Narrow pore size distribution aluminum titanate body and method for making same

a technology of aluminum titanate and pore microstructure, which is applied in the field of narrow pore size distribution of aluminum titanate ceramic bodies, can solve the problems of relatively high cost of silicon carbide, inability to obtain well-interconnected pore microstructures, and inability to meet the requirements of high temperature operation, and achieve high degree of interconnected porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

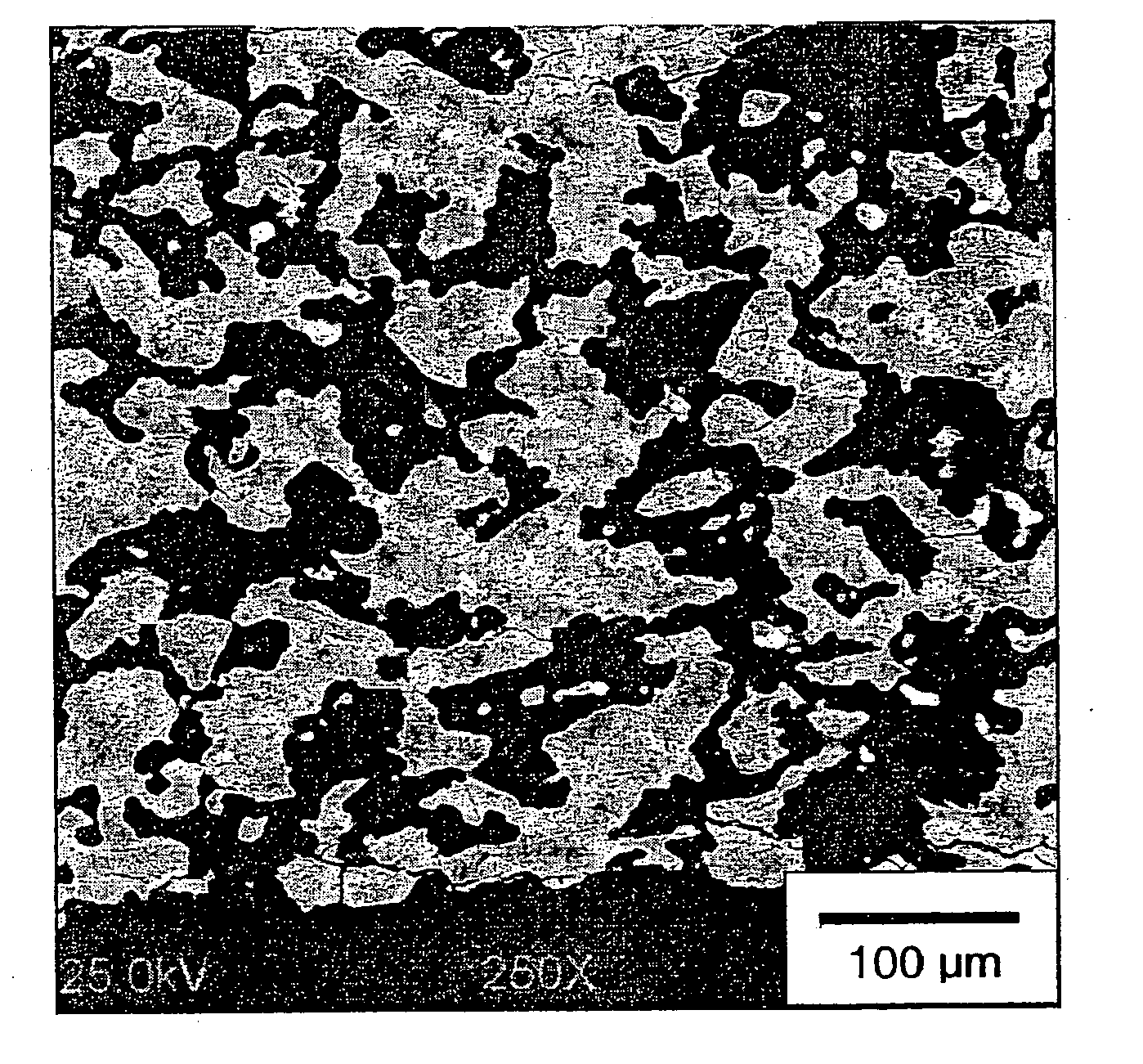

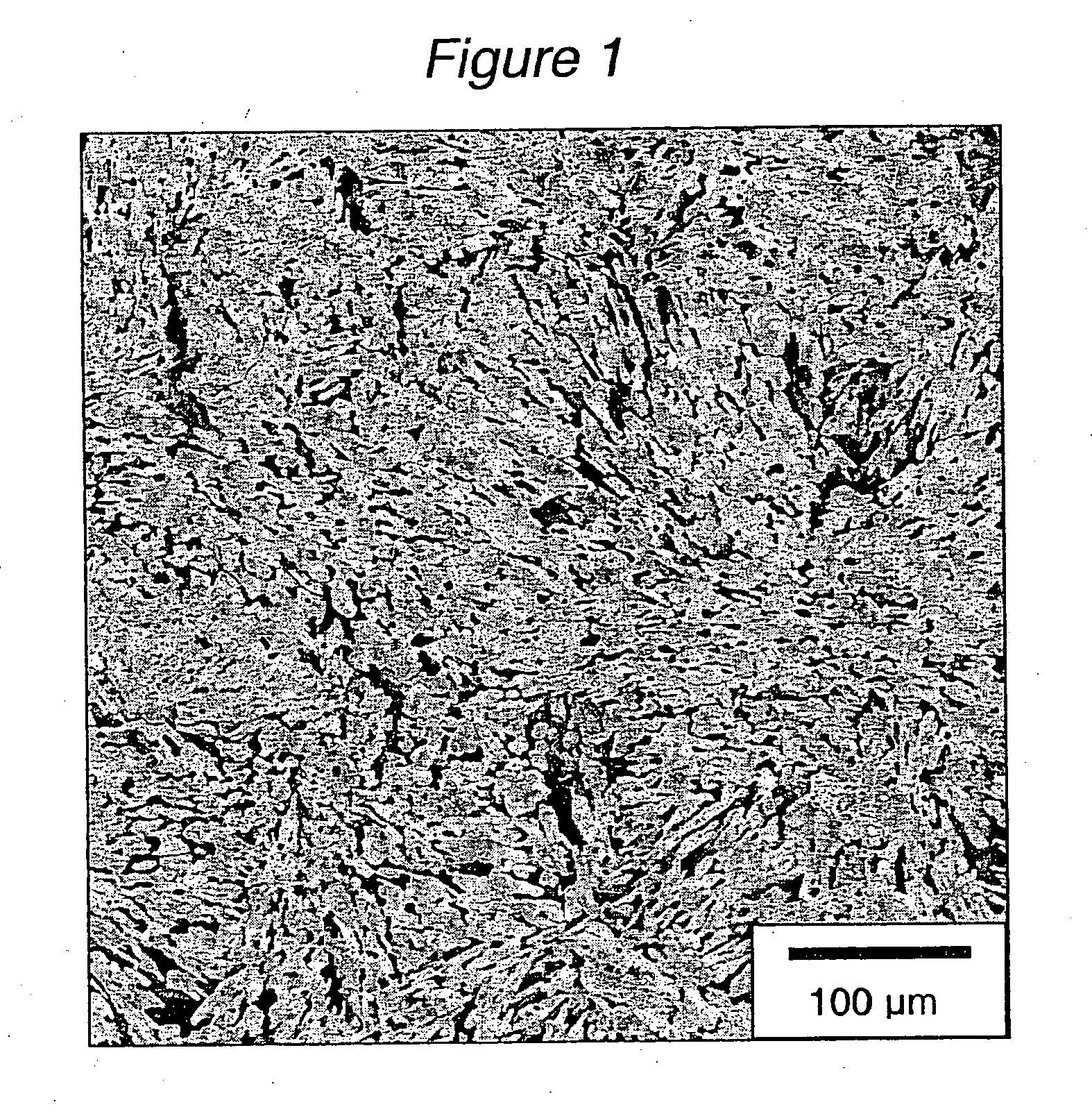

