Test water pressure applying device for shield tunnel structural model

A technology for structural prototypes and shield tunnels, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of hoop anchor cables that are easy to break, hidden safety hazards, and affect test results, etc., to eliminate inflection points and Effects of stress concentration, ensuring construction and operation safety, and improving stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

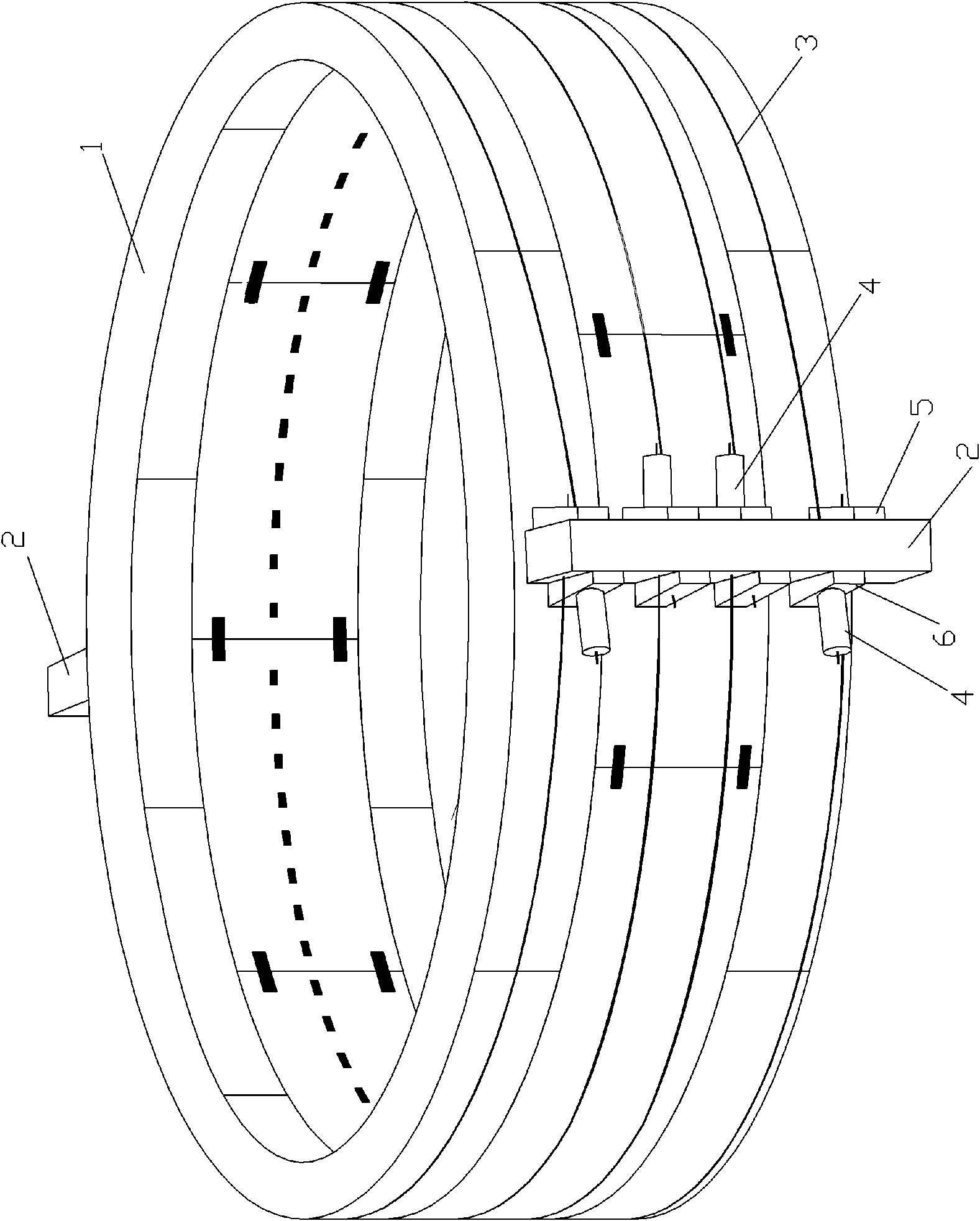

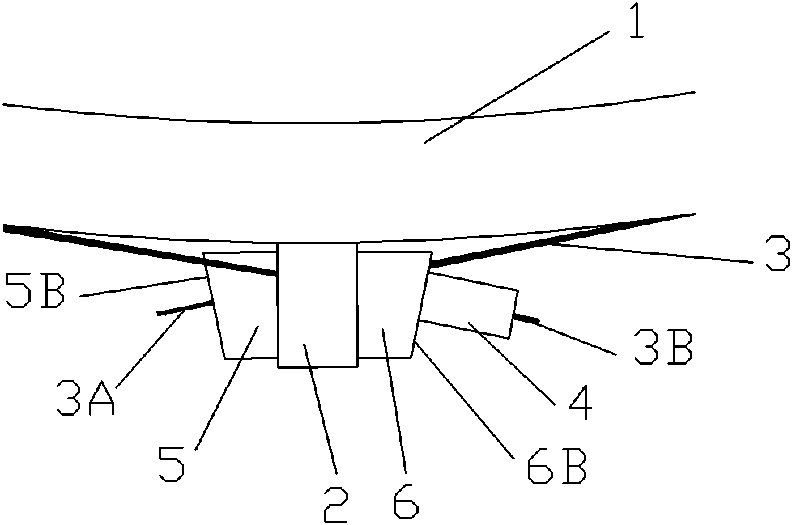

[0021] Figure 1-3 Shown, a kind of embodiment of the present invention is: a kind of shield tunnel structure prototype test water pressure application device, is provided with hoop beam 2 longitudinally on the outer peripheral surface of shield tunnel structure prototype 1, hoop anchor cable 3 The anchor end 3A passes through the anchor hole on the hoop beam 2, and then circles around the prototype 1 of the shield tunnel structure, and then the jack top 3B passes through the jack hole on the hoop beam 2 and the jack 4 on the side of the hoop beam 2 connected to the ejector rod, which is characterized in that:

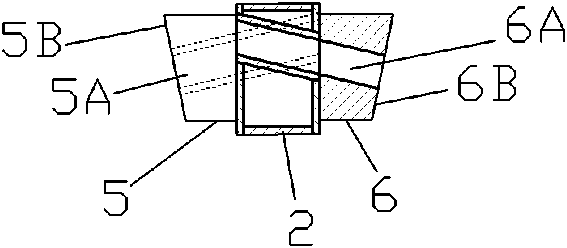

[0022] An anchoring backing plate 5 is also provided between the anchoring end 3A of the anchor cable 3 and the anchoring hole, and the anchoring backing plate 5 is provided with an anchoring through hole 5A connected with the anchoring hole. The through hole 5A is inclined, and the angle of inclination makes the anchor cable 3 pass through the anchor hole and the anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com