Device and method for coagulating fine particles under tangentially circular cyclone atomization and sound wave action

A fine particle and sound wave technology, applied in the field of gas-solid fine particle removal, can solve the problems of high energy consumption, large pressure drop, noise hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

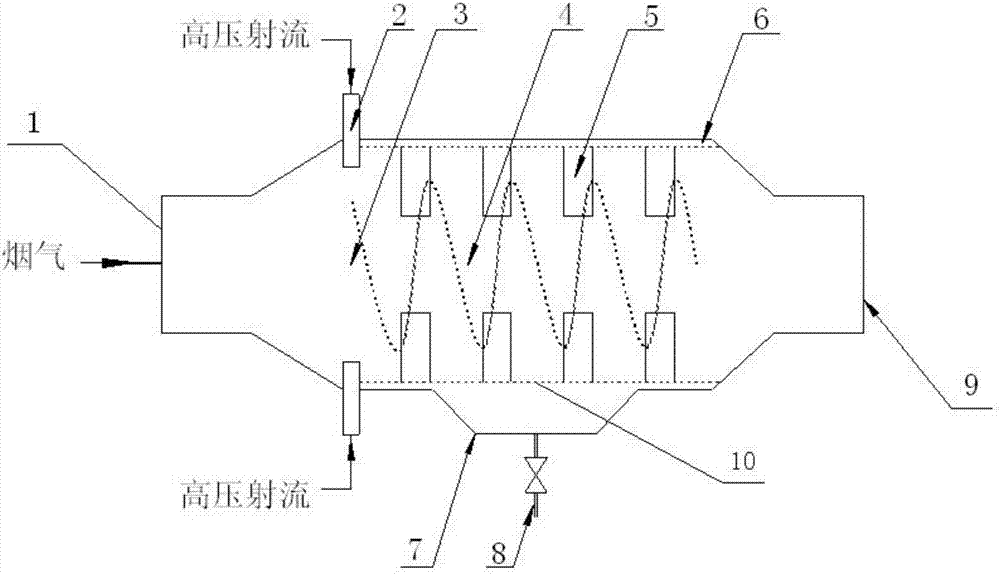

[0040] Such as Figures 1 to 4 shown. The invention discloses a device for coagulating fine particles by tangential swirl atomization and acoustic wave action, which includes the following components:

[0041] Double-layer cylinder body 6; the front and rear ends of the double-layer cylinder body 6 are smoke gas inlet 1 and smoke gas outlet 9 respectively;

