Method for producing feed-grade calcium dihydrogen phosphate from wet-process phosphoric acid

A technology of calcium dihydrogen phosphate and wet-process phosphoric acid, which is applied in animal feed, animal feed, chemical instruments and methods, etc., can solve the problems of increasing the production cost of calcium dihydrogen phosphate, fine product crystals, and low phosphorus yield, and achieves Small loss of phosphorus, reduction of harmful impurities, and good product fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

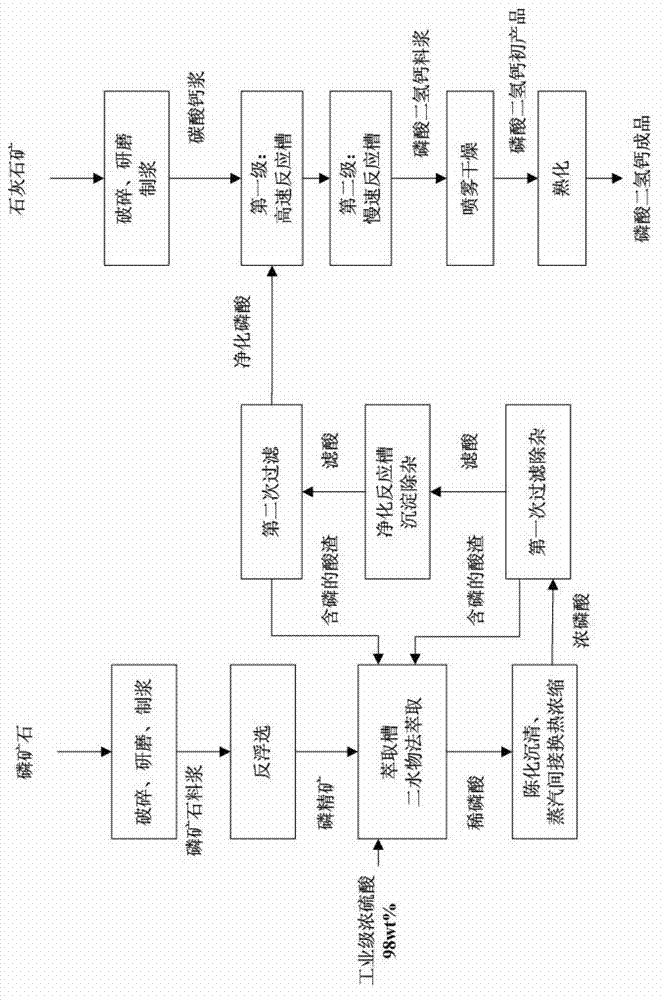

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific examples of the present invention, further illustrate the specific implementation of the technical method of adopting wet-process phosphoric acid to produce feed grade calcium dihydrogen phosphate of the present invention. The advantages of the present invention will become clearer and easier to understand through the description of specific embodiments.

[0029] Grade P 2 o 5 Content≥24wt%, MgO≤5.0wt%, Fe 2 o 3 +Al 2 o 3 ≤3.5wt% natural phosphate rock, crushed and ground into a slurry, reverse flotation to remove some impurities to obtain phosphate concentrate. For example, in reverse flotation, add K salt and Na salt as collector at 580-630 g / t ore, preferably add K salt and Na salt at 600 g / t ore to obtain P 2 o 5 Content≥30wt%, MgO≤0.5wt%, Fe 2 o 3 +Al 2 o 3 ≤1.5wt% phosphorous concentrate. These K salts and Na salts are only flotation reagents. After flotation, the action of the reagents ends, and they have no effect o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com