Method for improving weak light response of amorphous silicon film battery

A technology of amorphous silicon thin film and battery, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of interface defect density, stress concentration, etc., achieve weak light response improvement, eliminate heterojunction, and eliminate stress Effects of Concentration and Defect Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

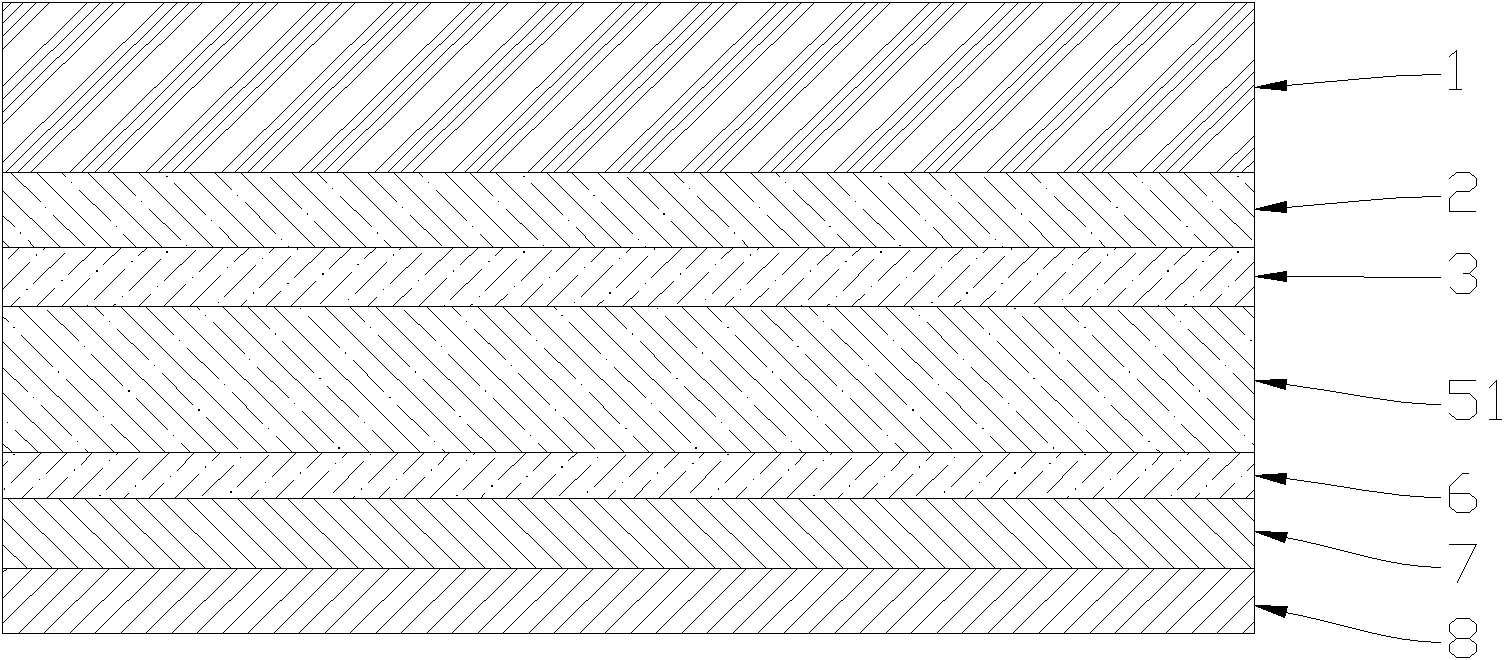

Embodiment 1

[0039] (1) Cleaning the transparent conductive oxide (TCO) substrate;

[0040] (2) On the TCO substrate, use plasma-enhanced chemical vapor deposition equipment to deposit an amorphous silicon film. Wherein the P layer deposition parameters are as follows:

[0041] Deposit the P-type layer on the transparent conductive glass, the deposition process parameters of the P layer are: SiH 4 、H 2 、CH 4 , TMB (trimethylboron or diethylalkane) gas, the deposition temperature is 180-260°C, and the deposition power density is 0.006-0.03W / cm 2 , the deposition pressure is 60-300Pa, CH 4 : SiH 4 The gas flow ratio is 40-70:100, and the deposition thickness is 10-20nm.

[0042] I layer through SiH 4 、H 2 、CH 4 gas, the deposition temperature is 180-260°C, H 2 : SiH 4 The dilution ratio is 2-20:1, and the deposition power density is 0.006-0.03W / cm 2 , the deposition pressure is 60-150Pa, CH 4 : SiH 4 The gas flow ratio is 7-10:100, and the deposition thickness is 150-500nm.

