Lapping sheet and its manufacturing method and polishing device

A manufacturing method and technology of abrasive sheets, which are used in grinding devices, manufacturing tools, grinding machine tools, etc., can solve the problems of poor fluidity of grinding fluid, difficulty in uniform grinding pad batches, and poor chip evacuation, and achieve good fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

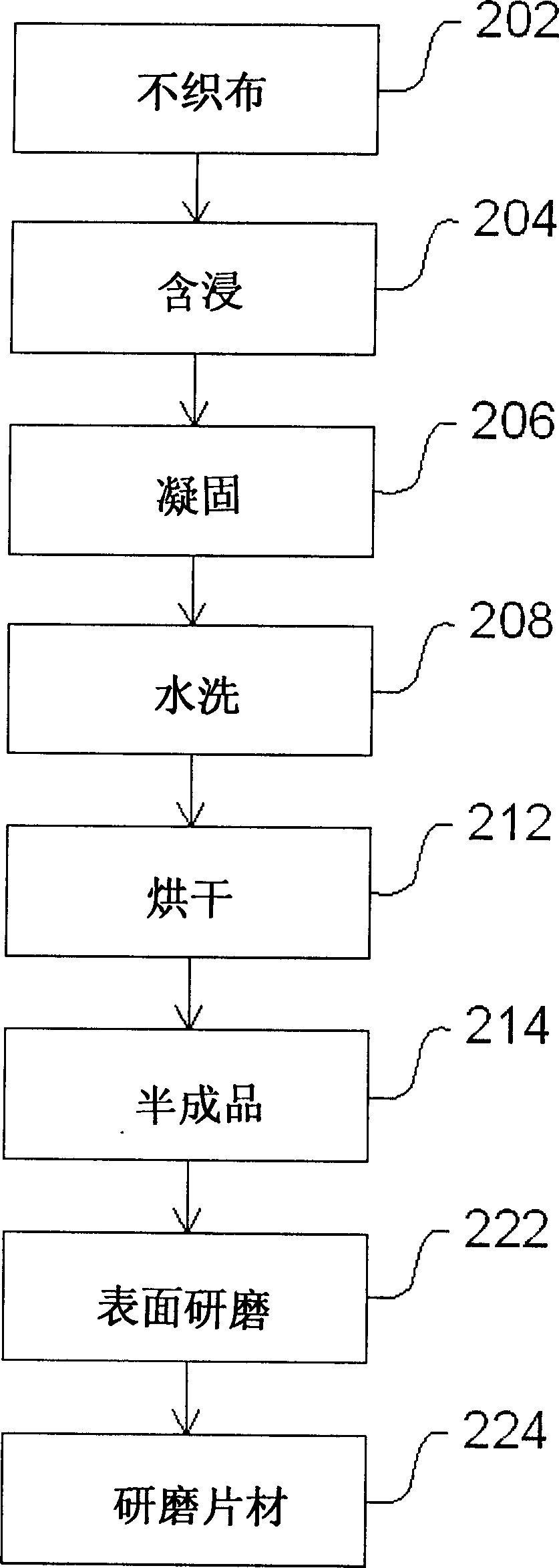

[0022] refer to figure 1 , according to the method for manufacturing an abrasive sheet according to an embodiment of the present invention, first provide a non-woven fabric with fibers (step 202), and impregnate the non-woven fabric with a polymer elastomer resin solution to form an impregnated layer in the non-woven fabric (step 204 ), and then the impregnated layer is solidified (step 206), washed (step 208) and dried (step 212) to form a semi-finished abrasive sheet (step 214). The abrasive sheet semi-finished product includes the non-woven fabric and the polymer elastic body with interconnected porosity, wherein the polymer elastic body has interconnected holes and is solidified and combined in the non-woven fabric. Those with ordinary knowledge in the technical field of the present invention know that if the aperture of the communicating hole of the polymeric elastomer is too large, the abrasive particles will gather in the communicating hole during the polishing process;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com