Wet type processing device

A technology of wet treatment and liquid treatment, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of increased usage of washing liquid and achieve the effect of reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

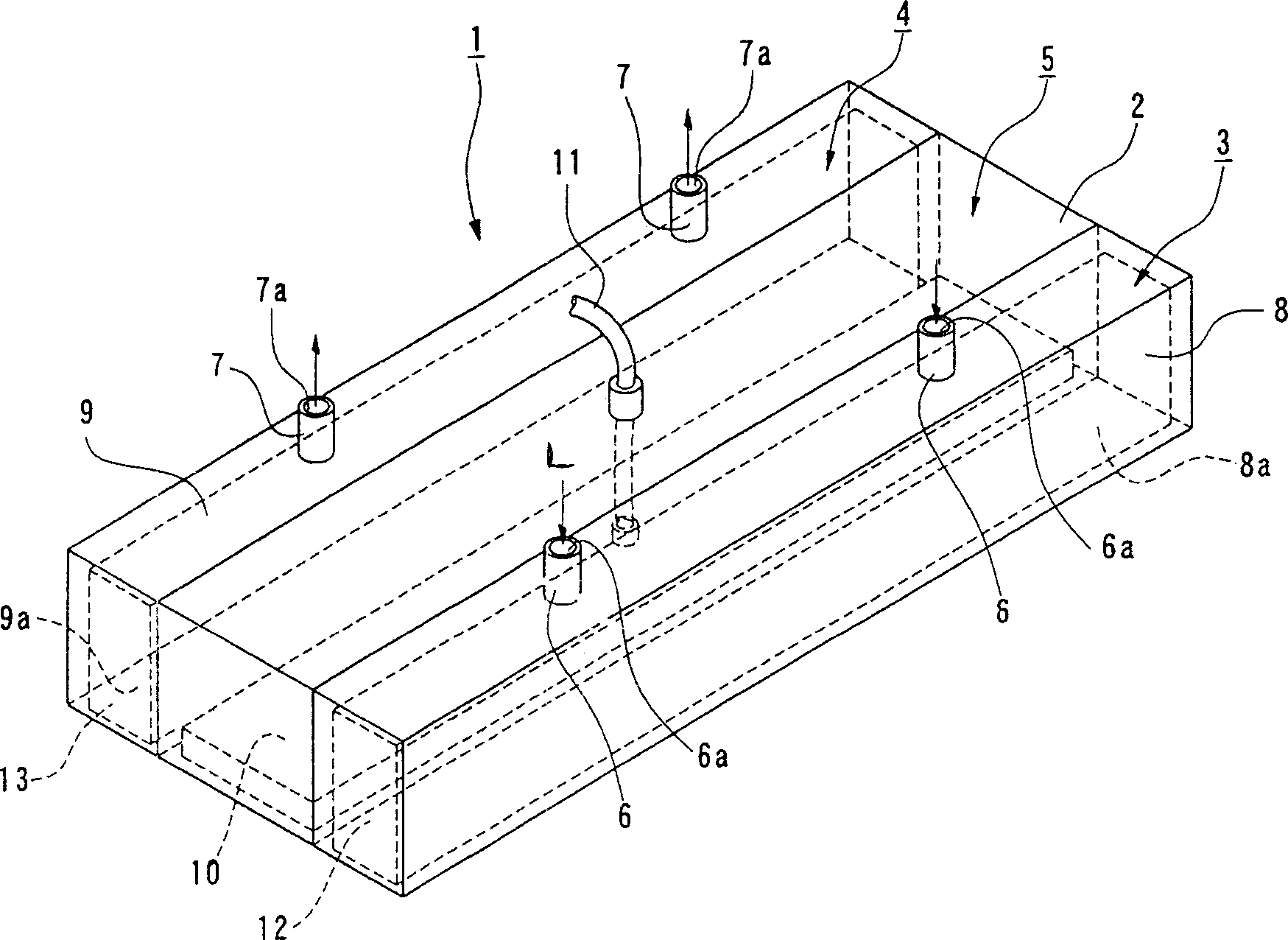

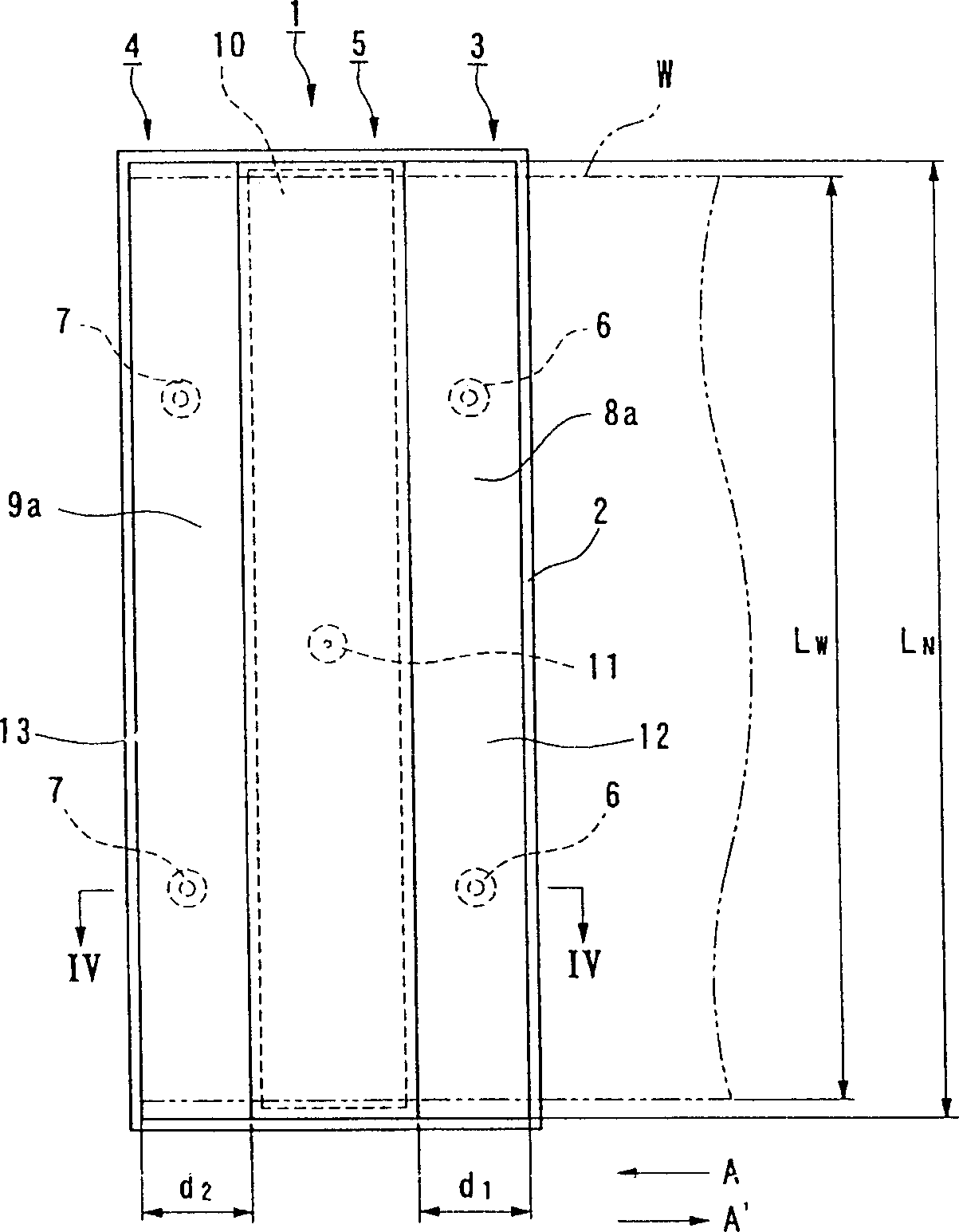

[0044] Below, refer to Figure 1 to Figure 10 The first embodiment of the present invention will be described.