...

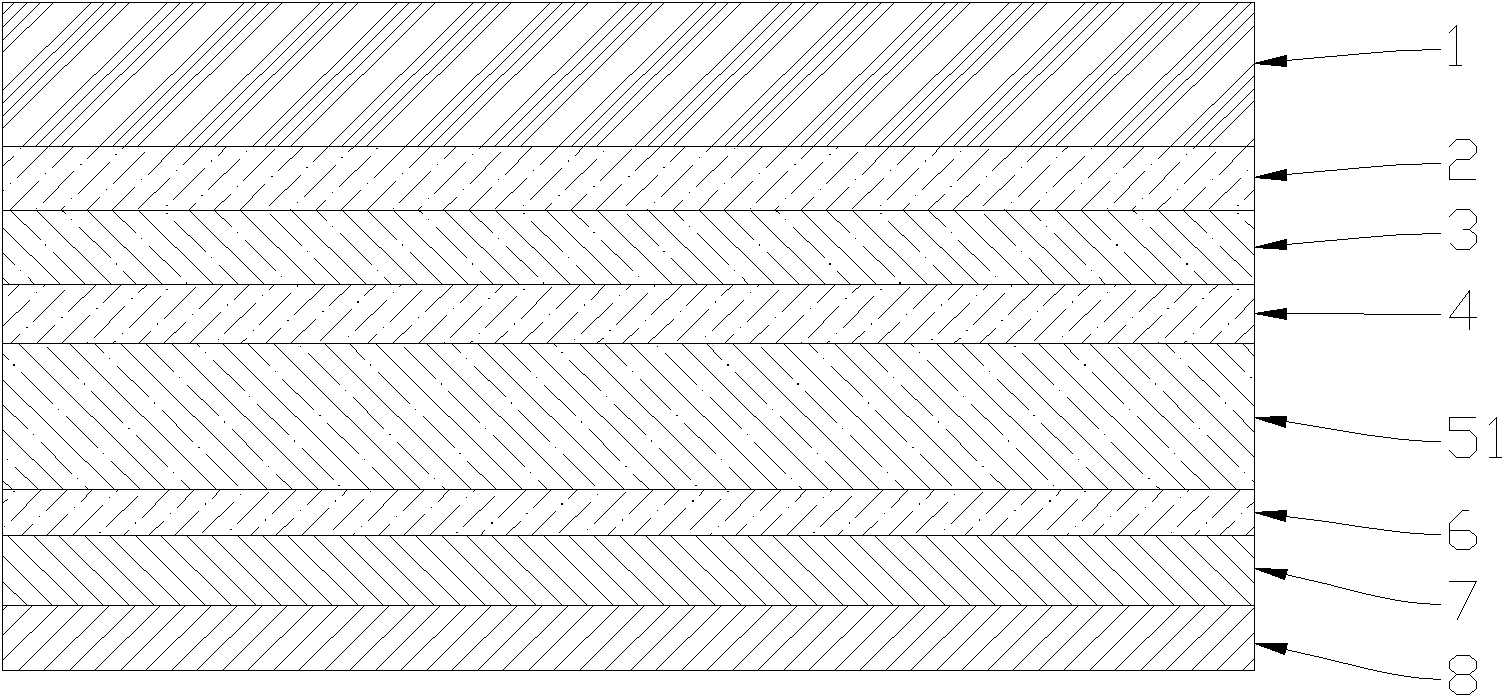

Embodiment 2

[0047] (1) Cleaning the transparent conductive oxide (TCO) substrate;

[0048] (2) On the TCO substrate, use plasma-enhanced chemical vapor deposition equipment to deposit an amorphous silicon film. Wherein the P layer deposition parameters are as follows:

[0049] Deposit the P-type layer on the transparent conductive glass, the deposition process parameters of the P layer are: SiH 4 、H 2 、CH 4 , TMB (trimethylboron or diethylalkane) gas, the deposition temperature is 180-260°C, and the deposition power density is 0.006-0.03W / cm 2 , the deposition pressure is 60-300Pa, CH 4 : SiH 4 The gas flow ratio is 40-70:100, and the deposition thickness is 10-20nm.

[0050] I layer through SiH 4 、H 2 、CH 4 gas, the deposition temperature is 180-260°C, H 2 : SiH 4 The dilution ratio is 2-20:1, and the deposition power density is 0.006-0.03W / cm 2 , the deposition pressure is 60-150Pa, CH 4 : SiH 4 The gas flow ratio is 13-20:100, and the deposition thickness is 150-500nm.

