Marine large-bore natural gas engine precombustion chamber porous jet flow ignition type efficient combustion system

A technology of porous jet and combustion system, which is applied in the direction of gaseous engine fuel, fuel system, engine components, etc., to shorten the flame propagation distance, improve the turbulence intensity, and improve the combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

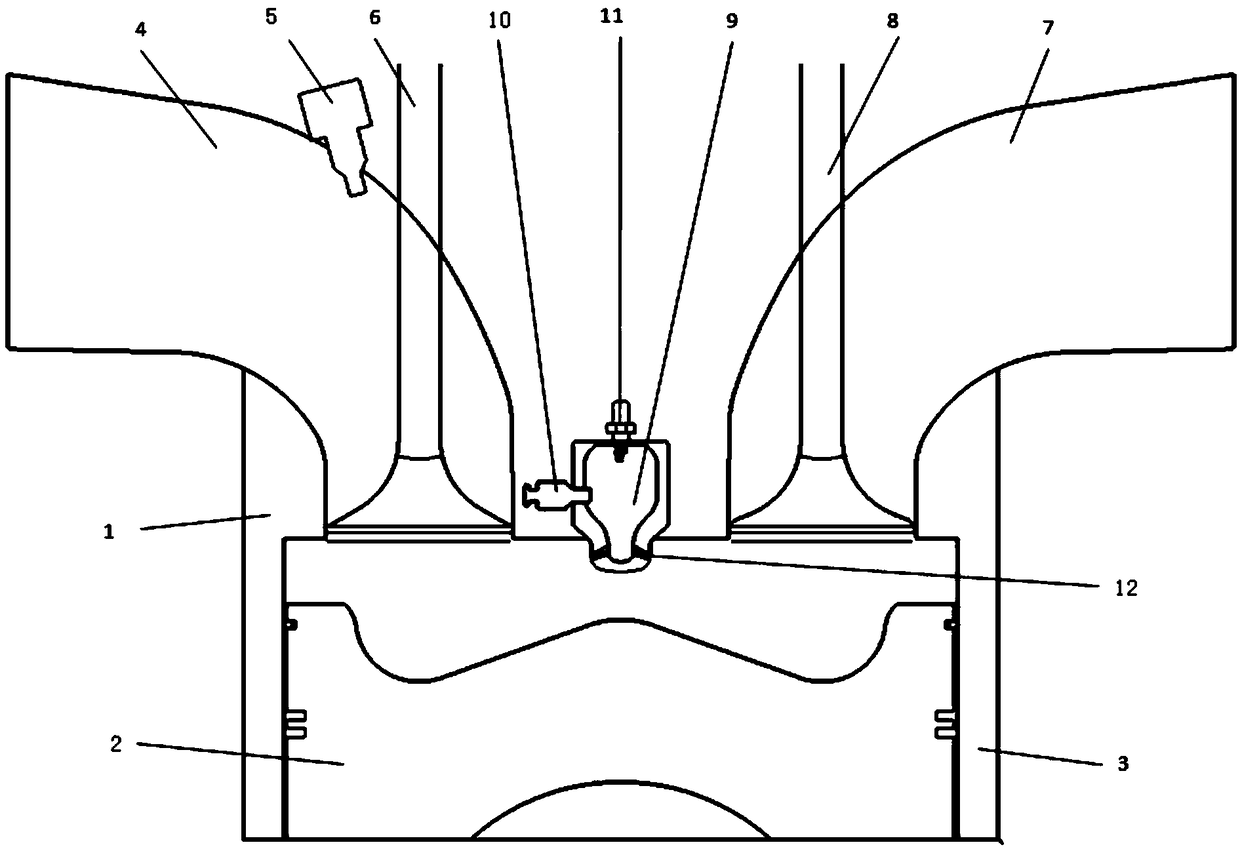

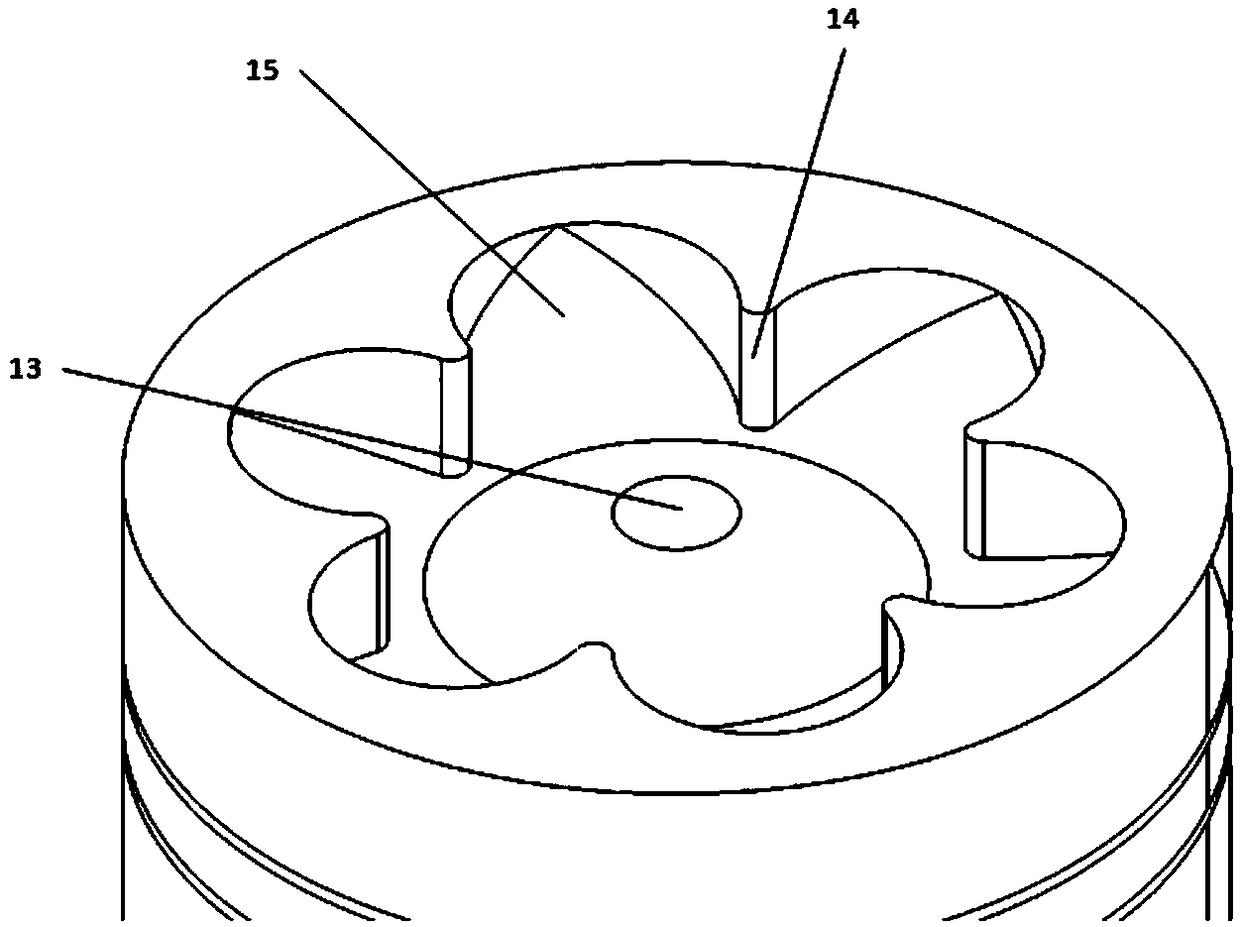