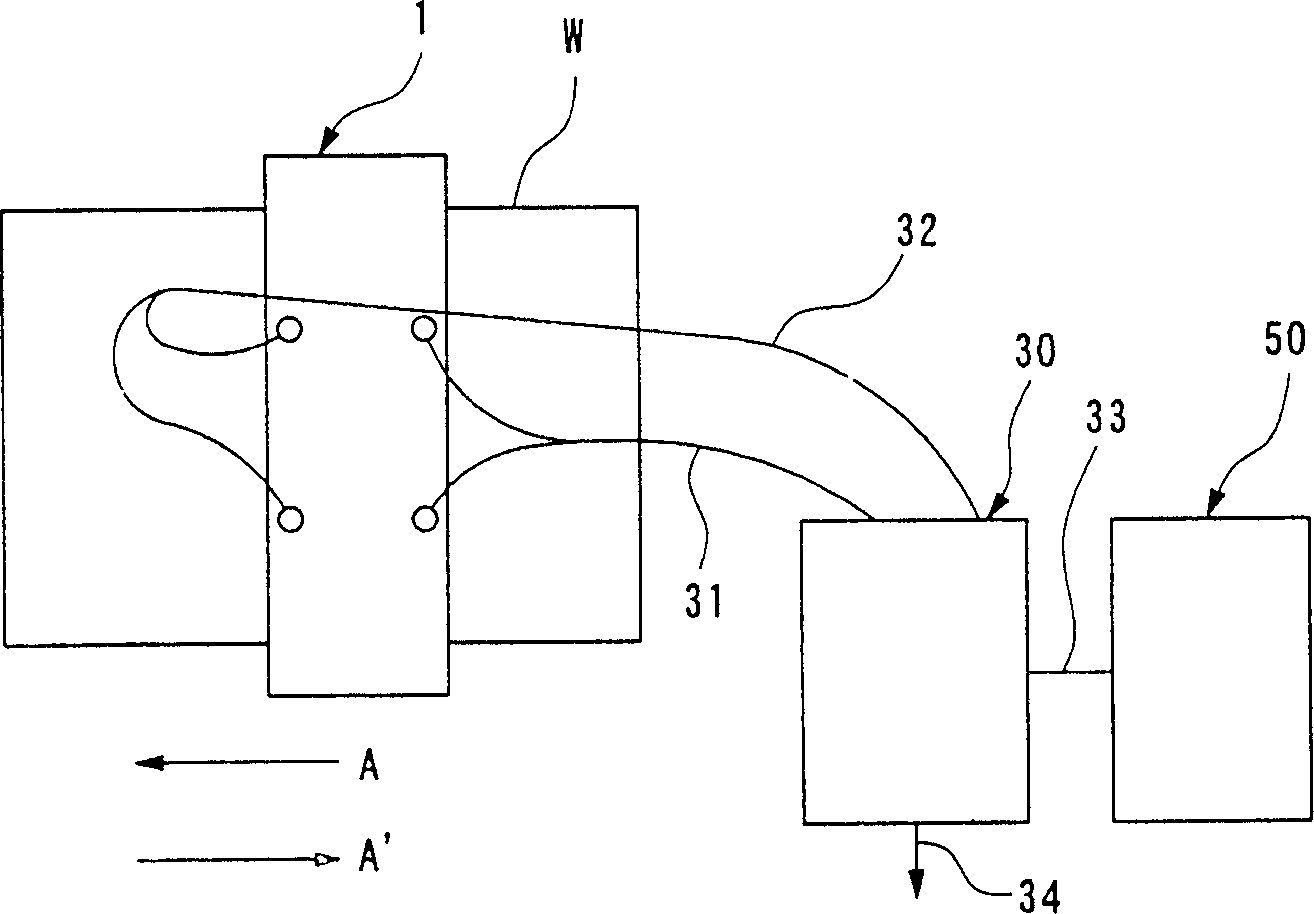

[0045] figure 1 It is a plan view showing the general structure of the cleaning device (wet processing device) of this embodiment. Such as figure 1 As shown, the cleaning apparatus of this embodiment is constituted by the following mechanism, that is, the nozzle 1 for cleaning and the substrate W (hereinafter referred to as the substrate) as the object to be processed are moved to the moving direction A or A'. Mechanism (not shown in the figure) and, washing liquid introduction recovery mechanism 30 and, washing liquid preparation mechanism 50.

[0046] exist figure 1 In the figure, reference numeral 31 is an introduction flow path of the washing liquid introduction and recovery mechanism 30, which is divided into two flow paths at the end and connected to the nozzle 1 for washing. In addition, reference numeral 32 is a recovery flow channel for introducing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com