Helical propelling rotation heat pipe heat exchager

A heat pipe heat exchanger and heat pipe technology, applied in the direction of moving pipe heat exchanger, heat exchanger type, indirect heat exchanger, etc., can solve the problems of large flow resistance, affecting heat transfer effect, uneven heating or cooling, etc. To achieve the effect of delaying the formation of scale layer, improving heat transfer efficiency and improving flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

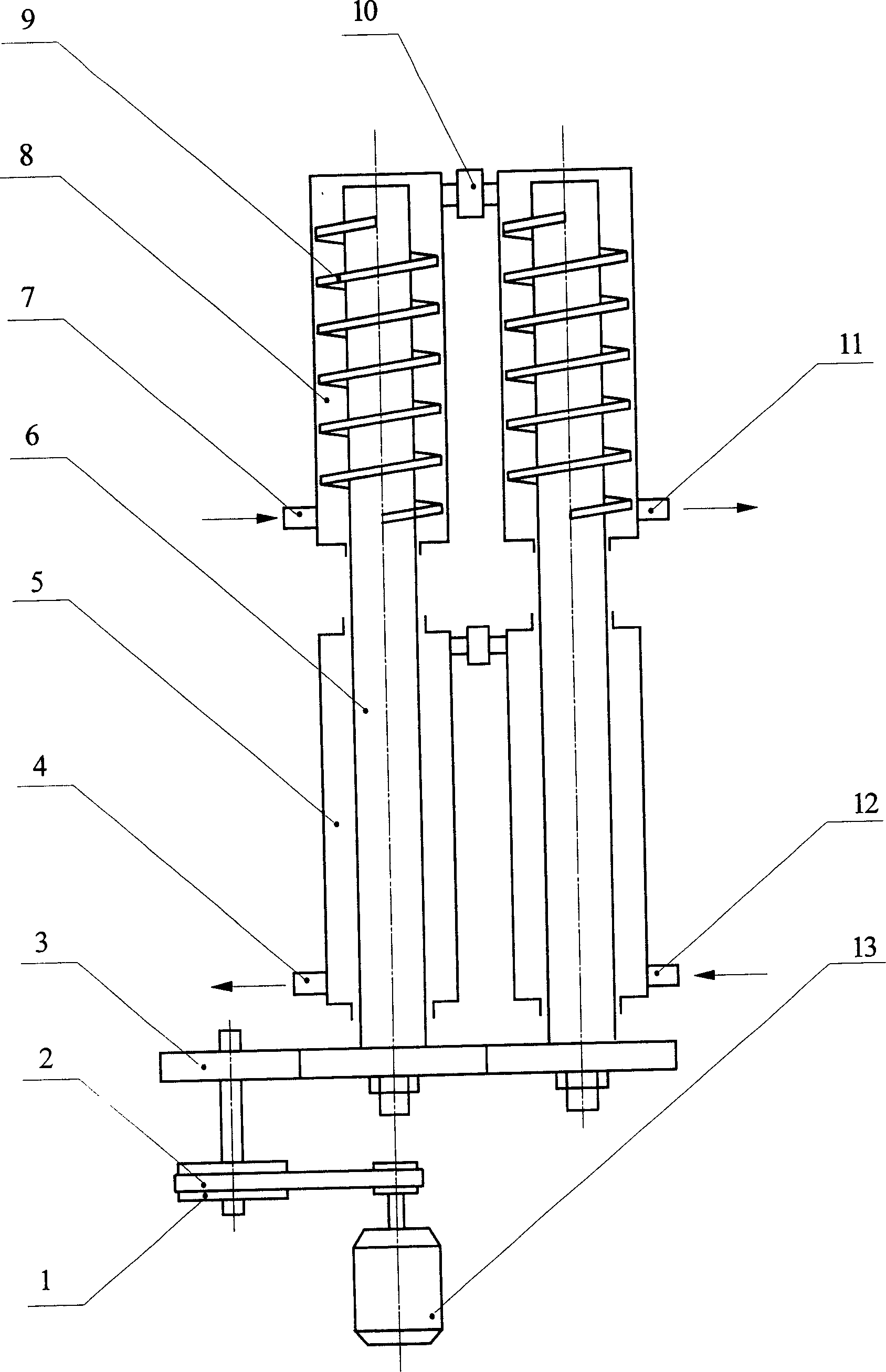

[0010] in figure 1 The high-viscosity material enters the heating section of the spiral-propelled rotating heat pipe (6) through the high-viscosity material inlet pipe (7) to be heated. At the same time, the spiral piece (9) pushes the material in the heat pipe (6) and heater