Passive containment cooling system keeping dynamic circulation of cooling water

A passive containment and dynamic circulation technology, applied in cooling devices, nuclear power generation, climate sustainability, etc., to achieve the effects of improving reliability, avoiding dry spots, and improving heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

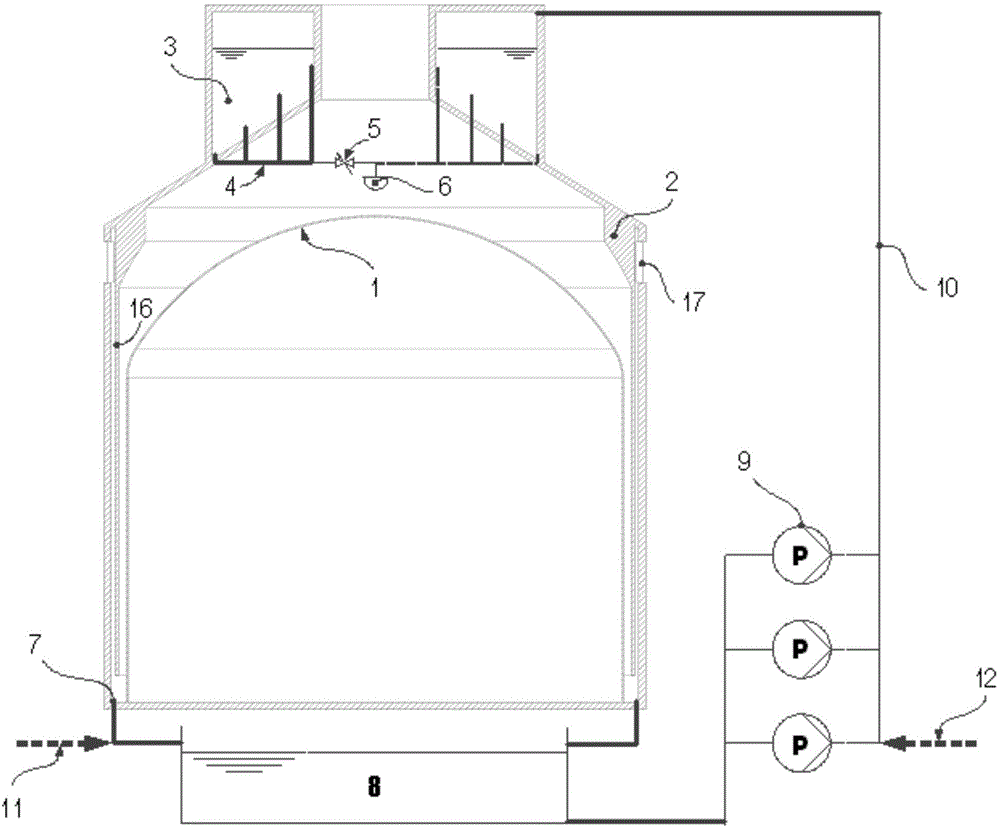

[0022] Such as figure 1 As shown, a passive containment cooling system for maintaining dynamic circulation of cooling water includes a steel containment vessel 1 arranged in a shielded building 2, and an air baffle 16 is arranged inside the air inlet 17 of the shielded building, and the shielded The upper part of the plant building 2 is provided with a roof-mounted water tank 3, and the containment spray pipeline 4 arranged above the steel containment vessel 1 is connected to the roof-mounted water tank 3. The containment sprinkler pipeline 4 is connected with the generalized passive fluid control unit 5 and the sprinkler head 6 connected to form a spray path, the generalized passive fluid control unit 5 is kept normally open, so that the water source in the top water tank 3 can continue to spray through the spray path, and the spray water forms on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com