Metal plate sample stretching and clamping device and usage method thereof

A clamping device, metal plate technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problem of large mechanical damage at the clamping end of the sample, failure of the test, and Breakage and other problems, to achieve high accuracy, eliminate mechanical damage, and improve the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

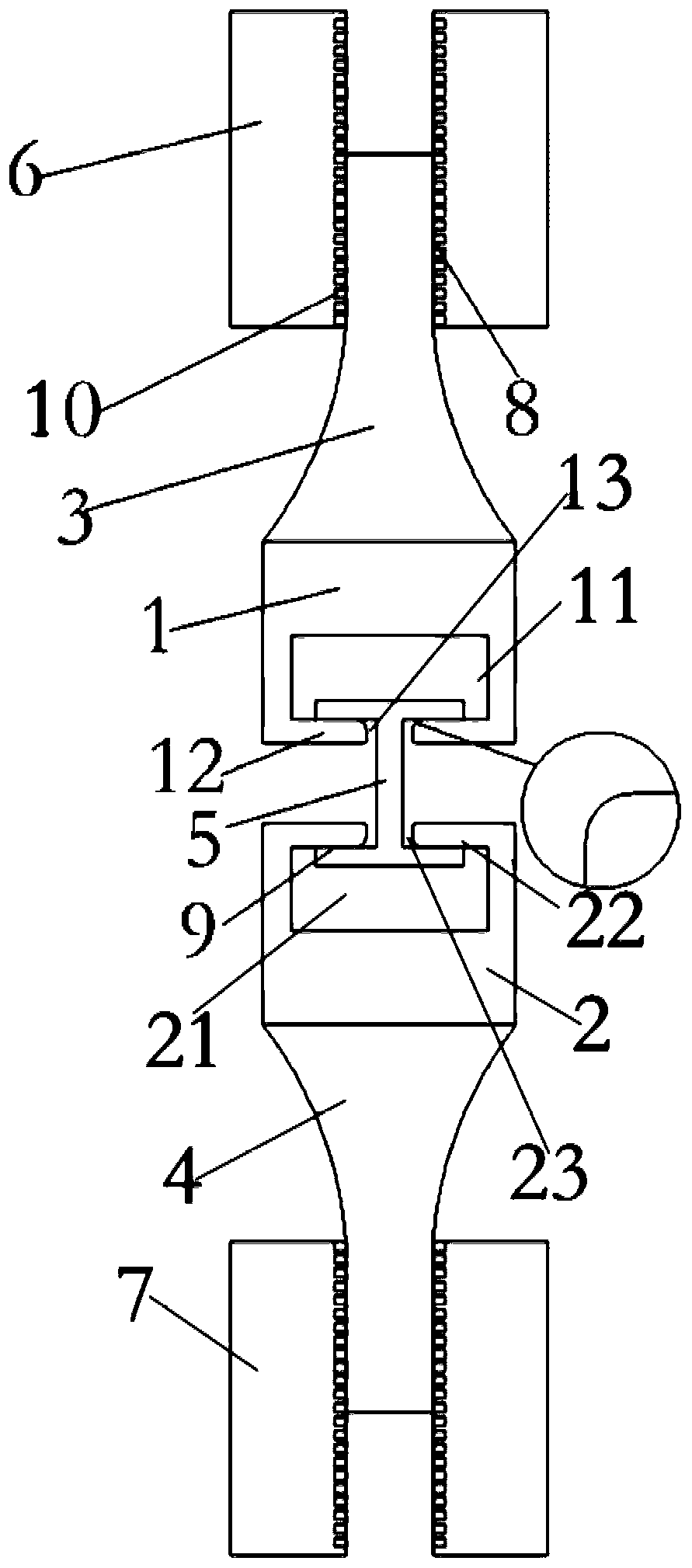

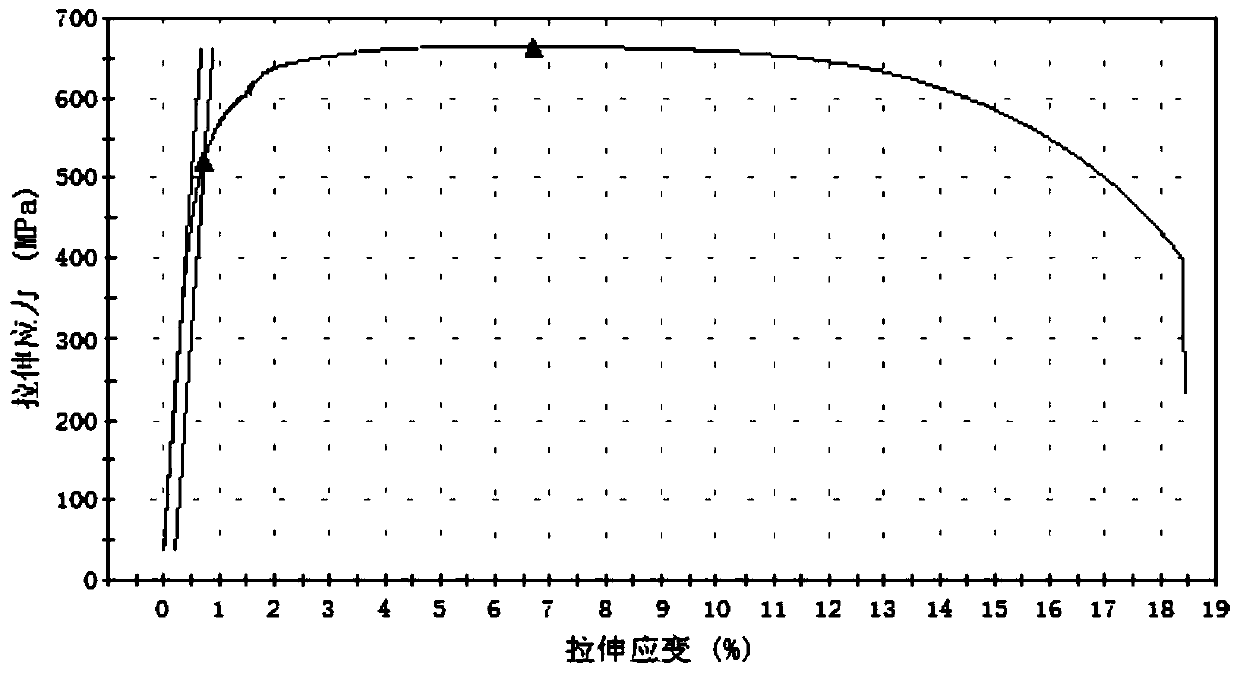

[0053] In Example 1, a tensile test is carried out on fine-grain annealed pure titanium by using a tensile clamping device for a metal plate sample according to the present invention.

[0054] Firstly, the commercially pure titanium undergoes severe plastic deformation at room temperature, combined with low-temperature annealing process, to prepare a fine-grain annealed pure titanium plate sample;

[0055] Then, the plate-shaped fine-grain annealed pure titanium is processed into a small plate-shaped sample with a length of 8 mm and a width of 2 mm in the parallel section of the sample body; wherein, the first round hole 13 and the second round hole 23 on the mold are clamped up and down. The diameter is 3-5mm;