It flows forward in the spiral passage between the jackets (8), and is transferred to the next stage (if necessary) for further heating at the end via a communication union (10). After heating, it flows out through the outlet pipe (11). The heating fluid heats and vaporizes the working fluid in the heat pipe via the sleeve at the bottom of the heat pipe heat exchanger. If it is necessary to cool the high-viscosity heat-sensitive fluid, just place the helical section of the heat pipe below and let the high-viscosity heat-sensitive fluid pass from below.

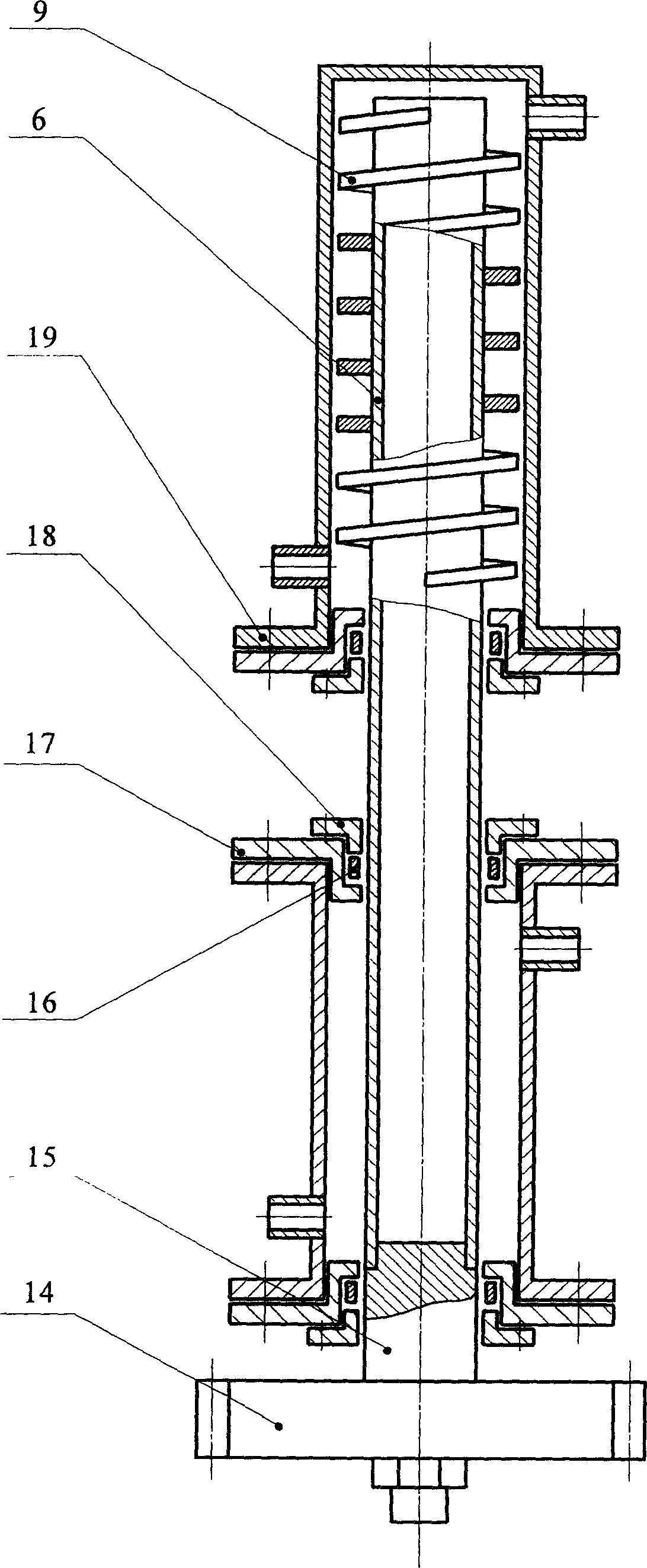

[0011] figure 2 It shows the cross-sectional structure of the spiral rotating heat pipe heat exchanger. A single helical rotary heat pipe heat exchanger is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com