Waste lubricating grease collecting structure of wind driven generator spindle bearing

A technology for wind turbines and waste lubricating oil, which is applied in the direction of engine lubrication, engine components, lubricating parts, etc., and can solve waste lubricating grease fires, insufficient replacement of new lubricating grease and waste lubricating grease, wind turbine pollution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

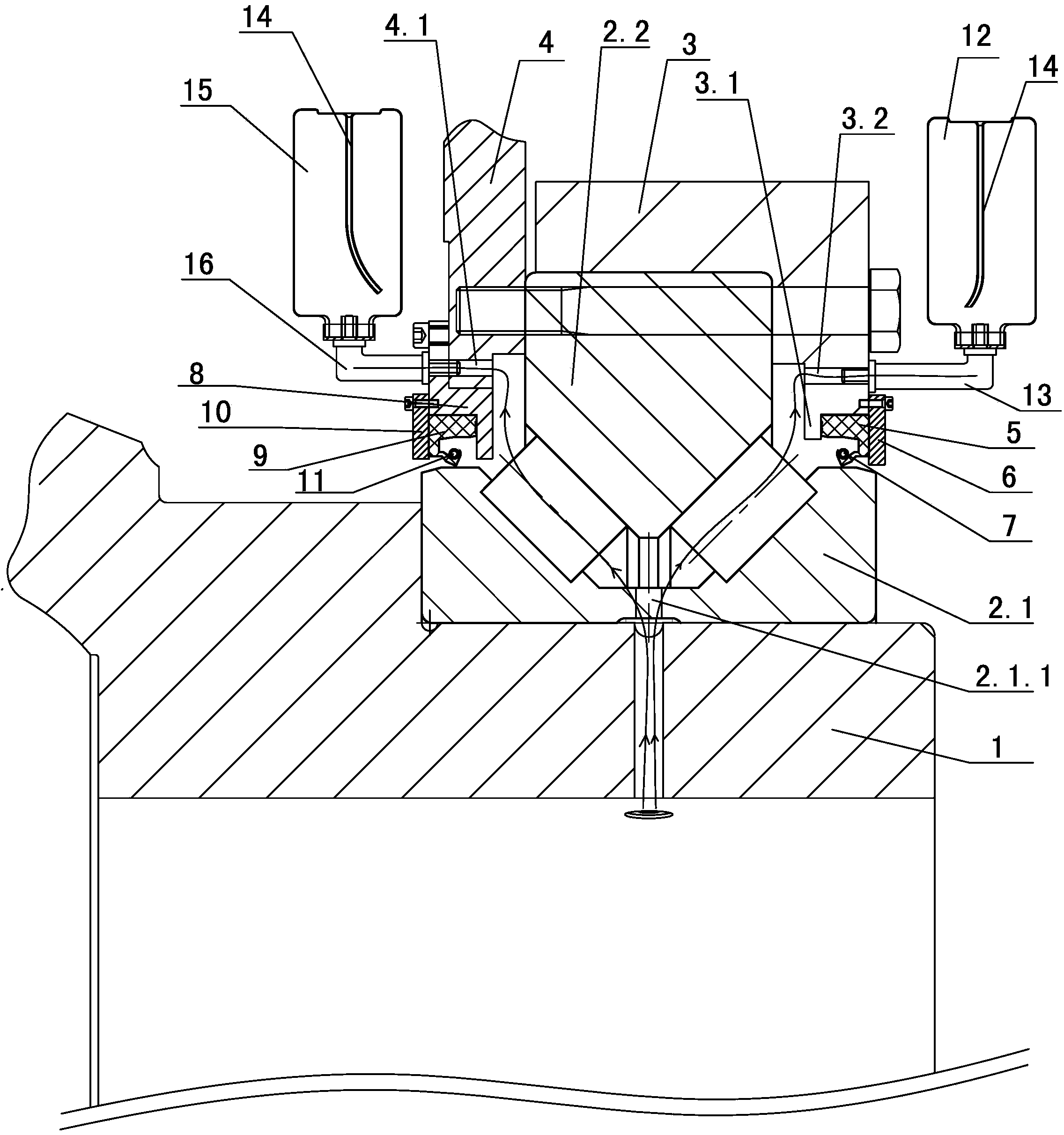

[0019] The collection structure of the main shaft bearing waste lubricating grease of embodiment 1 is as follows figure 1 As shown, the bearing inner ring 2.1 is fixed to the main shaft 1, the turntable 3 and the rotor 4 are respectively fixed on both sides of the bearing outer ring 2.2 by a plurality of bolts, a first sealing structure is provided between the turntable 3 and the bearing inner ring 2.1, and the rotor 4 There is a second sealing structure between the bearing inner ring 2.1.1, the first sealing structure and the second sealing structure are used to seal the oil in the movable cavity of the bearing roller, and the bearing inner ring 2.1 is provided with a communication oil supply device (Fig. Not shown in ) and the oil inlet hole 2.1.1 of the roller movable cavity; also includes the first oil collection assembly and the second oil collection assembly; the first oil collection assembly includes the first oil collection bottle 12 and the first oil passage pipe 13. ...

