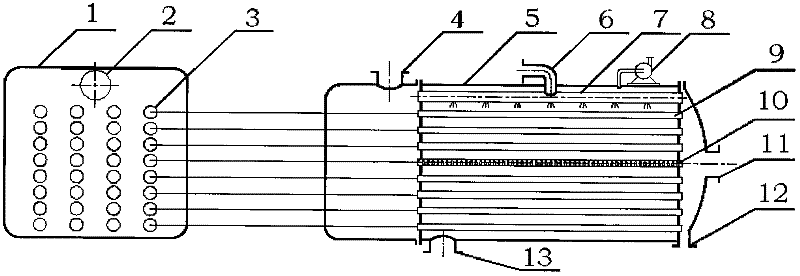

Shell-and-tube heat exchanger with stock pusher

A technology of shell-and-tube heat exchangers and pushers, which is applied in the field of shell-and-tube heat exchangers and heat transfer equipment to achieve the effects of solving blockage, improving flow conditions, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

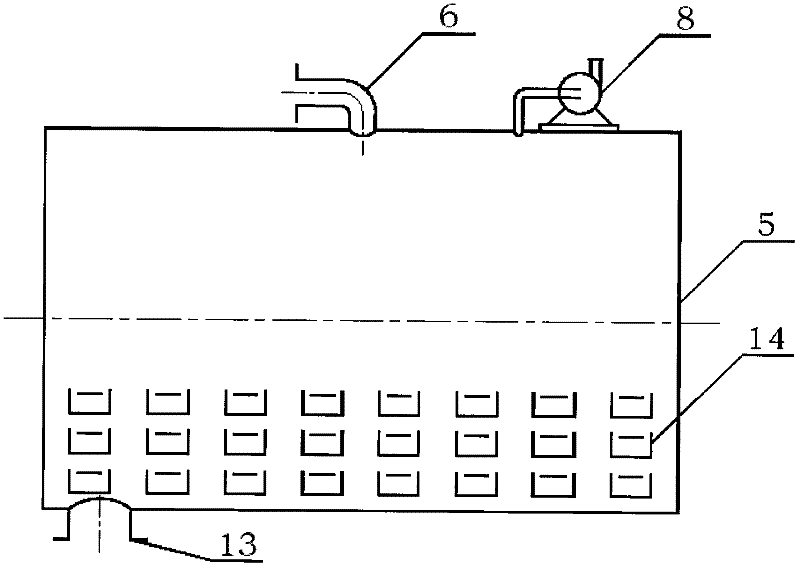

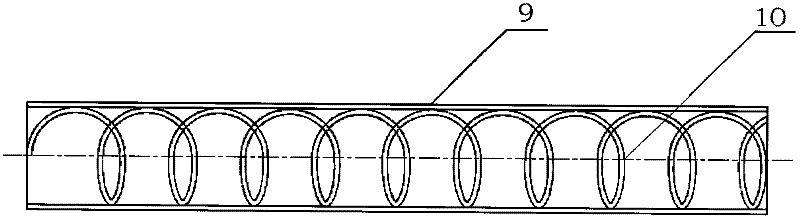

Method used

Image

Examples

Embodiment

[0015] Implementation example: use the shell-and-tube heat exchanger with pusher in the present invention to lower the temperature of the coke oven gas. In addition to hydrogen and methane, coke oven gas also contains coke and coal tar with a mass fraction of about 10%. The coke oven gas enters the heat exchange tube with a pusher from the material inlet pipe, and releases heat to the cooling water sprayed by the water spray device. As the temperature decreases, the coke and coal tar in the coke oven gas will continue to adhere On the inner wall of the heat exchange tube, it is pushed out by the rotating pusher. The mass fraction of coke and coal tar in the coke oven gas discharged from the material outlet pipe is only 0.1%, thereby achieving the purpose of removing coke and coal tar in the coke oven gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com