Cyclone fine mist spray head

A fine water mist nozzle, cyclone technology, applied in the direction of spraying device, spraying device, etc., can solve the problem of enhancing turbulent flow intensity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

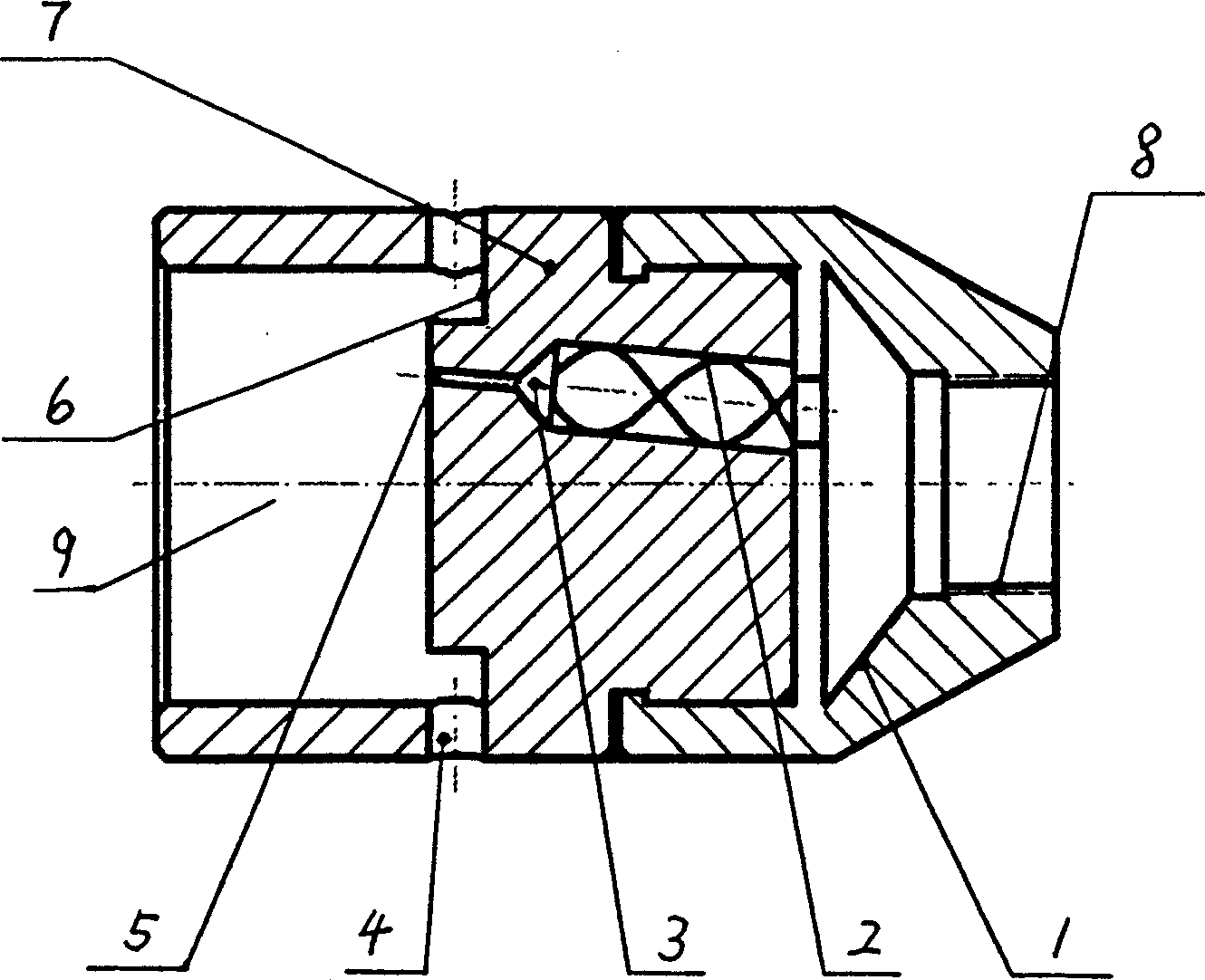

[0005] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0006] There is a large blind hole 9 at the end of the nozzle body 7, and an airflow booster hole 4 communicating with the large blind hole is arranged on the periphery. The nozzle holder 1 is connected together, the mixing chamber communicates with the big blind hole through the nozzle hole 5, the inner opening of the airflow booster hole is placed in the groove 6, and the end of the cyclone nozzle holder has an assembly hole 8 with an inner hole thread; in order to ensure the use effect , the diversion column installed in the mixing chamber 3 is a space three-dimensional curved diversion column; the mixing chamber 3 formed by the elongated holes is at least 2, generally 2-7; the airflow booster hole 4 At least one, generally 1-6; because there are no moving parts inside the nozzle, it is made of copper alloy or stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com