Lining machining method

A processing method and bushing technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as poor environmental performance, impact on the service life of bushings, and large loads, and achieve good environmental performance and improved working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

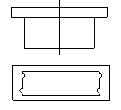

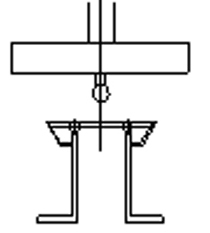

[0025] A processing method of the bushing in the present invention, the following steps are carried out on the copper-based bimetallic steel strip: 1) blanking; 2) punching the buckle; 3) punching U-shaped; 4) full circle; and then completing the lining by extrusion The surface roughness and wall thickness required by sleeve 1 are achieved through extrusion, that is, three processes of finishing the circle, grinding the outer circle, and boring the inner circle are completed by extrusion to complete the processing of the bush 1. The power required for extrusion is air pressure or hydraulic pressure, and the pressure and moving speed required for extrusion can be continuously adjusted. The fixed die during extrusion is a die structure 3, and the other corresponding extruding movable die is a punch structure 2, and of course the fixed die can also be a punch structure. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com