Heat exchange device capable of being applied to various places

A technology for heat exchange devices and occasions, which is applied in the directions of heat exchanger sealing devices, heat exchanger types, heat exchanger shells, etc., which can solve the problem of general heat energy replacement, failure to meet market demand, and generalization of heat exchange devices and other issues to achieve the effect of increasing the heat energy replacement area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

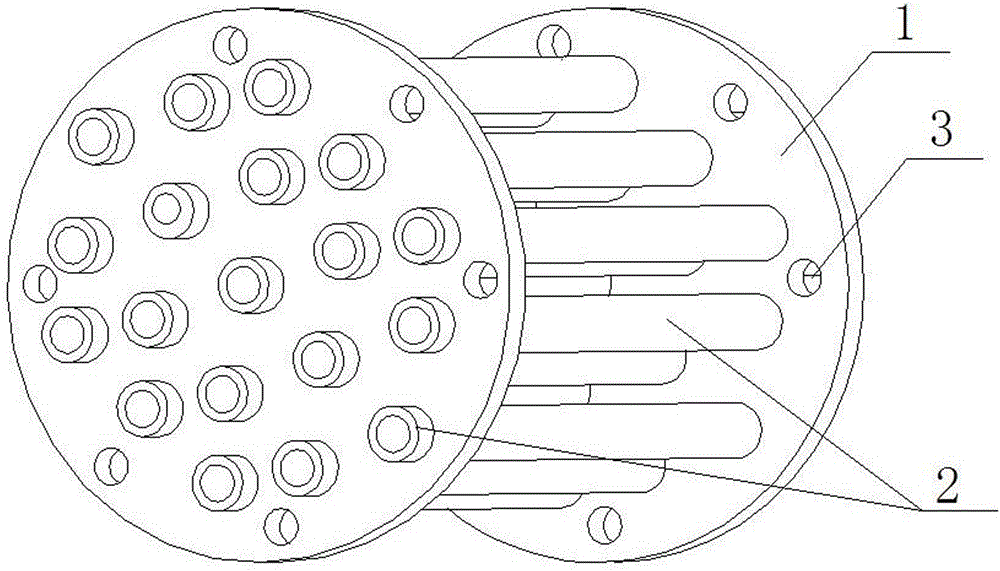

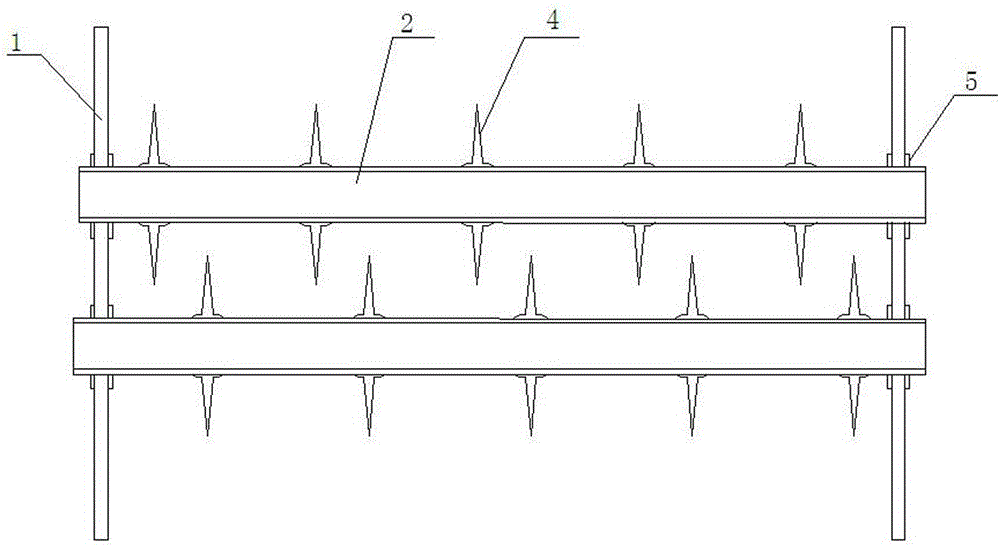

[0019] A heat exchange device that can be applied to various occasions, including a tube sheet 1 and a heat exchange tube 2; it is characterized in that: both ends of the heat exchange tube 2 are connected to the tube sheet 1 and extend to the outside of the tube sheet 1, and the tube The plate 1 is provided with a plurality of spiral through holes 3; the joint between the tube plate 1 and the heat exchange tube 2 is provided with a sealing device 5; the heat exchange tube 2 is provided with a plurality of fins 4, the A plurality of heat exchange tubes 2 are arranged on the tube sheet 1, and the heat exchange tubes 2 are arranged in a staggered manner on the tube sheet 1, and the fins 4 on the heat exchange tubes 2 are directly arranged in a staggered manner.

[0020] The heat exchange tube 2 is made of graphene.

[0021] The two ends of the heat exchange tube 2 are provided with protrusions at the junction with the tube sheet 1 , and the interior of the tube sheet 1 is provid...

Embodiment 2

[0024] The working principle of the present invention:

[0025] In the present invention, by staggering a plurality of heat exchange tubes 2 on the tube sheet 1 and arranging the fins 4 on the heat exchange tubes 2 in a staggered manner, the contact area between the tube wall and the external heat exchange material is effectively increased, and at the same time It also increases the area of the material inside the heat exchange tube 2 to transfer heat energy to the outside; while the connection between the heat exchange tube 2 and the tube sheet 1 is connected by a pattern of protrusions and grooves, which strengthens the connection and increases Certain sealing performance, and the sealing device 5 is provided inside and outside the connection, which further strengthens the sealing performance between the heat exchange tube 2 and the tube sheet 1, and prevents the internal heat exchange material from running out of the connection; the tube sheet 1 The screw through hole 3 o...

Embodiment 3

[0027] In the present invention, both ends of the heat exchange tube 2 can be connected to the tube sheet 1, and the heat exchange tube 2 is cylindrical, and is suitable for flue gas heat exchange (economizer) inside a boiler or plumbing heat exchange and other occasions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com