Toroidal type stepless transmission and stepless transmission

A transmission unit and infinitely variable speed technology, applied in the direction of transmission, friction transmission, belt/chain/gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

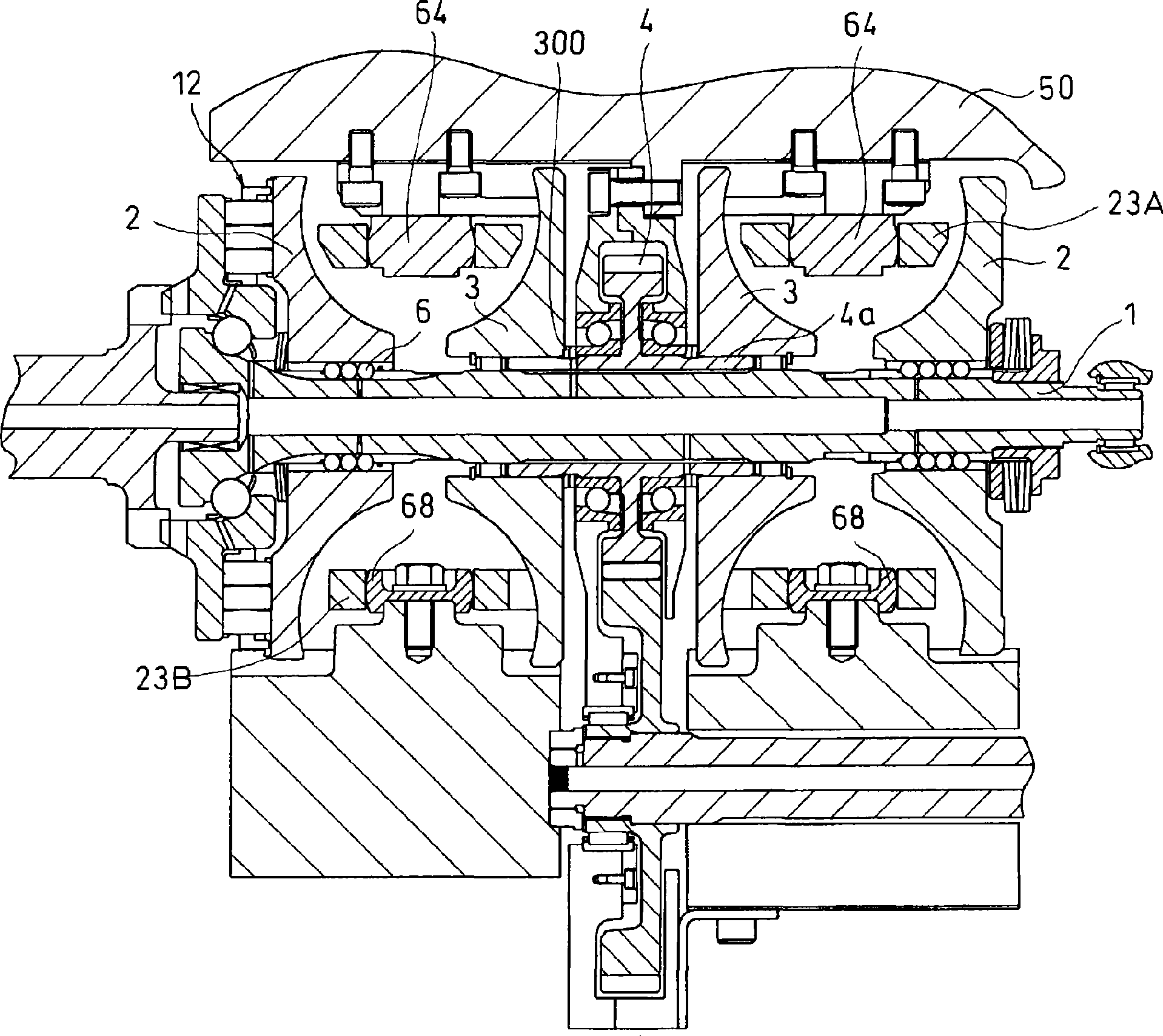

[0080] Hereinafter, embodiments of the present invention will be described with reference to the drawings. It should be noted that the present invention is characterized by the power transmission structure between the guide carrier of the planetary gear device and the disc of the annular continuously variable transmission unit, since it is otherwise structurally and functionally similar to the conventional structure already described above , Therefore, in the following description, only the characteristic parts of the present invention are described, and the other parts of the present invention are only given by giving Figure 9 to Figure 11 The same reference numerals are briefly described.