...

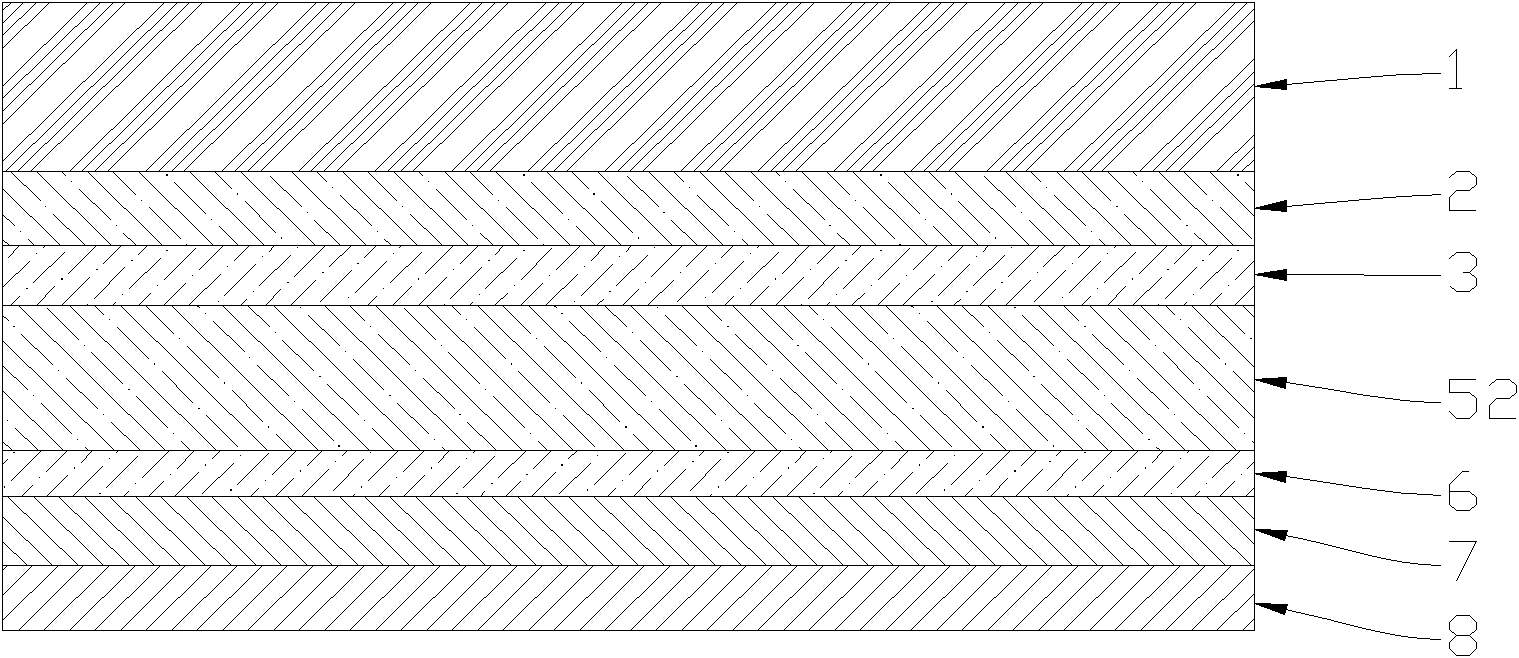

Embodiment 3

[0055] (1) Cleaning the transparent conductive oxide (TCO) substrate;

[0056] (2) On the TCO substrate, use plasma-enhanced chemical vapor deposition equipment to deposit an amorphous silicon film. Wherein the P layer deposition parameters are as follows:

[0057] Deposit the P-type layer on the transparent conductive glass, the deposition process parameters of the P layer are: SiH 4 、H 2 、CH 4 , TMB (trimethylboron or diethylalkane) gas, the deposition temperature is 180-260°C, and the deposition power density is 0.006-0.03W / cm 2 , the deposition pressure is 60-300Pa, CH 4 : SiH 4 The gas flow ratio is 40-70:100, and the deposition thickness is 10-20nm.

[0058] I layer through SiH 4 、H 2 、CH 4 gas, the deposition temperature is 180-260°C, H 2 : SiH 4 The dilution ratio is 2-20:1, and the deposition power density is 0.006-0.03W / cm 2 , the deposition pressure is 60-150Pa, CH 4 : SiH 4 The gas flow ratio is 23-33:100, and the deposition thickness is 150-500nm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com