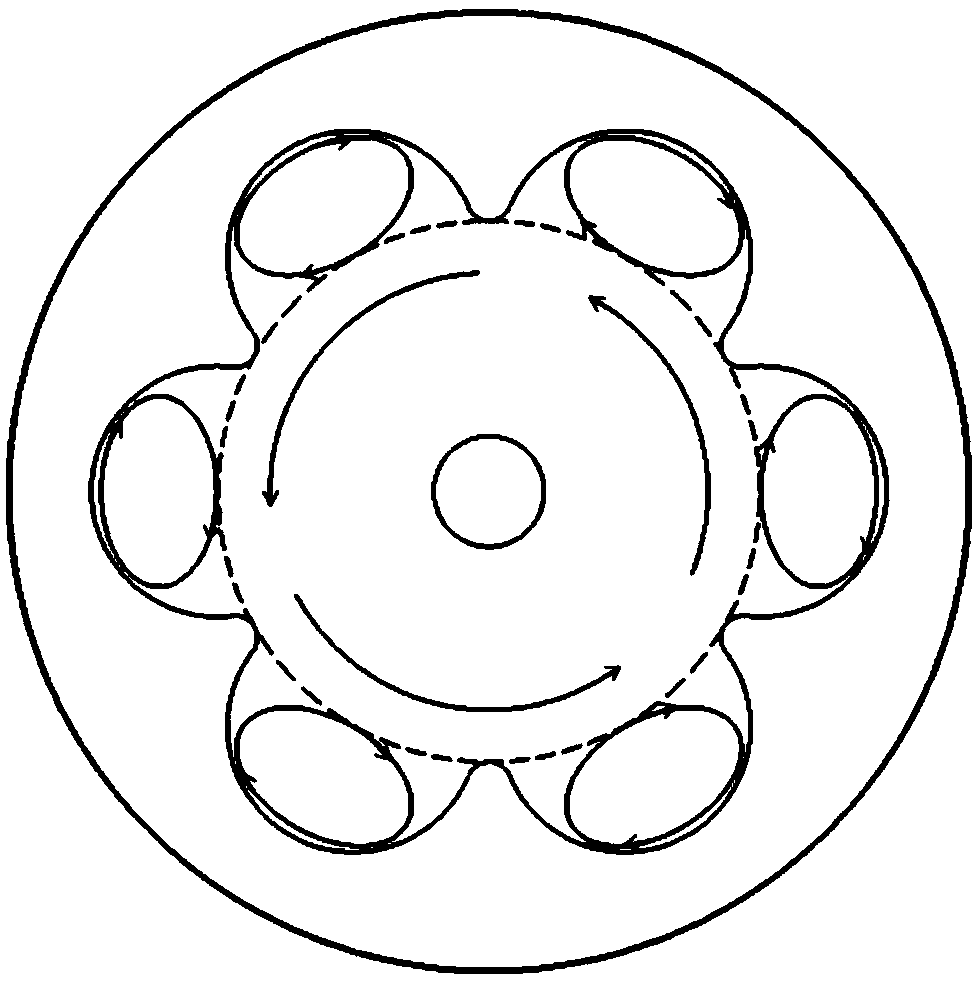

[0026] to combine Figure 1-5 , a marine large-bore natural gas engine pre-combustion chamber porous jet ignition high-efficiency combustion system, comprising an intake port 4, a natural gas supply device 5, an intake valve 6, an exhaust port 7, an exhaust valve 8, a pre-combustion Chamber 9, pre-chamber natural gas injection device 10, spark plug 11 and a main combustion chamber consisting of cylinder head 1, piston 2 and cylinder liner 3. There are two sets of natural gas supply devices, one set of natural gas supply device 5 is installed on the intake duct 4 for supplying lean gas to the main combustion chamber; Too rich gas is supplied. The intake port 4 is a spiral intake port. The structure of the spiral intake port allows the mixture of natural gas and air to flow around the central axis of the cylinder after entering the cylinder, forming a large-scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com