Annular combustion increasing structure on charging outer end surface of missile engine

An engine and outer end face technology, applied in rocket engine installations, machines/engines, mechanical equipment, etc., can solve the problems of reduced engine mass ratio, increased engine risk, and reduced performance, increased initial thrust, and eliminated grain stress concentration. With cracks, the effect of avoiding the reduction of the mass ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

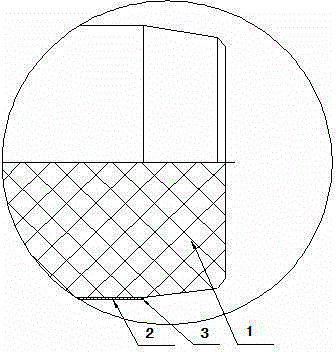

[0015] Such as figure 1 Shown is a schematic diagram of the circumferential combustion-increasing structure on the outer end face of the missile engine charge of the present invention.

[0016] The combustion-increasing structure includes 1: powder column, 2: coating sleeve, and 3: liner. The powder column and the covering sleeve are firmly bonded through the lining layer.

[0017] The powder column 1 adopts hydroxybutylated propellant, and the powder column 1 is in the shape of a solid column charged with powder. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com