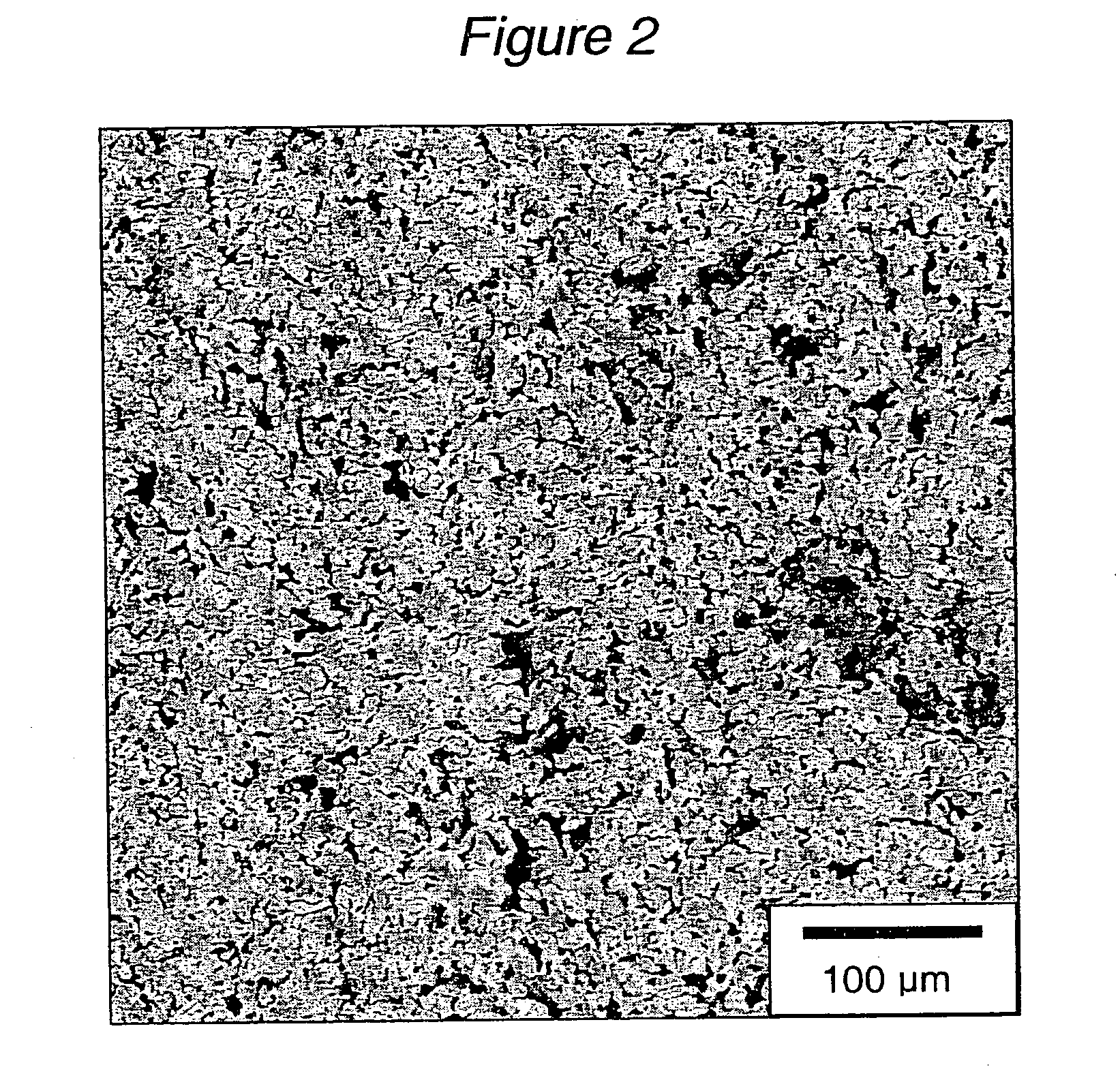

Image

Examples

examples

[0037] The invention is further illustrated with the following non-limiting examples. Inventive and comparative samples are prepared by admixing the inorganic raw materials, metal oxide additives, and pore-forming agents with 4 to 6 wt % methyl cellulose binder, 0.15 wt % triethanol amine, 1% tall oil, and 14 to 18 wt % water. The mixture is plasticized in a stainless steel muller and extruded as 5 / 16-inch diameter rod and 1-inch, 2-inch, or 5.7-inch diameter honeycomb. Parts are dried and then fired in a gas or electric kiln at 14000 to 1500° C. and held for 4 to 10 hours.

[0038] After firing, the porosities of the samples are characterized by mercury porosimetry, the CTEs measured by dilatometry, and the modulus of rupture (MOR) by the four-point method on 5 / 16-in diameter rods. MOR values are reported in pounds per square inch (psi). Some samples are also crushed and their crystalline phases identified by powder x-ray diffractometry. Pore diameters (d10, d50 and d90) are in micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| median pore diameter | aaaaa | aaaaa |

| median pore diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com