Merged propeller blade type electro-catalytic reactor for high-viscosity wastewater treatment

A technology for wastewater treatment and reactor, applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problem of difficulty in significantly improving the effect of pollutant treatment, and achieve the effects of novel equipment structure, uniform distribution and fast electrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

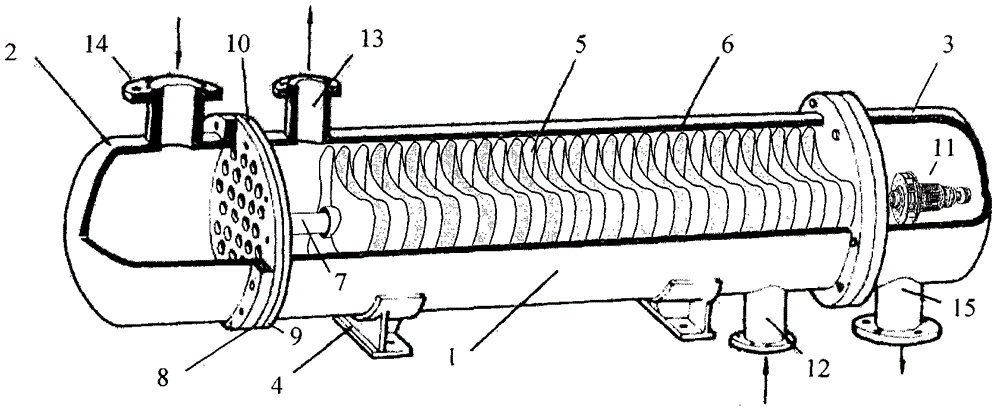

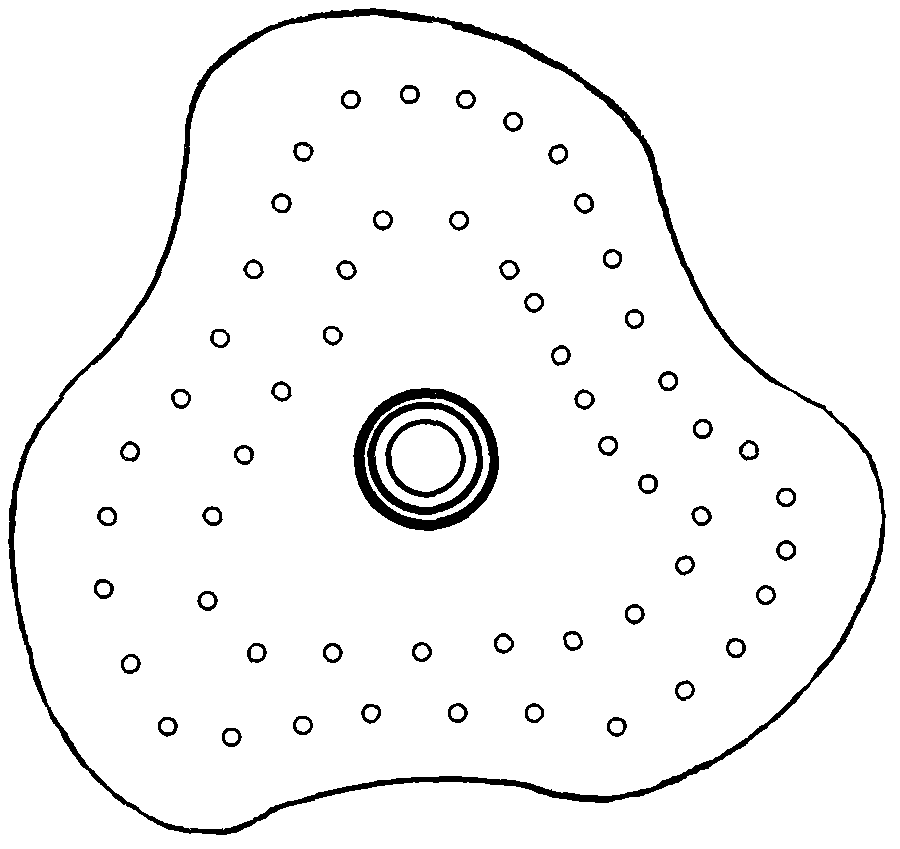

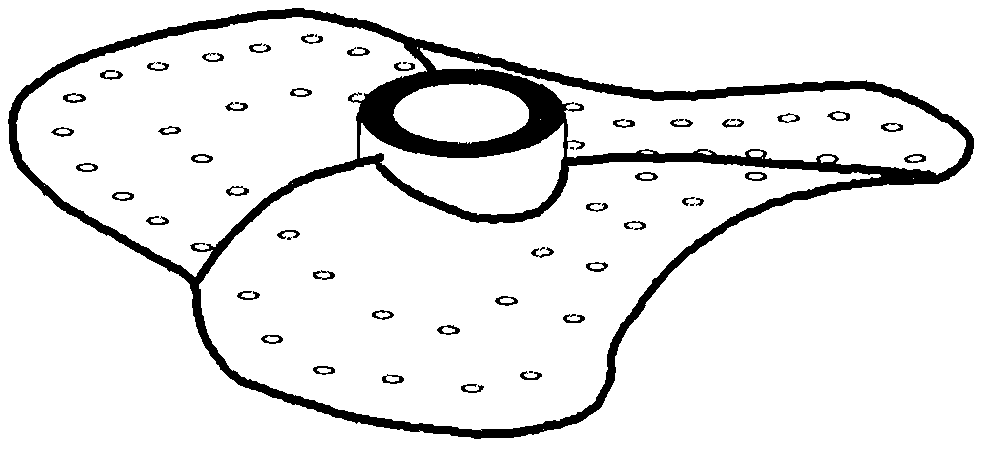

[0020] Such as figure 1 As shown, a fusion paddle-type electrocatalytic reactor for high-viscosity wastewater treatment is characterized in that the shell of the reactor is made of a cylindrical shell 1 made of glass fiber reinforced plastic, an upper floating head 2 and a lower floating head 3 through the method The cast iron base 4 provides horizontal support for the reactor as a whole; the paddle anode 5 and the paddle cathode 6 are cathode and anode plates in the form of fusion propellers, and their materials are titanium-based lead oxide and pure titanium respectively, and the paddle anode 5 Interlaced with the blade cathode 6 and fixed on the conduction shaft 7, one end of the conduction shaft 7 is connected to the anode guide plate 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com