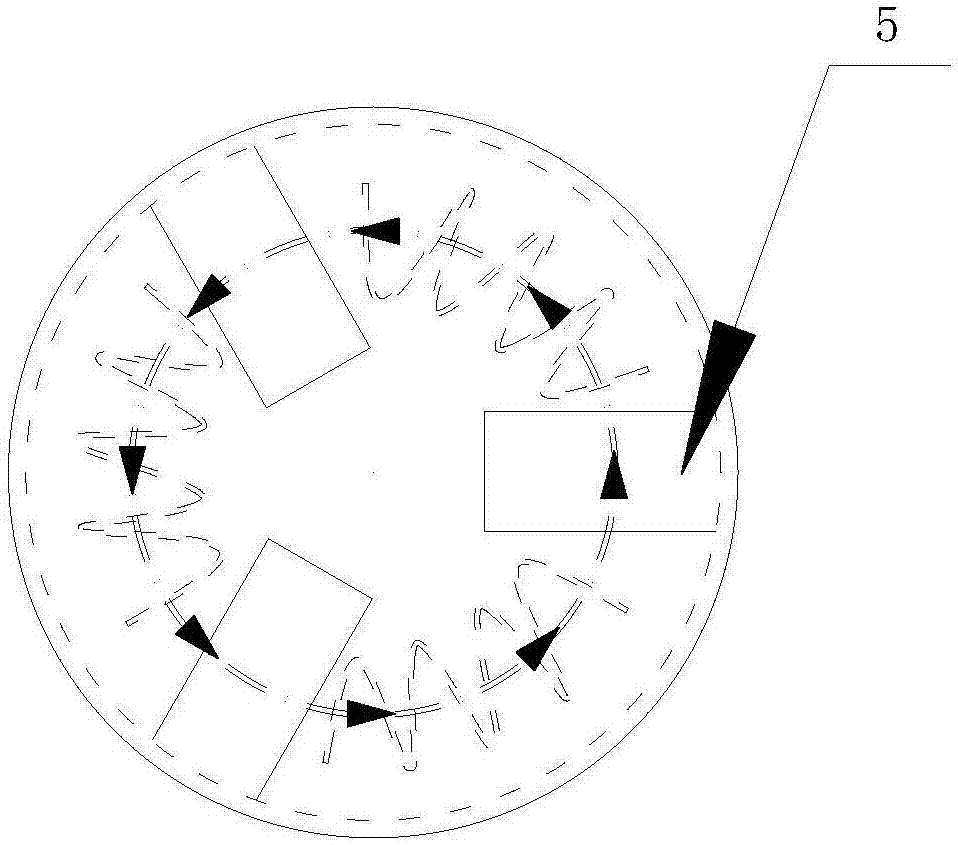

[0042] Condensation spoilers 5 distributed along the inner wall surface of the double-layer cylinder 6 in an array; the coagulation spoilers 5 arrayed on the inner wall surface of the double-layer cylinder 6 form a swirling flow condensation zone 4;

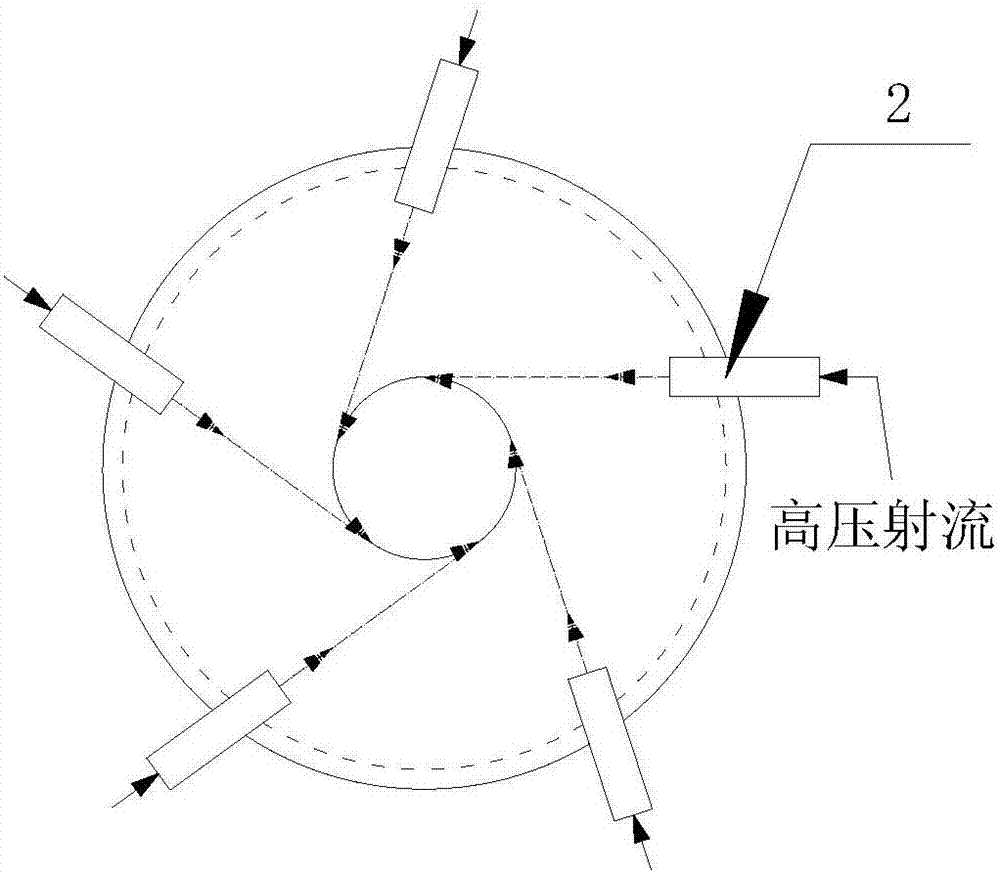

[0043] On the inner wall surface of the flue gas inlet 1 end of the double-layer cylinder 6, a plurality of swirl atomization acoustic turbulators 2 are arranged in an array and tangentially; the cross-sectional area surrounded by the swirl atomization acoustic turbulators 2 forms a high-pressure swirl The flow area 3; the swirling atomization acoustic turbulence device 2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com