides an insulating coating prepared from the above insulating composition;

[0073] The above-mentioned insulating coating is prepared by the following method. Add silica sol, magnesium dihydrogen phosphate, and chromic anhydride to deionized water in sequence, and stir for 1 hour with an electric mixer; continue to add cyanoacetoxyethyl methacrylate, ethylene Bis(oxyethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com