Protective sleeve fabricated with hybrid yarn, hybrid yarn, and methods of construction thereof

一种混合纱、套管的技术,应用在带有双股绞合的/四股绞合的电缆、纱、纺织品和造纸等方向,能够解决构造工艺昂贵、传导性成分传导性连接无效、影响套管性能等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

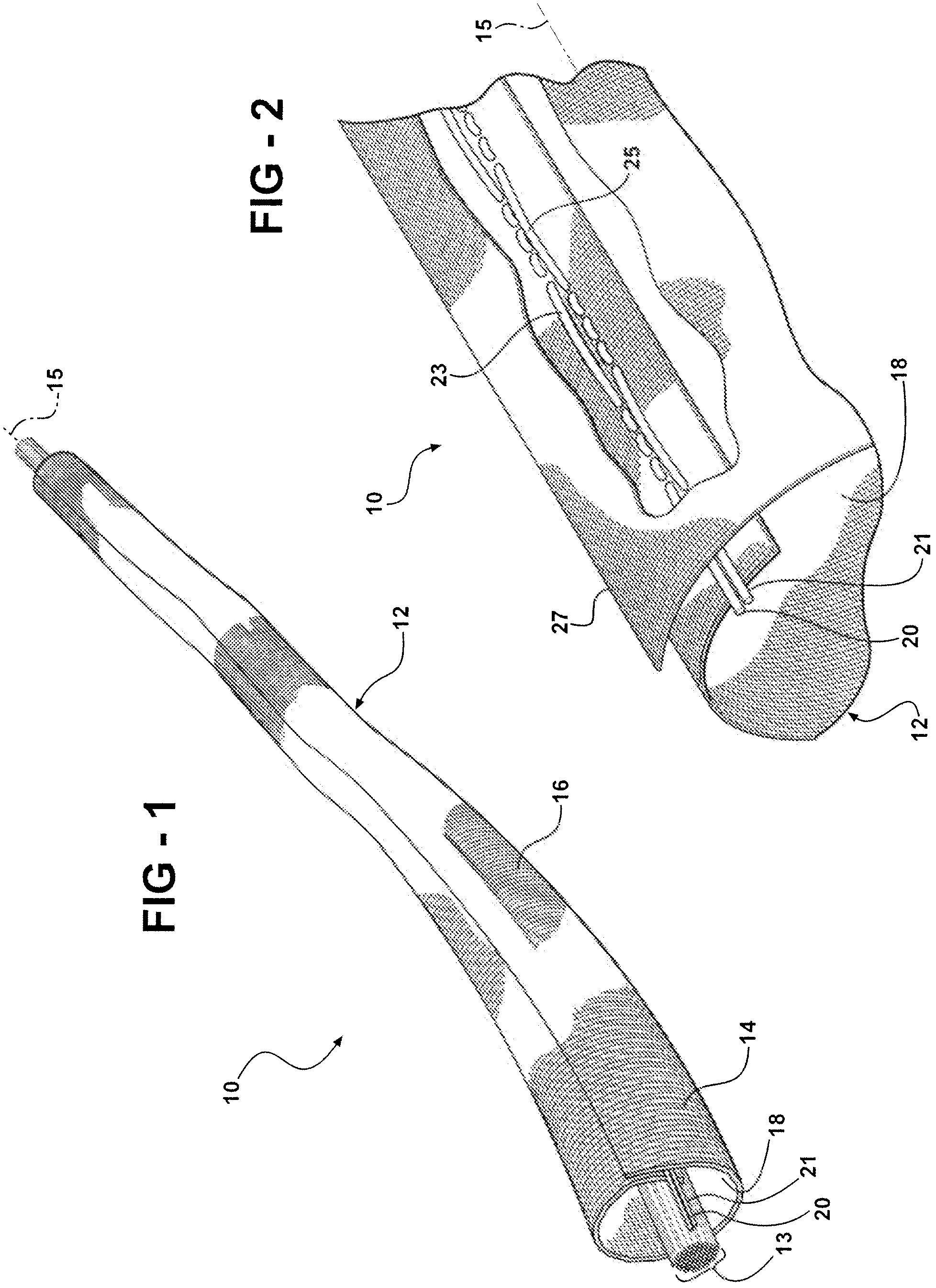

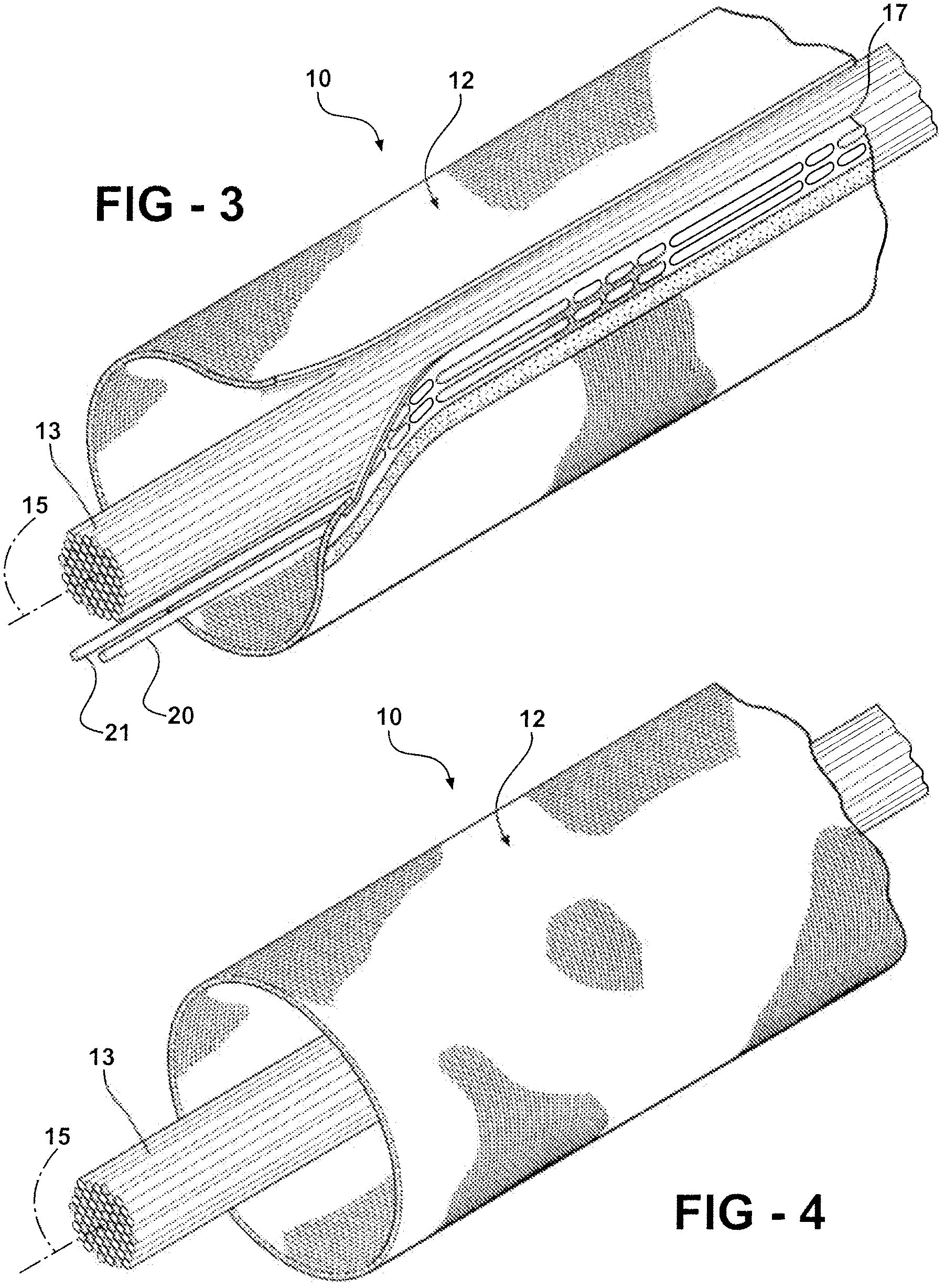

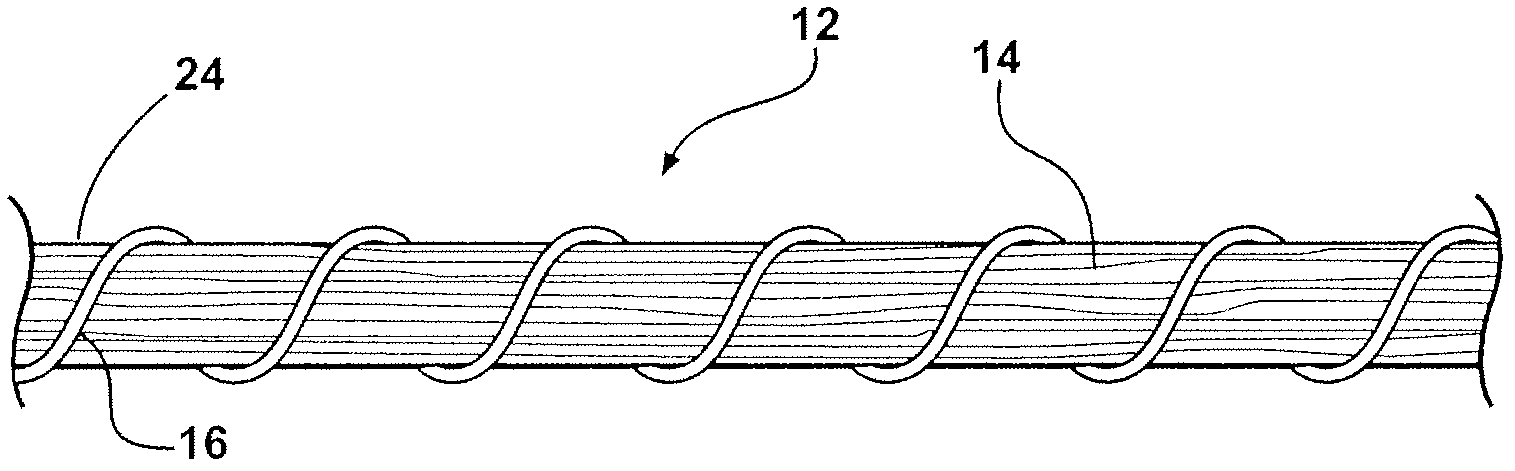

[0030] Referring more particularly to the drawings, FIG. 1 shows a sleeve 10 constructed in accordance with the present invention constructed from yarns comprising at least some blended yarns or filaments, hereinafter simply referred to as blended yarn elements 12 . The term filament here includes monofilaments and / or multifilaments, with specific reference to the type of filament. Non-conductive monofilament and / or non-conductive multi-filament elements (hereinafter referred to as non-conductive element 14 unless otherwise specified) twisted and / or wound micron-scale continuous conductive wire filaments (hereinafter referred to as wire filaments) Filament 16) forms hybrid yarn element 12 (Figs. 5-16). For example, the diameter of each wire filament 16 is about 20-100 μm, and the wire filament provides electromagnetic interference (EMI), radio frequency interference (RFI) and / or protection from at least one of electrostatic discharge (ESD). Once enclosed, the generally seale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com