Low-gas permeability coal seam weakening and permeability increasing method combining presplitting and high-pressure water injection

A coal seam weakening and air permeability technology, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of small impact radius, low universality, and small impact radius of water injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

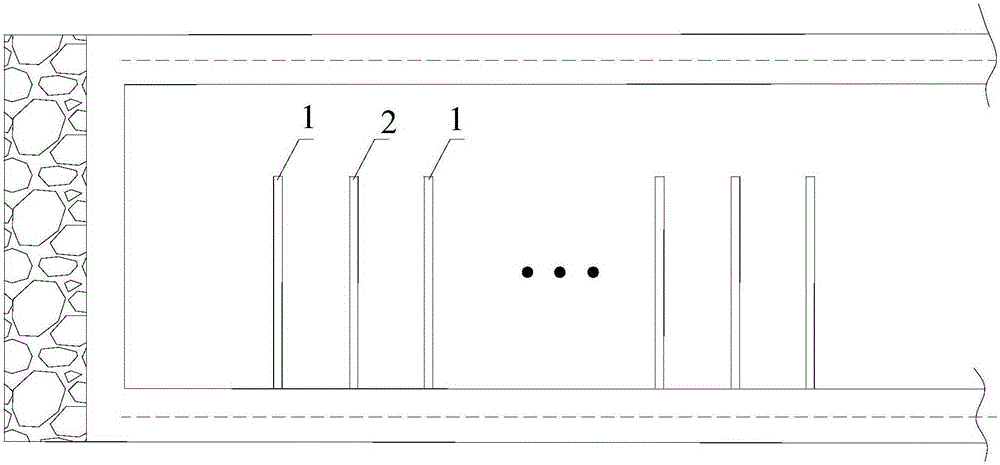

[0033] a. Use a drilling rig to construct a number of 100m-long boreholes on the side of the pre-mined coal seam in the working face, three of which are a coal seam weakening and anti-reflection unit, and the outermost two sides are pre-splitting holes 1, and the middle is high-pressure water injection Hole 2, the distance L between the pre-splitting hole 1 and the high-pressure water injection hole 2 is 10m, and the distance between the high-pressure water injection holes 2 in the two groups of coal seam weakening and anti-reflection units is 20m;

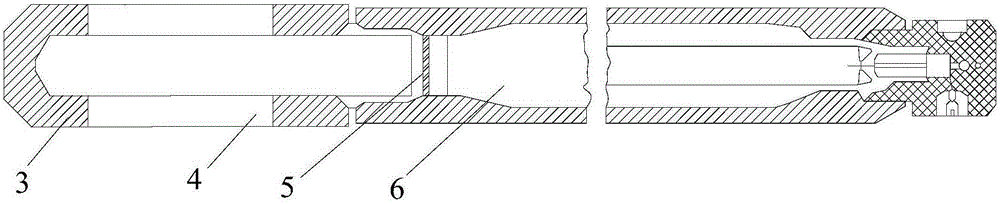

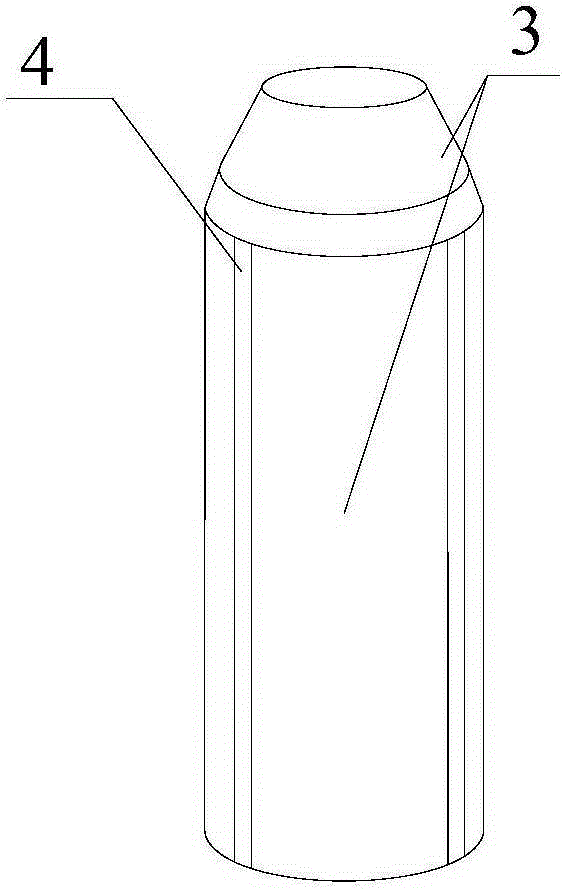

[0034] b. adopt multiple special installation rods 8 connected together to send the pre-splitting device 13 into the pre-splitting hole 1, the filling amount of liquid carbon dioxide in the pre-splitting device 13 is determined according to the physical parameters of the coal body, the length of the pre-splitting device 13 is 30m, It is sent to the depth of 85m corresponding to the pre-splitting hole 1 (including the length of the ...

Embodiment example 2

[0039] a. Use a drilling rig to construct a number of 120m-long boreholes on the side of the pre-mined coal seam in the working face. Three of the boreholes are a coal seam weakening and anti-reflection unit. The outermost two sides are pre-splitting holes 1, and the middle is high-pressure water injection Hole 2, the distance L between the pre-splitting hole 1 and the high-pressure water injection hole 2 is 10m, and the distance between the high-pressure water injection holes 2 in the two groups of coal seam weakening and anti-reflection units is 20m;

[0040] b. Adopting a plurality of special installation rods 8 connected together to send the pre-splitting device 13 into the pre-splitting hole 1, the filling amount of liquid carbon dioxide in the pre-splitting device 13 is determined according to the physical parameters of the coal body, and the length of the pre-splitting device 13 is 40m. It is sent to the depth of 100m corresponding to the pre-splitting hole 1 (including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com