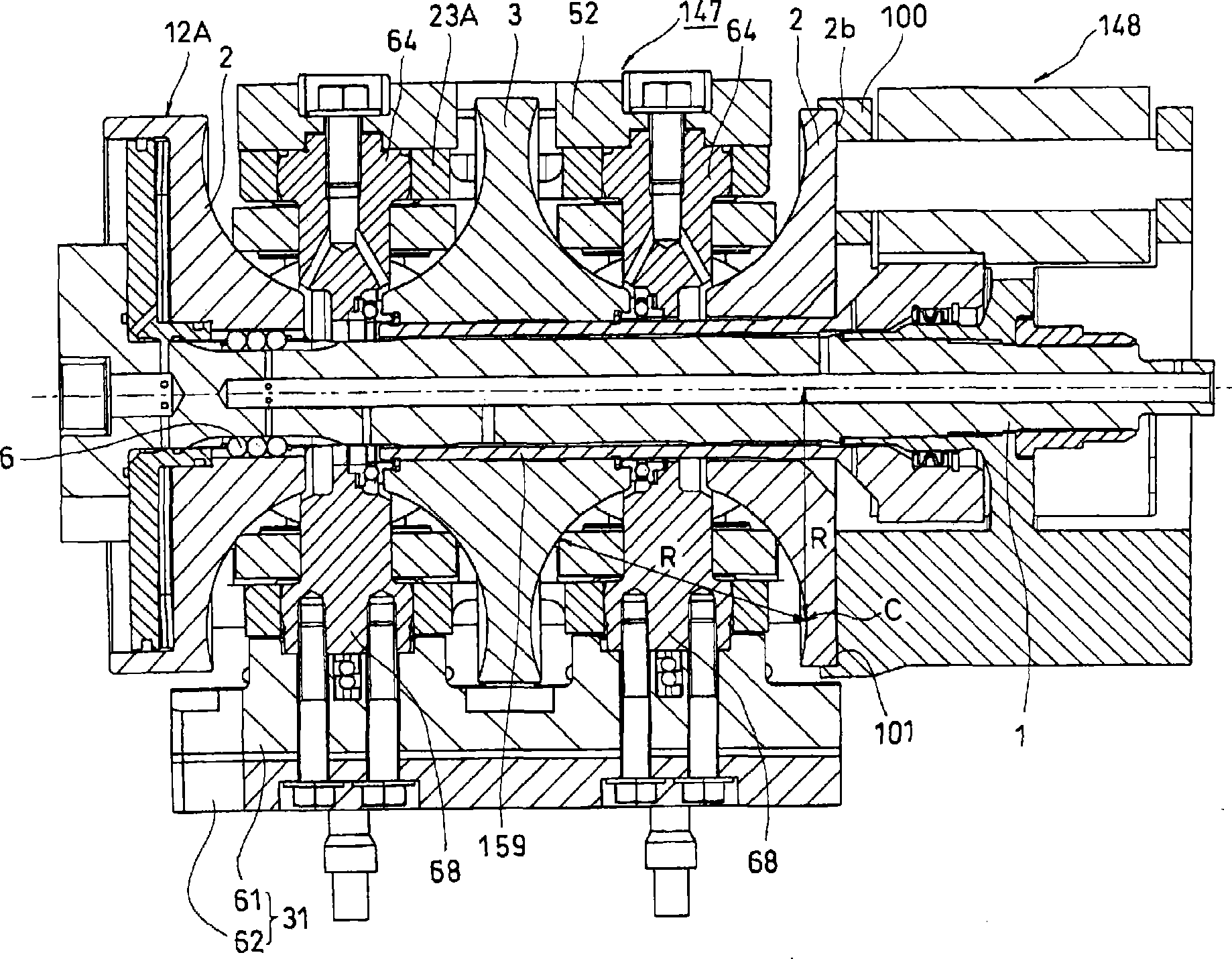

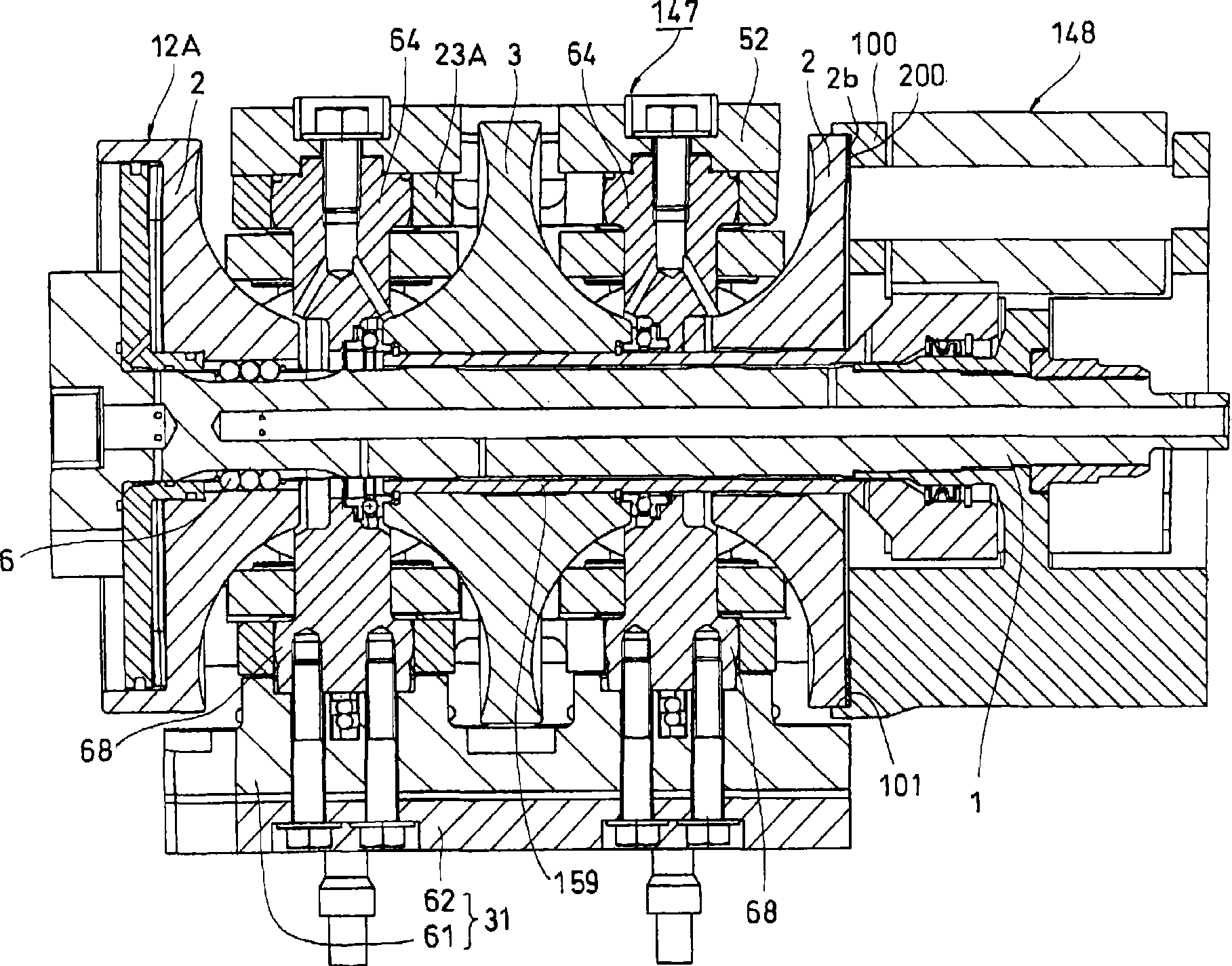

[0081] figure 1 A continuously variable transmission according to a first embodiment of the present invention is shown. As shown, in this embodiment, the input shaft 1 and the guide frame (power transmission member) 100 of the planetary gear unit 148 are integrated. The annular conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com