Double-flow-mode fuel oil ground pre-washing method and device thereof

A dual-flow mode and pre-washing technology, which is applied in the direction of inert gas generation, can solve the problems of increasing oxygen concentration and oxygen content in nitrogen-rich gas, and achieve the effects of reducing oxygen concentration, efficient recovery, and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

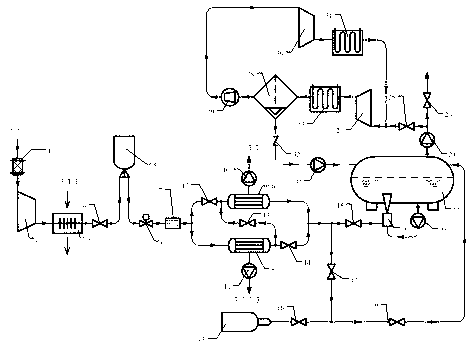

[0025] Such as figure 1 , the present invention mainly includes air compressor 2, nitrogen-enriched gas generator 8, 9, washing nozzle 16, vacuum pump 19, fuel vapor membrane separator 24.

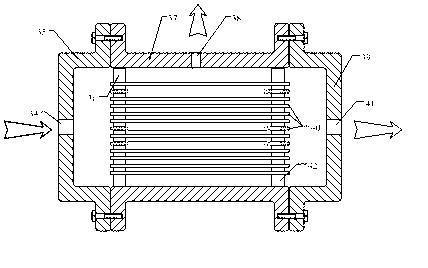

[0026] Such as figure 2As shown, the above nitrogen-enriched gas generators 8 and 9 adopt a horizontal fixed tube sheet structure, and the tube bundles are made of tubular hollow fiber membranes made of polyethylene membranes, polypropylene membranes, polytetrafluoroethylene membranes or polyvinylidene fluoride membranes. 40. The two ends of the plurality of tubular hollow fiber membranes 40 are respectively fixed on the left tube plate 36 and the right tube plate 42, and then installed in the cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com