[0056] Secondly, use 600#, 800#, 1000#, 1200#, 1500#, 2000# sandpaper to carry out rough grinding and fine grinding on the fine-grained annealed pure titanium plate-shaped small sample, and then use gold silk flannelette to manually grind the sample Polishing to ensu...

Embodiment 2

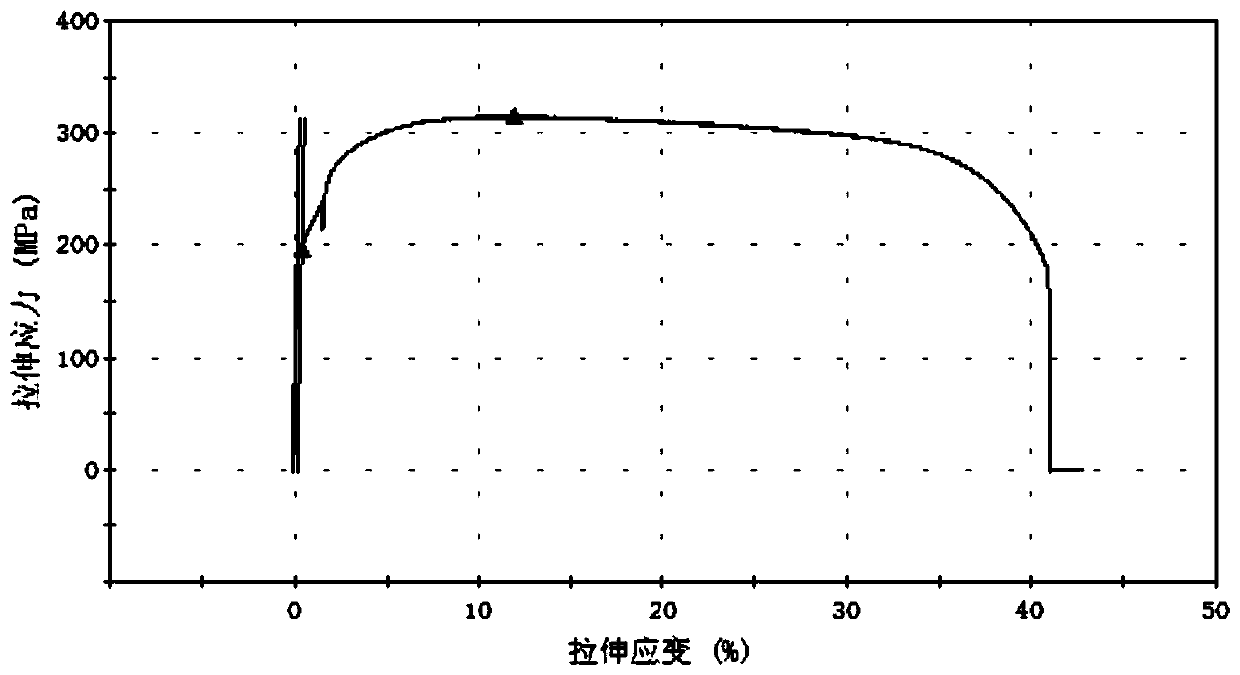

[0062] In Example 1, a tensile test is carried out on fine-grain annealed pure titanium by using a tensile clamping device for a metal plate sample according to the present invention.

[0063] First, grind the plate-shaped industrial pure titanium into a small plate-shaped sample with a length of 6 mm and a width of 2 mm in the parallel section of the sample body; among them, the first round hole 13 and the second round hole 23 on the mold are clamped up and down. The diameter is 3-5mm.

[0064] Then, use 400#, 600#, 800#, 1000#, 1200#, 1500#, and water sandpaper to carry out rough grinding and fine grinding processes on the small industrial pure titanium samples until the surface is smooth, and then use a polishing cloth to grind the industrial pure titanium. The titanium sample is mechanically polished to ensure that the surface of the industrial pure titanium sample is as smooth as a mirror without cracks;

[0065] Secondly, set anti-skid pads between the upper base and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com