A kind of internal meshing gear pump capable of realizing partial axial compensation

An internal gear pump and axial compensation technology, which is applied to rotary piston type/oscillating piston type pump components, pumps, pump components, etc., can solve bottlenecks in pump internal pressure rise, glue failure, and wear and tear. Stress increase and other problems can be eliminated to eliminate concentrated stress and eccentric wear, improve compressive capacity, and reduce frictional damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

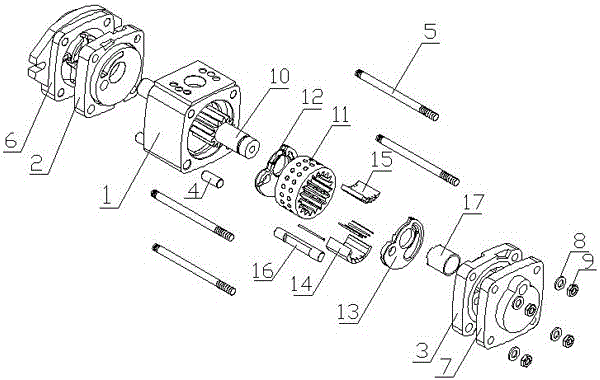

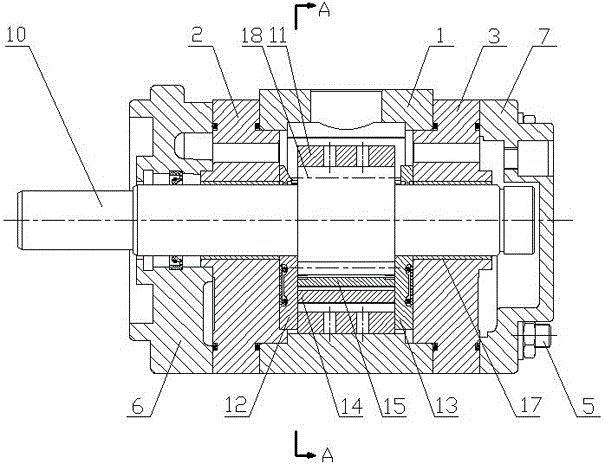

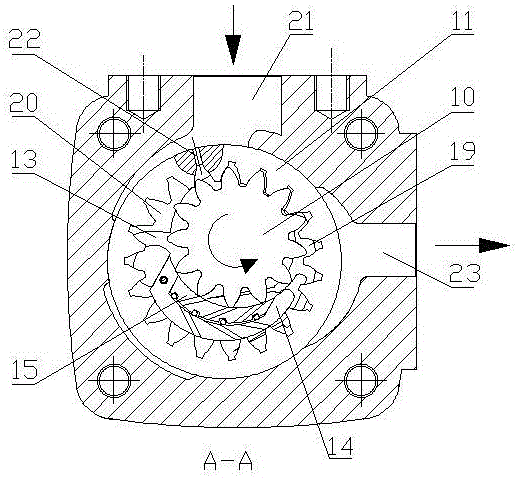

[0033] Such as Figure 1~11As shown, in this embodiment, the pump body 1, the left connecting cover 2 and the right connecting cover 3 are positioned by the positioning pin 4 in an internal meshing gear pump that can realize axial compensation of the divisions, and the left and right connecting cover 3 is positioned by the stud bolt 5. The pump cover 6, the left cover 2, the pump body 1, the right cover 3, and the right pump cover 7 are connected as a whole, which are locked by the gasket 8 and the nut 9; the internal meshing gear pump is equipped with a gear shaft 10, Inner ring gear 11, left axial compensation device 12, right axial compensation device 13, large crescent block 14, small crescent block 15, limit pin 16, sliding bearing 17; Each slide bearing 17 is placed, and its fit is a transition fit. The gear shaft 10 passes through the slide bearing 17 and its fit is also a transition fit. The gear shaft 10 and the slide bearing 17 are also a transition fit. The gear sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com