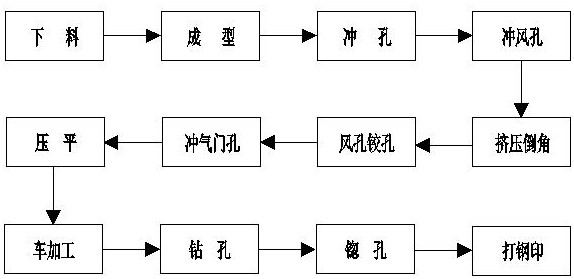

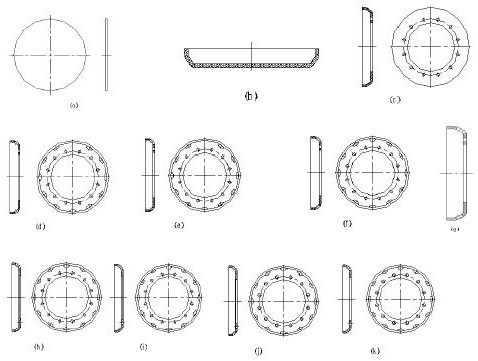

Production process of spokes for engineering machinery wheels

A technology of construction machinery and production process, applied in the direction of vehicle parts, transportation and packaging, can solve the problems of unstable spoke quality control, low production process control accuracy, affecting the service life of wheels, etc., and achieves high processing efficiency and remarkable hole structure. The effect of social and economic benefits, high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Cutting: cutting and blanking Q345B alloy steel plate of equal thickness with a thickness of 14mm, using plasma cutting, cutting the plate into a disc shape, and the verticality of the end face after cutting is 90°±0.5°;

[0064] (2) Forming: Install the spoke forming mold on the hydraulic press, adjust the stroke, and then place the cut disc on the forming mold to form a spoke blank with a radian;

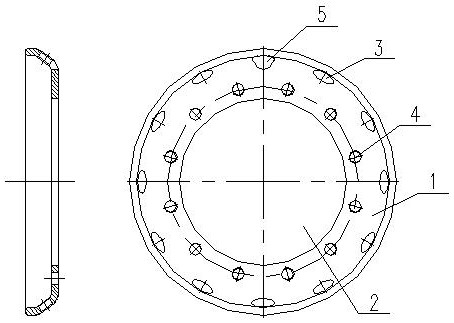

[0065] (3) Punching: Install the spoke punching die on the hydraulic press, adjust the die and punching stroke, put the formed spoke blank into the spoke punching die for punching, punch the center hole 2 and the bolt hole 4 and the outer The concentricity of the diameter is ≤∅0.5mm, and the spoke blanks punched by the center hole and the bolt hole are obtained;

[0066] (4) Blowing hole: Install the spoke blowing hole mold on the punching machine, adjust the stamping stroke of the mold, place the spoke blank punched in the center hole 2 and bolt hole 4 in the spoke blo...

Embodiment 2

[0076] (1) Cutting: cutting and cutting Q345B alloy steel plate with equal thickness of 16mm, using plasma cutting, cutting the plate into a disc shape, and the verticality of the end face after cutting is 90°±0.5°;

[0077] (2) Forming: Install the spoke forming mold on the hydraulic press, adjust the stroke, and then place the cut disc on the forming mold to form a spoke blank with a radian;

[0078] (3) Punching: Install the spoke punching die on the hydraulic press, adjust the die and punching stroke, put the formed spoke blank into the spoke punching die for punching, punch the center hole 2 and the bolt hole 4 and the outer The concentricity of the diameter is ≤∅0.5mm, and the spoke blanks punched by the center hole and the bolt hole are obtained;

[0079] (4) Blowing hole: Install the spoke blowing hole mold on the punching machine, adjust the stamping stroke of the mold, place the spoke blank punched in the center hole 2 and bolt hole 4 in the spoke blowing hole mold, ...

Embodiment 3

[0089] (1) Cutting: cutting and blanking Q345B alloy steel plate of equal thickness with a thickness of 22mm, using laser cutting, cutting the plate into a disc shape, and the verticality of the end face after cutting is 90°±0.5°;

[0090] (2) Forming: Install the spoke forming mold on the hydraulic press, adjust the stroke, and then place the cut disc on the forming mold to form a spoke blank with a radian;

[0091] (3) Punching: Install the spoke punching die on the hydraulic press, adjust the die and punching stroke, put the formed spoke blank into the spoke punching die for punching, punch the center hole 2 and the bolt hole 4 and the outer The concentricity of the diameter is ≤∅0.5mm, and the spoke blanks punched by the center hole and the bolt hole are obtained;

[0092] (4) Blowing hole: Install the spoke blowing hole mold on the punching machine, adjust the stamping stroke of the mold, place the spoke blank punched in the center hole 2 and bolt hole 4 in the spoke blow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com