Bone repairing biological ceramic material based on 3D printing and preparation method thereof

A bioceramic material, 3D printing technology, applied in the field of biomedical materials, can solve problems such as difficulty in mass construction, and achieve the effect of improving biocompatibility and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

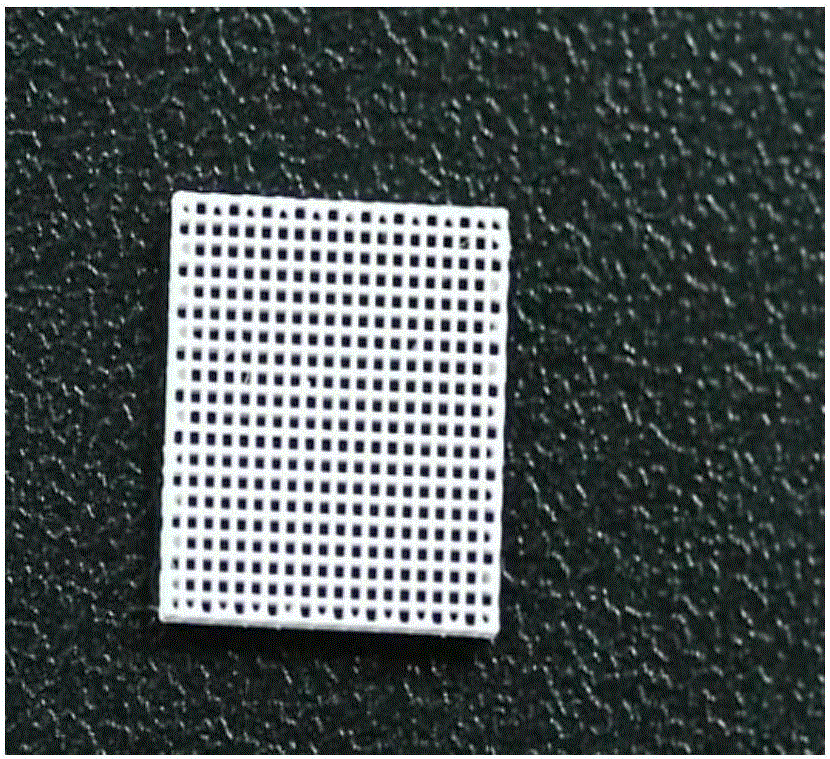

Image

Examples

Embodiment 1

[0025] Take 1.26g PLA, put it into a beaker, add a stirrer, inhale CHCl3 (analytical pure, Hengyang Kaixin Chemical Reagent Co., Ltd.) with a plastic dropper, dropwise add it to the beaker, drop 7.13g to stop, and use a parafilm Seal the mouth of the beaker, then place it on a stirrer and stir until the PLA is completely dissolved, and adjust the rotation speed so that the solution has no bubbles, and prepare a 15wt% transparent solution A. Then weigh 1.47g β-TCP and nano-HA respectively, add them to solution A, stir for 1h until uniform and stable, and obtain slurry B, fill slurry B into the pre-prepared needle tube (EFD), and seal it with parafilm The rear end and the front end of the needle tube were left to age for 24 hours to obtain slurry C. The high-precision air-floating automatic three-dimensional motion platform ABL10150 (Aerotech, U.S.A.) with pre-adjusted three-dimensional fine direct writing movement, the control intelligent extrusion system EFDUltraTM2400, the wo...

Embodiment 2

[0029] Take 1.43g PLA, put it into a beaker, add a stirring bar, inhale CHCl3 drop by drop into the beaker with a rubber dropper, stop dropping 8.10g, seal the mouth of the beaker with a parafilm, and then put it on the stirrer Stir until the PLA is completely dissolved, and adjust the rotation speed so that the solution has no bubbles, and prepare a 15wt% transparent solution A. Then weigh 2.86g of β-TCP and nano-HA respectively, add them to solution A, stir for 1h until uniform and stable, and obtain slurry B, fill slurry B into a pre-prepared needle tube (EFD), and seal it with a parafilm The rear end and the front end of the needle tube were left to age for 24 hours to obtain slurry C. The high-precision air-floating automatic three-dimensional motion platform ABL10150 (Aerotech, U.S.A.) with pre-adjusted three-dimensional fine direct writing movement, the control intelligent extrusion system EFDUltraTM2400, the working input air pressure is 480KPa-580KPa, and the air pres...

Embodiment 3

[0033] Take 1g PLA, put it into a beaker, add a stirring bar, and suck CHCl with a plastic dropper 3 Add drop by drop into the beaker, stop dropping 9g, seal the mouth of the beaker with a parafilm, then put it on the stirrer and stir until the PLA is completely dissolved, and adjust the speed so that the solution has no bubbles, and prepare a 10wt% transparent Solution A. Then weigh 4.5g of β-TCP and nano-HA respectively, add them to solution A, stir for 1h until uniform and stable, and obtain slurry B, fill slurry B into the pre-prepared needle tube (EFD), and seal it with parafilm The rear end and the front end of the needle tube were left to age for 24 hours to obtain slurry C. The high-precision air-floating automatic three-dimensional motion platform ABL10150 (Aerotech, U.S.A.) with pre-adjusted three-dimensional fine direct writing movement, the control intelligent extrusion system EFDUltraTM2400, the working input air pressure is 480KPa-580KPa, and the air pressure af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com