Improved delayed coking process

A delayed coking and process technology, which is used in the coking of carbon-containing materials, coke ovens, petroleum industry, etc., can solve the problems of high investment and energy consumption, and the tendency of coking heating furnace tubes to increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

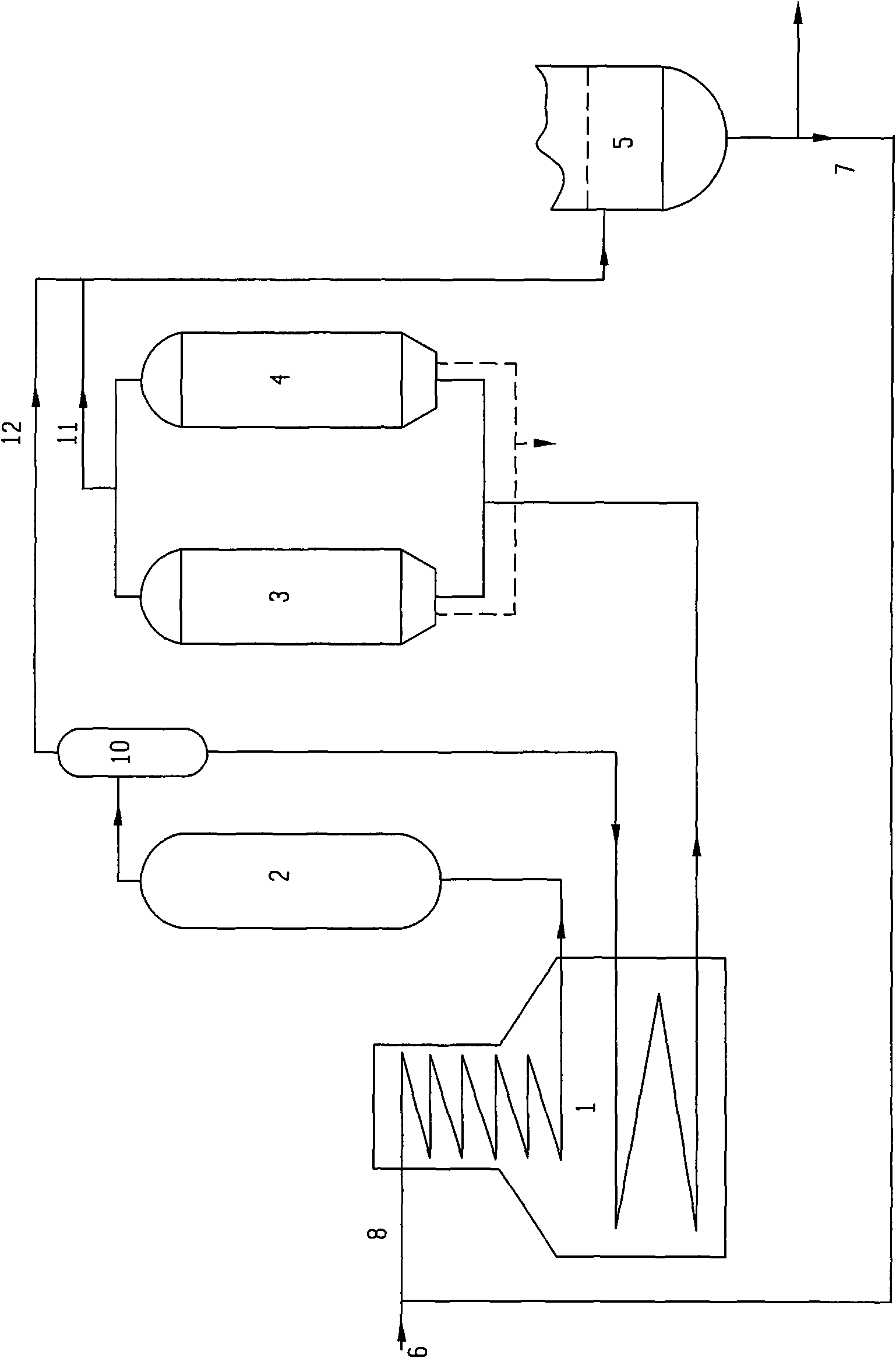

[0043] Heavy oil I at 150°C (see Table 1 for its properties) is mixed with circulating oil from the coking fractionation tower and then mixed with 0.65% high-temperature steam, and then enters the preheating furnace (that is, the convection chamber of the heating furnace of the delayed coking industrial device) for heating , the temperature of the material at the outlet of the preheating furnace is controlled to be 385°C; the material exiting the preheating furnace enters the upflow visbreaking reactor for visbreaking, the material stays in the visbreaking reactor tower for 156min, and the top temperature of the visbreaking reactor is 377°C , The gauge pressure is 0.29MPa (to overcome the resistance of the system).

