Preparation of white light emitting diode using a phosphor

A technology of white light emitting and diode, applied in the direction of luminescent materials, electroluminescence light source, gas discharge lamp, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

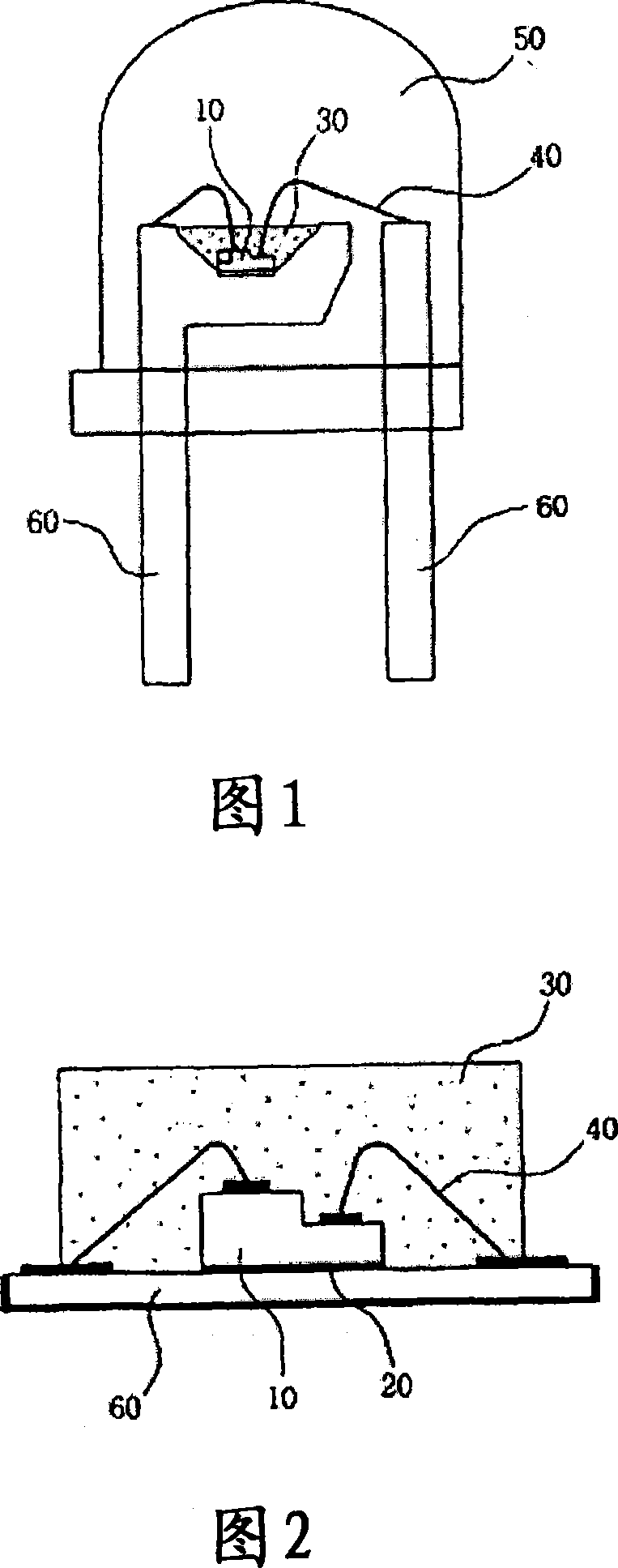

[0050] Example 1: Preparation of white light-emitting diodes using red, green, and blue phosphors

[0051] The UV LED chip is mounted on the base of the package substrate or on the lead frame with Ag paste. Next, the red, blue and green three-color phosphorescent material mixture is directly or indirectly coated on the UV LED chip, so that the purple light emitted by the UV LED chip is transmitted through the three-color phosphorescent material mixture.

[0052] That is, each of the red, blue, and green phosphorescent mixtures given in Tables 1 to 3 below was coated on the UV LED chip so that the 405nm purple light emitted by the UV LED chip was transmitted through the three-color phosphorescent material mixture.

