Belt deviation intelligent correcting system and correcting method for belt conveyor

A technology of belt conveyors and belts, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve problems such as inability to intelligently adjust belt deviation at any time, damage to the tail wheel, and belt wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

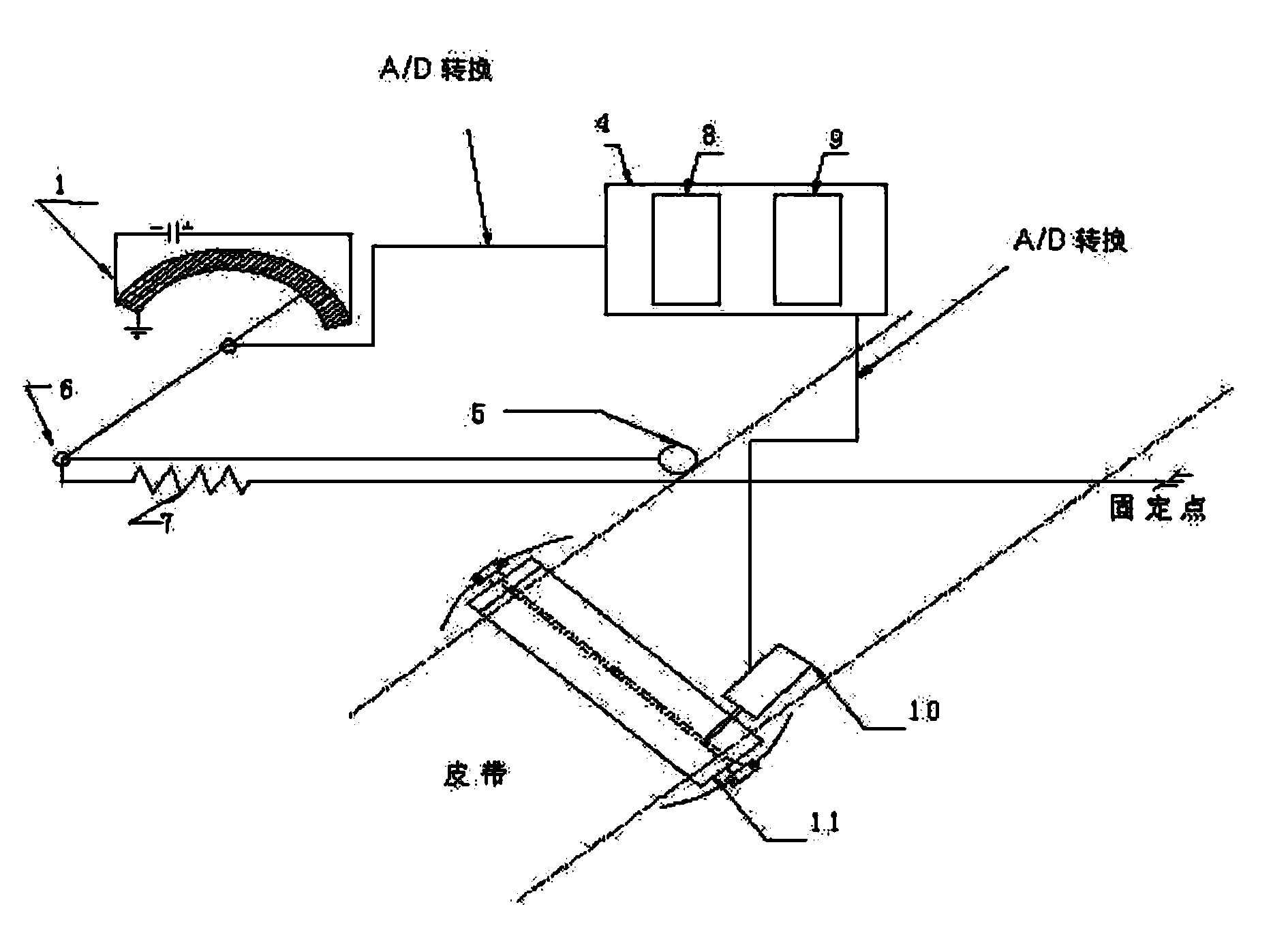

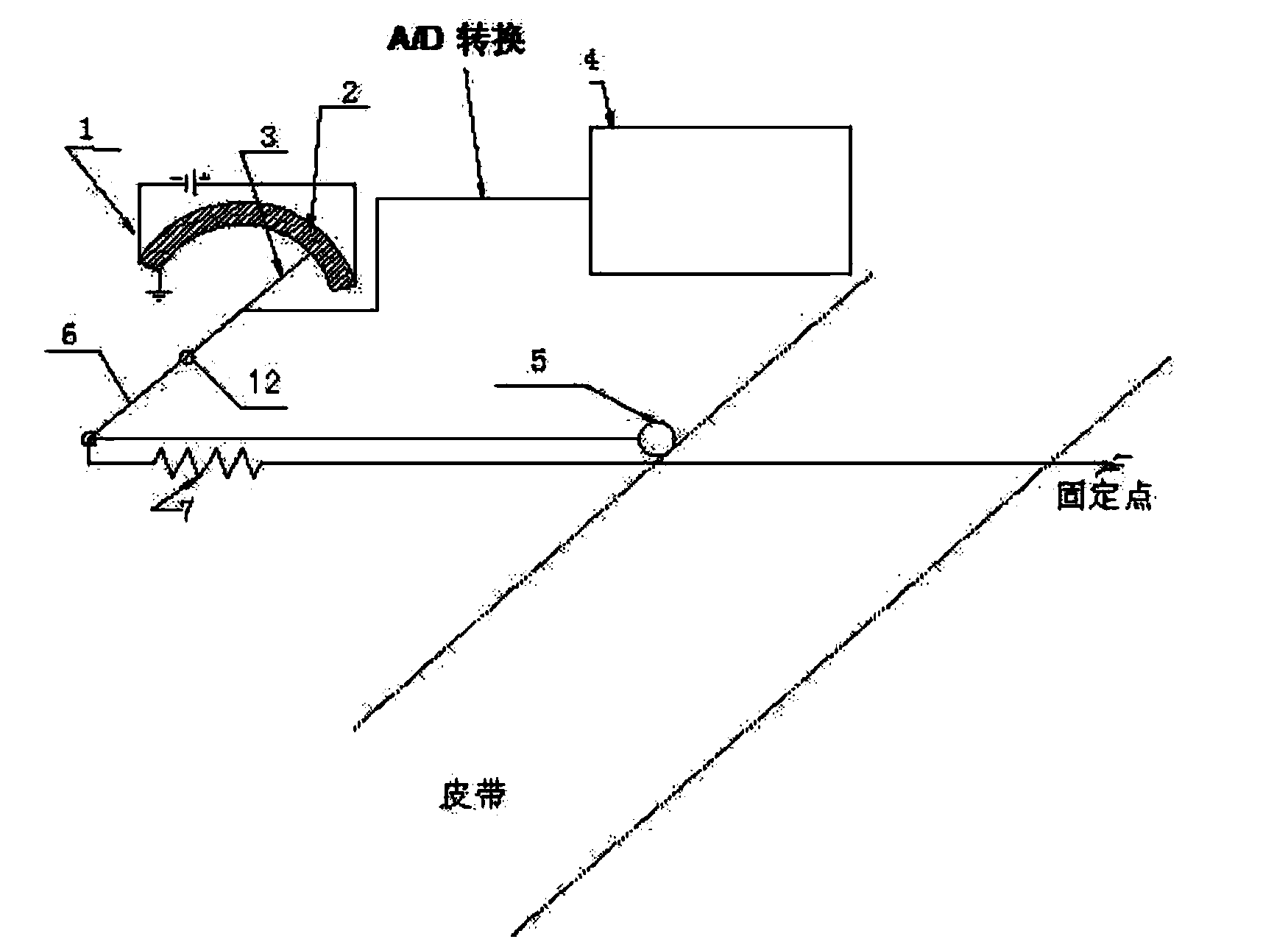

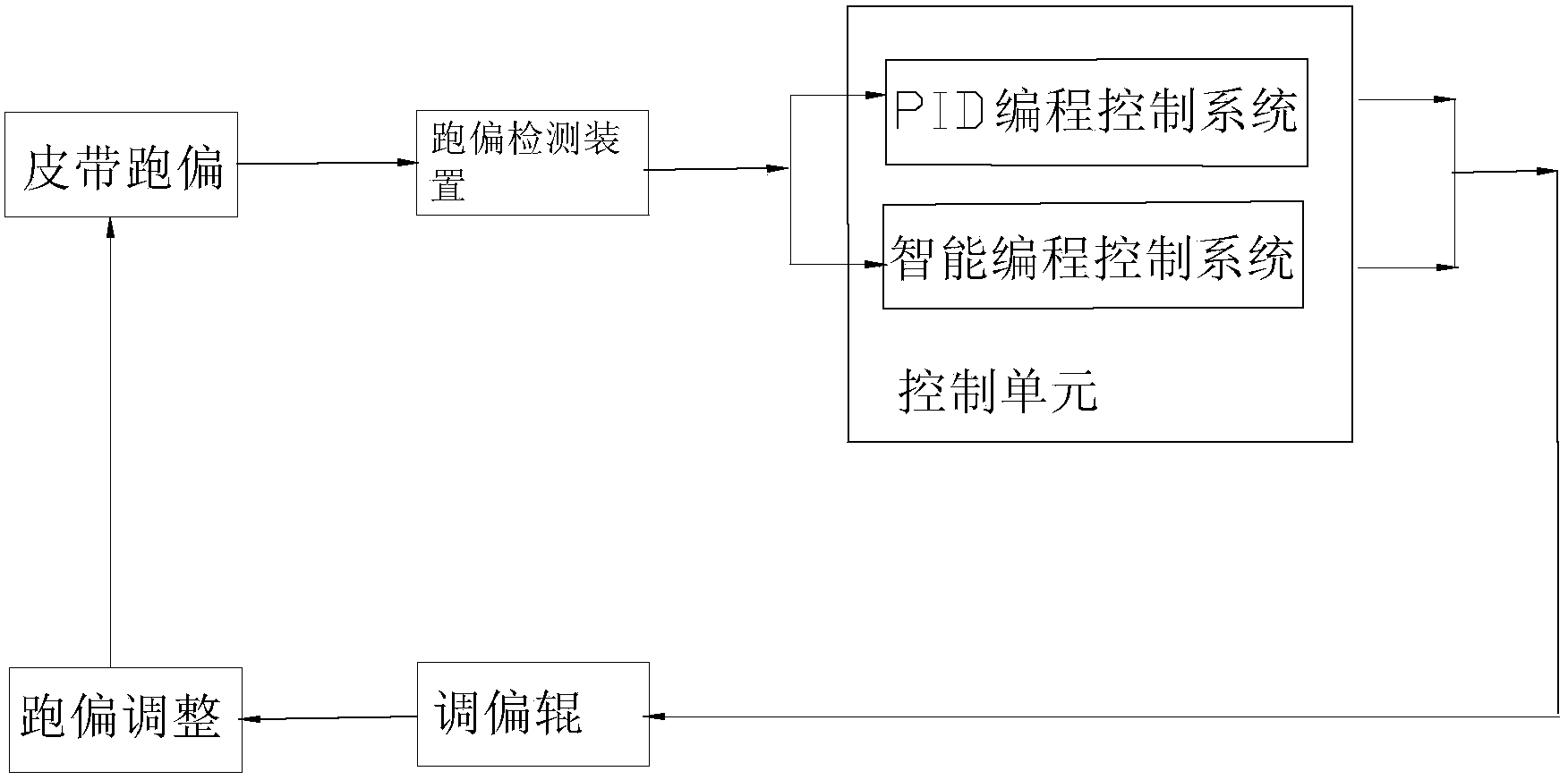

[0030] Such as figure 1 As shown, the belt deviation intelligent correction system of the belt conveyor, according to the installation situation of the belt conveyor on site, the length of the belt and the previous operation conditions, installs the belt deviation detection device at the position prone to deviation (at the head, middle and tail of the belt) ; The output signal of the belt deviation detection device is connected to the control unit 4 through A / D conversion, and the output of the control unit 4 is connected to the deviation adjustment screw driver 10 to drive the deviation adjustment roller 11 after D / A conversion.

[0031] The belt deviation detection device comprises a potentiometer type displacement sensor 1 composed of a sliding piece 3 and a winding 2 arranged on a belt shelf, the middle part of the sliding piece 3 has a fixed shaft 12, and one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com