[0044] The visbroken mixture from the visbreaking reactor enters the gas-liquid separation tank for gas-liquid separation. The separated high-temperature oil gas is mixed with the oil gas from the top of the coking tower and then separated in the decoking fractiona...

Embodiment 2

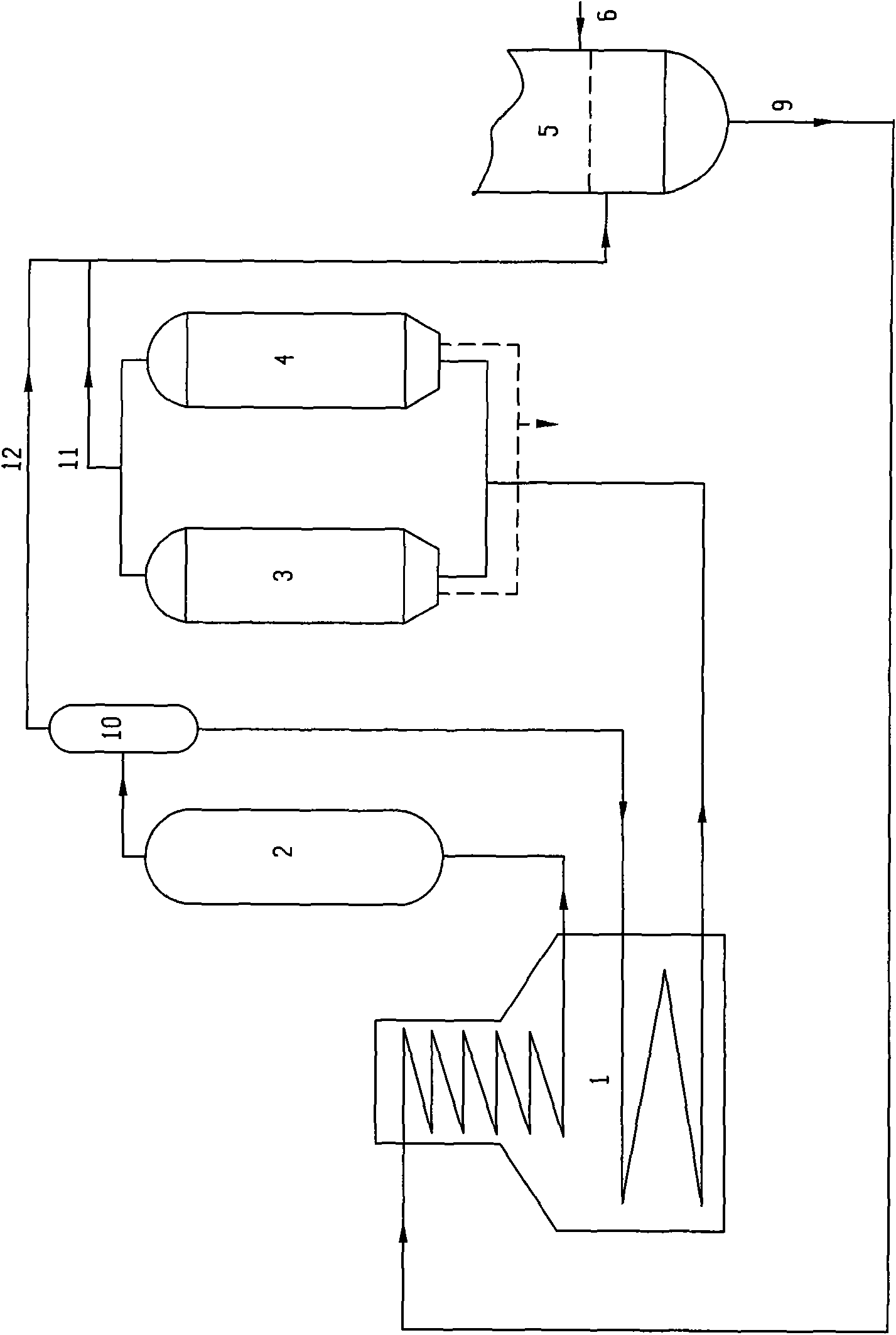

[0053] The 150°C heavy oil II (properties are listed in Table 3) is mixed with the circulating oil from the coking fractionation tower and then mixed with 0.50% high-temperature steam, and then enters the preheating furnace (that is, the convection chamber and radiation chamber of the delayed coking industrial device heating furnace) chamber) heating, the temperature of the control preheating furnace outlet material is 417 ℃; other processes are the same as embodiment 1, and the operating conditions are listed in table 4.

