Technology for making strengthened anchor such as end cold-pressing

A processing method and technology of cold pressing head, applied to threaded products, other household appliances, household appliances, etc., can solve the problems of reducing stirring effect, large anchor rotation resistance, poor grip force of rod body, etc., to reduce material Effects of loss and strength loss, small propulsion and rotation resistance, and increased load-bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

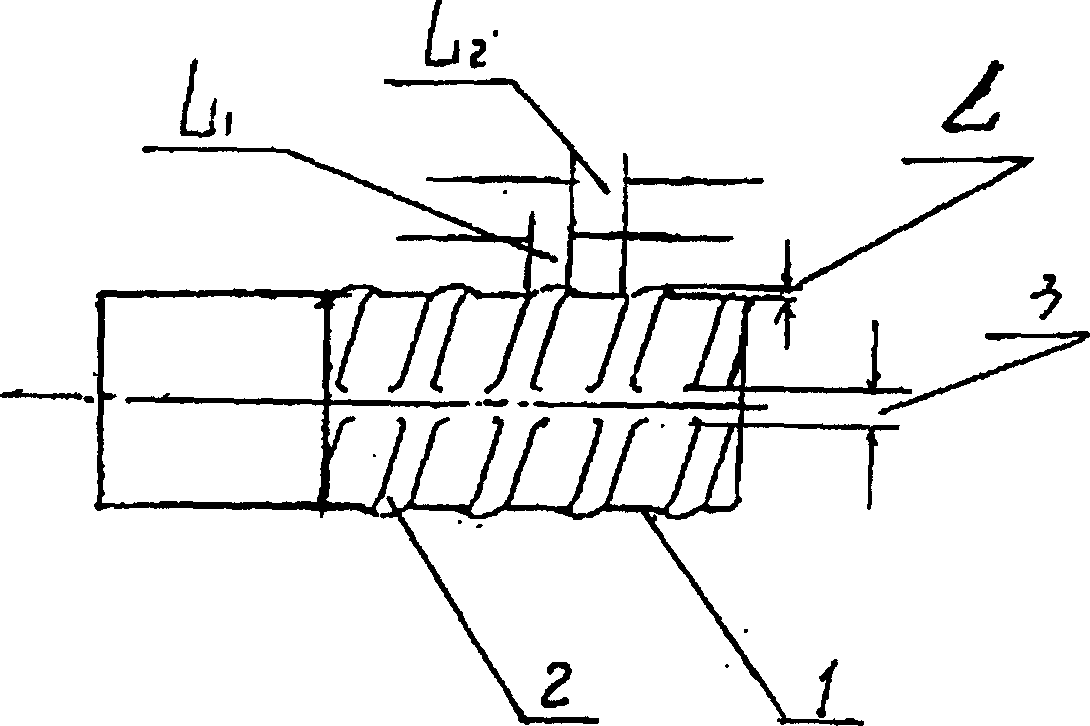

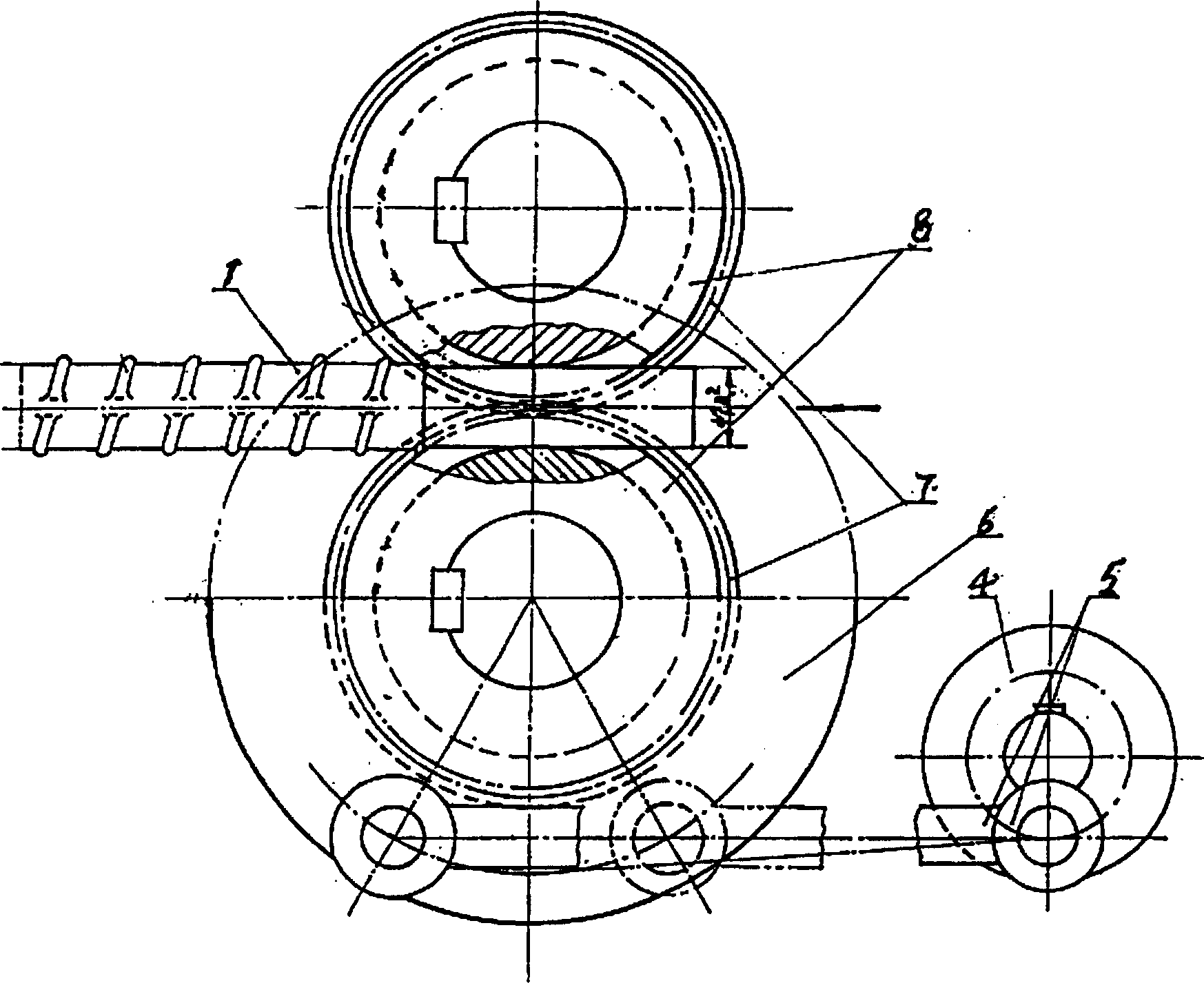

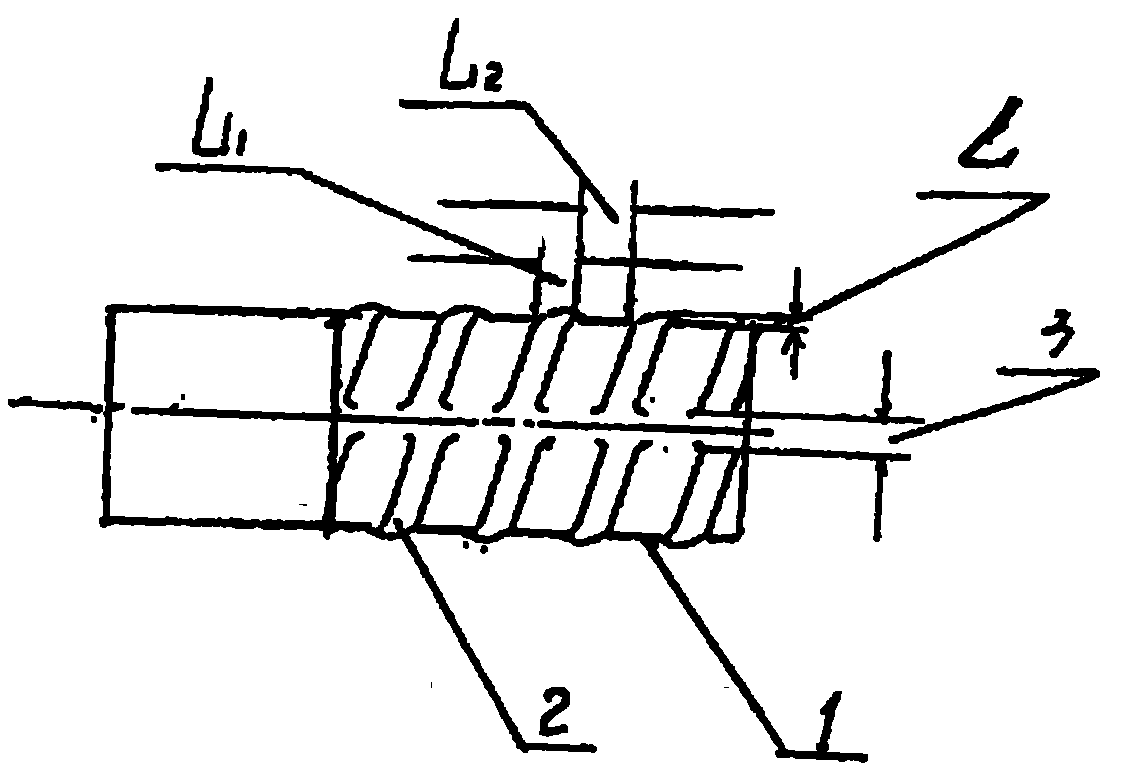

[0008] attached figure 1 It is the cold-pressed head and other strong anchor rods of the present invention. In the figure 1 is the rod body, and the axial spiral rib 2 is processed on the rod body 1, that is, the one-way left-handed anchor rod without longitudinal reinforcement. The diameter of the rod body 1 has many specifications, usually in Within the range of Φ20-Φ22 mm, for example, the diameter of the rod body 1 can be Φ21.6 mm, Φ20.6 mm, etc. When the rib 2 on the anchor body is fully helically thermally bonded along the rod body, the thermally bonded suture 3 is 1.5 mm, the diameter of the rod body 1 is Φ21.6 mm, and the pitch L 2 is 14 mm, the rib height L is 1.1 mm, and the rib width L 2 is 2.2mm. When the rib on the anchor rod body 1 is a full spiral cold rolling body along the rod body, there is no joint line, the diameter of the rod body 1 is Φ20.6 mm, the rib height is L0.8 mm, and the rib width is L 1 1.8 mm, pitch L 2 is 8mm. The diameter of the rolling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com