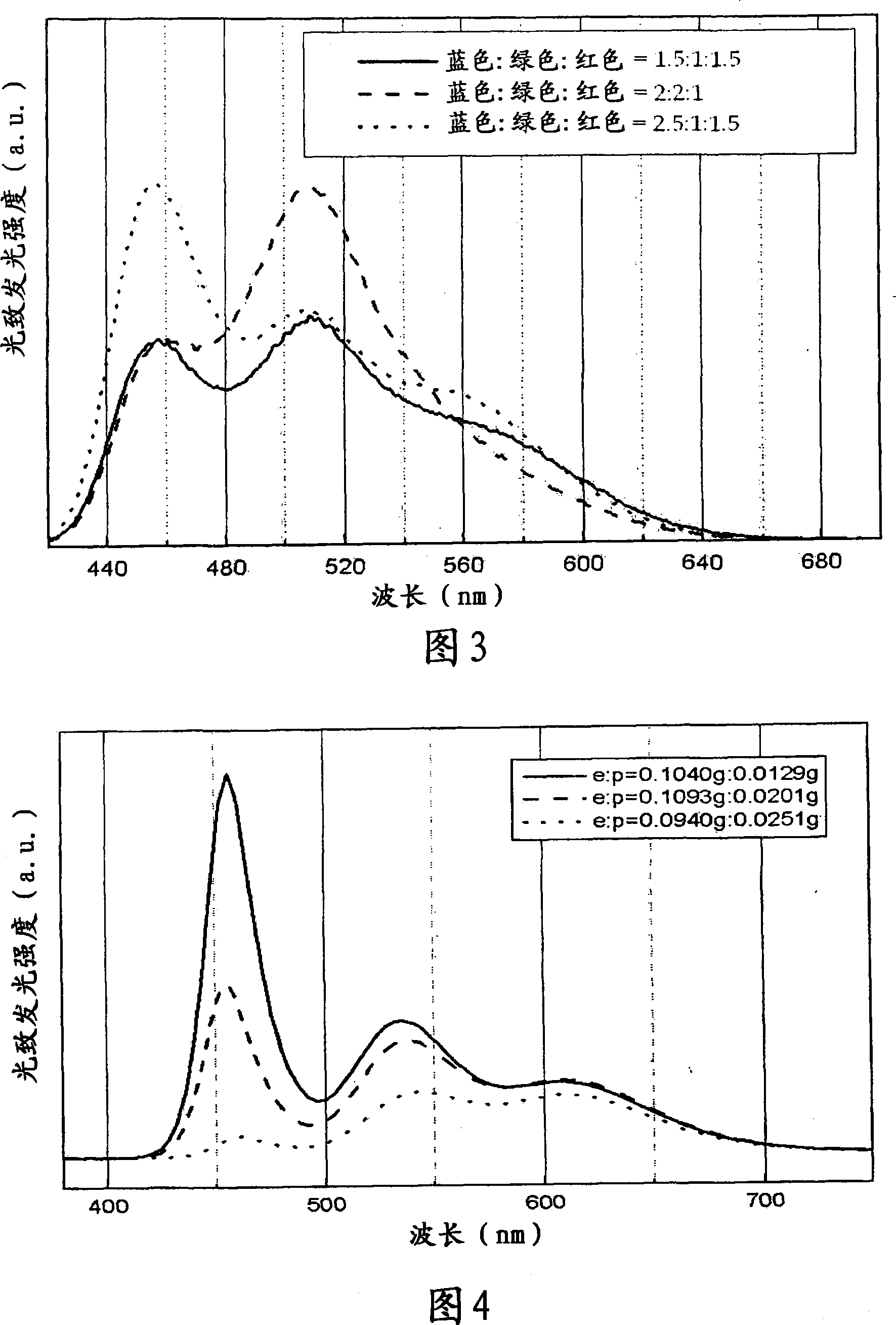

[0053] As shown in the color coordinates given in Tables 1 to 3 and the photoluminescence spectrum given in FIG. 3 , the generation of white light was confirmed.

[0054] Table 1

[0055]

red phosphorescent

green phosphorescent

...

example 2

[0060] Example 2: Preparation of white light-emitting diodes using a mixture of red and green phosphors

[0061] Mount the blue LED chip on the base or lead frame of the packaging substrate with Ag paste. Next, the red and green two-color phosphorescent material mixture is directly or indirectly coated on the blue LED chip, so that the blue light emitted by the blue LED chip is transmitted through the two-color phosphorescent material mixture.

[0062] That is, each of the red, blue, and green phosphorescent mixtures given in Table 4 below is coated on the blue LED chip, so that the 465nm blue light emitted by the blue LED chip is transmitted through the two-color phosphorescent material mixture.

[0063] As shown in the color coordinates given in Table 4 and the photoluminescence spectrum given in Figure 4, the generation of white light was confirmed.

[0064] Table 4

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com