Embodiment 3

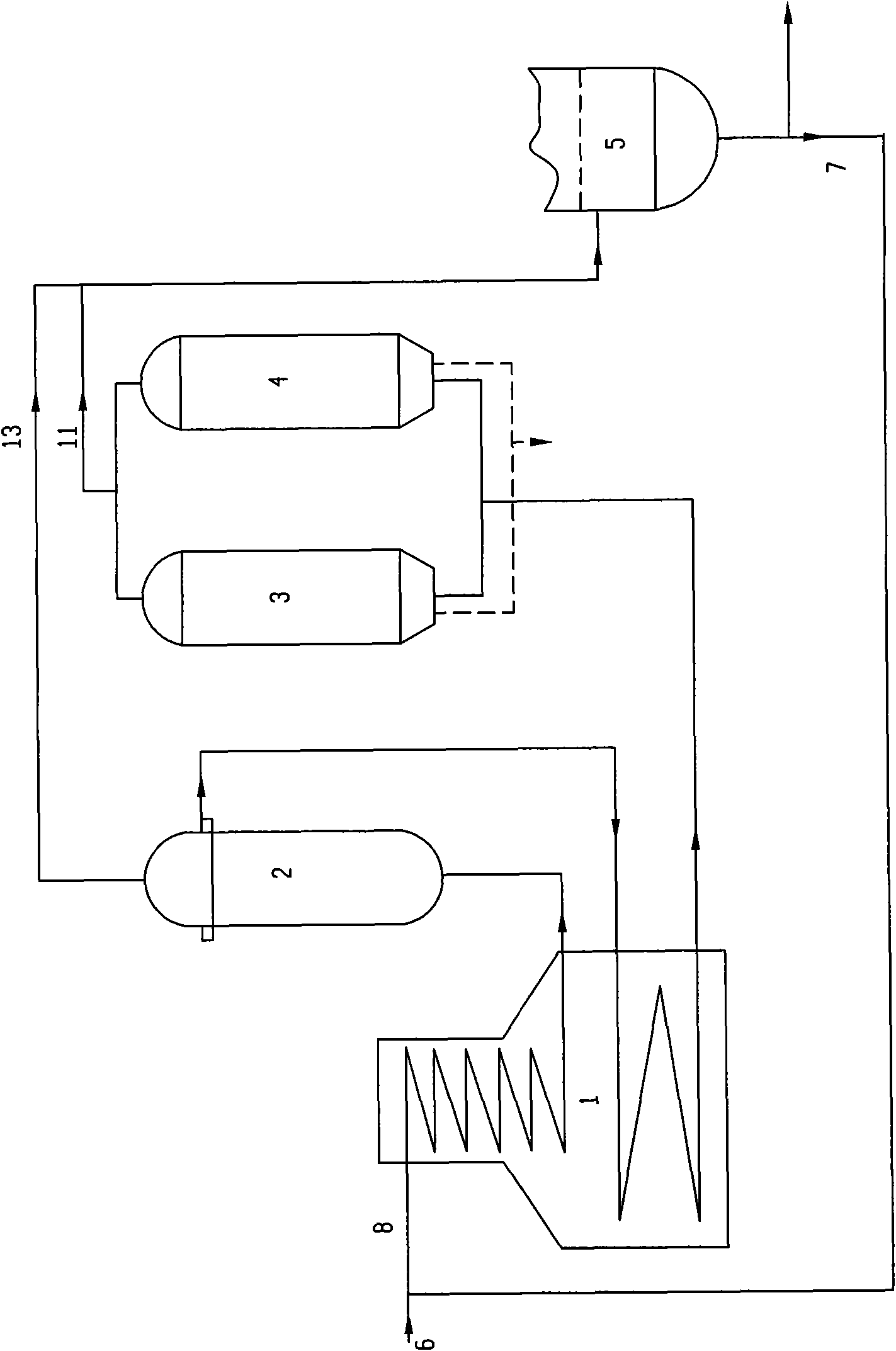

[0062] Investigation on coking tendency of heavy oil and its visbroken in heating furnace tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com