Embodiment 2

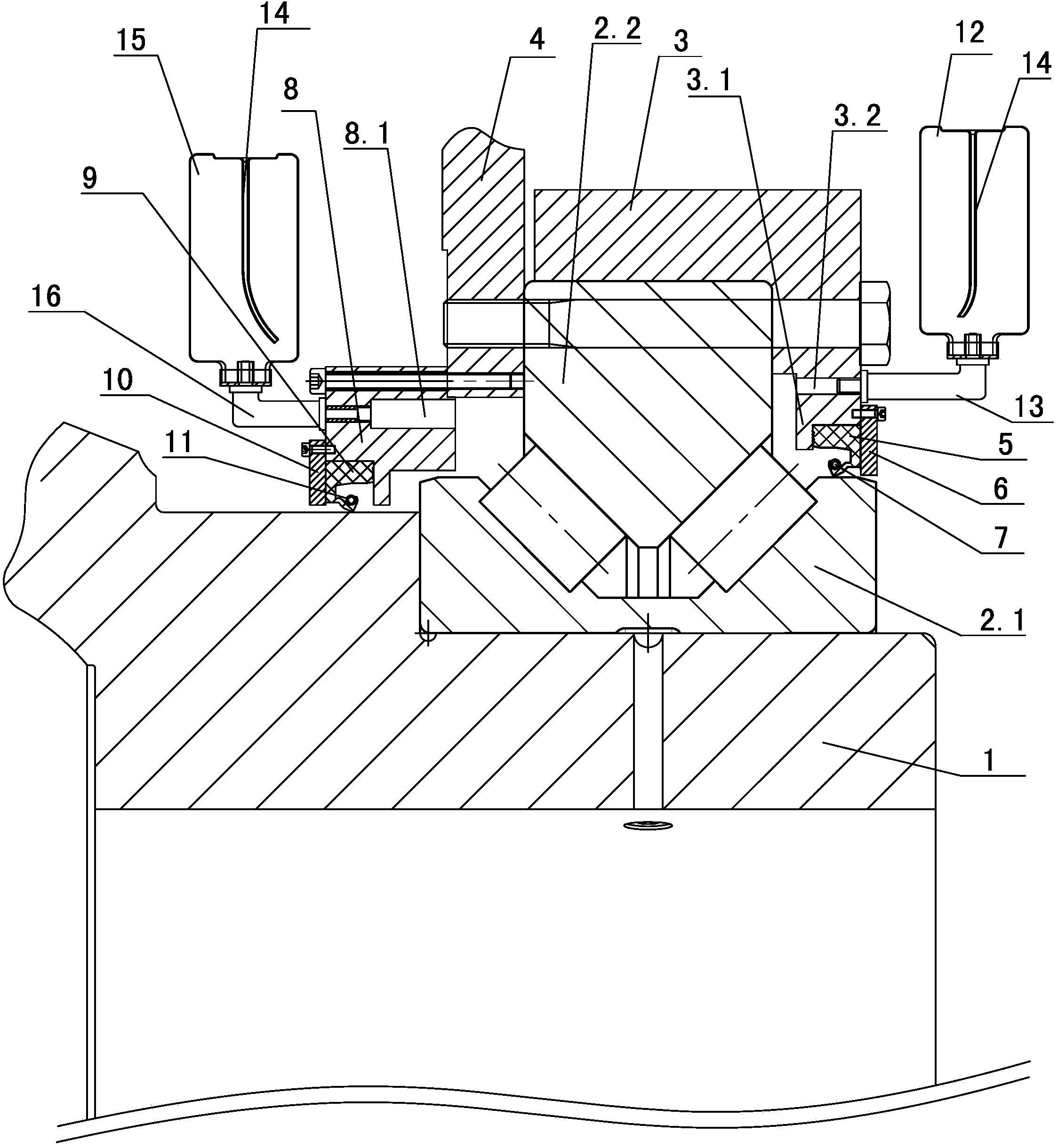

[0024] The first sealing structure and the first oil collecting assembly in embodiment 2 are the same as the first sealing structure and the first oil collecting assembly in embodiment 1, except that figure 2 As shown: 1. The second sealing structure includes a sealing seat 8, a second skeleton sealing ring 9 with a "V"-shaped opening facing the roller movable cavity, and a second sealing cover 10; the sealing seat 8 is fixed to the rotor 4 , the second sealing cover plate 10 is fixed to the sealing seat 8, the second skeleton sealing ring 9 is fixedly installed in the cavity surrounded by the sealing seat 8, the main shaft 1 and the second sealing cover 10, the second skeleton sealing ring 9 The opening is provided with a second spring fastening ring 11 for ensuring the sealing fit between the second skeleton sealing ring 9 and the main shaft 1 . 2. The second oil collection assembly includes a second oil collection bottle 15 and a second oil passage pipe 16. The second oil ...

Embodiment 3

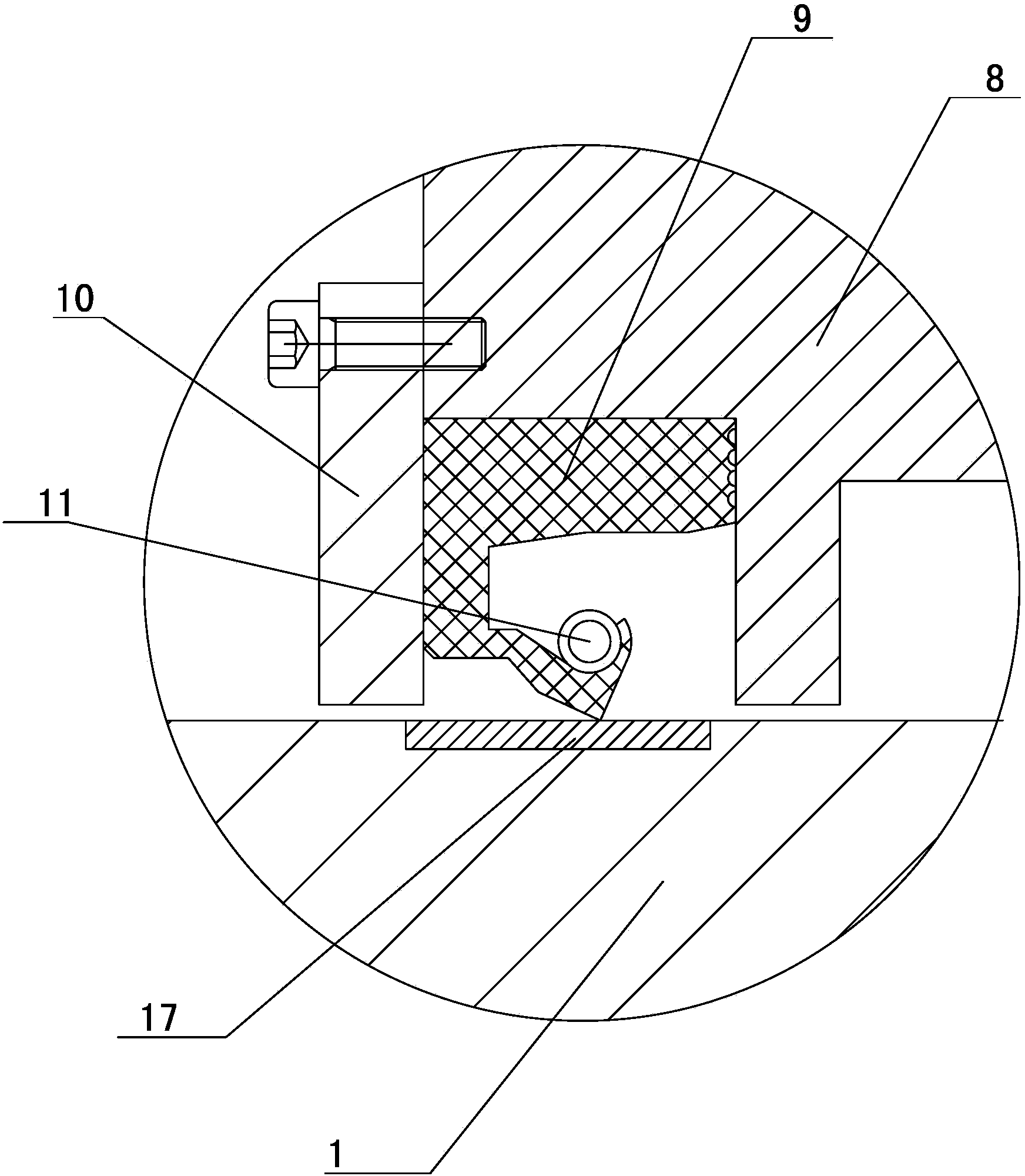

[0025] The first sealing structure, the first oil collecting assembly and the second oil collecting assembly in embodiment 3 are the same as the first sealing structure, the first oil collecting assembly and the second oil collecting assembly in embodiment 2, except that image 3 As shown: the second sealing structure includes a sealing seat 8, a second skeleton sealing ring 9 with a "V"-shaped opening facing the movable cavity of the roller, a second sealing cover plate 10 and an annular wear-resistant ring fixed on the main shaft 1 Steel belt 17; the sealing seat 8 is fixed to the rotor 4, the second sealing cover 10 is fixed to the sealing seat 8, and the second skeleton sealing ring 9 is fixedly installed on the sealing seat 8, the annular wear-resistant steel belt 17 and the second sealing cover In the cavity surrounded by 10, the opening of the second skeleton sealing ring 9 is provided with a second spring fastening ring 11 for ensuring the sealing fit between the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com