A method of in-situ self-assembly toughening modified bismaleimide resin

A technology of bismaleimide and toughening modification, which is applied in the field of thermosetting resins, can solve the problems of lowering the glass transition temperature and modulus of polymers, high viscosity of modified resin systems, and poor processing technology to achieve bending Increased strength, improved tensile strength, and high universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

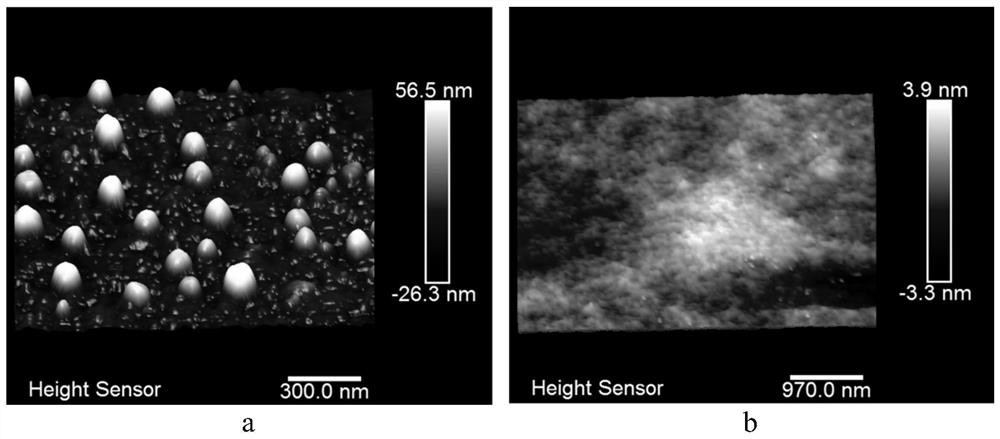

Image

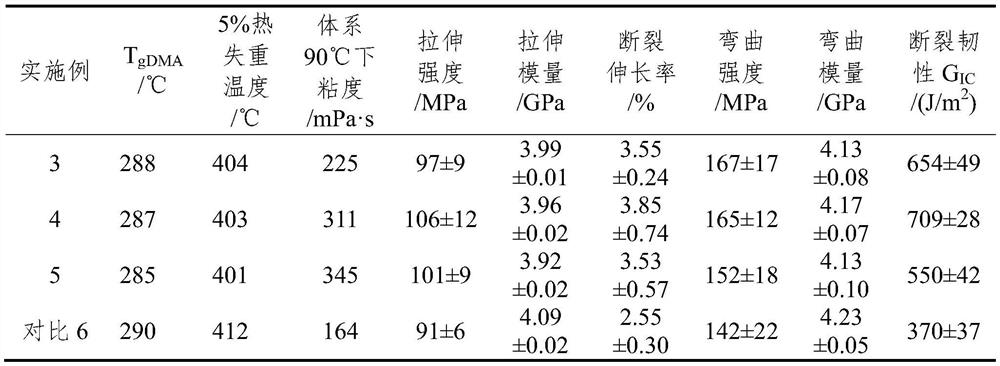

Examples

Embodiment 1

[0016] Bismaleimide is preferably N,N'-(4,4'-methylenediphenyl) bismaleimide, diallyl phenyl compound is preferably diallyl bisphenol A, reactive diluent The preferred N-phenyl maleimide of agent, the preferred n-dodecyl maleimide of active flexible chain additive;

[0017] Add 185g of diallyl bisphenol A into a three-necked flask, raise the temperature to 130°C, and add 358g of N,N'-(4,4'-methylenediphenyl)bismaleimide while stirring, Insulate and dissolve into a homogeneous phase, then add 38g of N-phenylmaleimide, and keep at 120°C for 30min to obtain bismaleimide resin I;

[0018] Add 29g of n-dodecylmaleimide into the above-mentioned bismaleimide resin I, stir and mix evenly at 90°C to obtain modified bismaleimide resin I-1.

Embodiment 2

[0020] Bismaleimide is preferably N,N'-(4,4'-methylenediphenyl) bismaleimide, diallyl phenyl compound is preferably diallyl bisphenol A, reactive diluent The preferred o-allyl phenol of the agent, the preferred n-octylmaleimide of the active flexible chain additive;

[0021] Add 136g of diallyl bisphenol A into the flask, raise the temperature to 130°C, and add 330g of N,N'-(4,4'-methylenediphenyl)bismaleimide while stirring, Heat preservation and dissolve into a homogeneous phase, then add 67g of o-allylphenol, and heat at 120°C for 30min to obtain bismaleimide resin II;

[0022] 16g of n-octylmaleimide was added to the above-mentioned bismaleimide resin II, stirred and mixed uniformly at 90°C to obtain modified bismaleimide resin II-1.

Embodiment 3

[0024] Bismaleimide is preferably N,N'-(4,4'-methylenediphenyl)bismaleimide and N,N'-m-phenylene bismaleimide, according to the mass ratio 80:20 combination, the diallyl phenyl compound is preferably diallyl bisphenol A, the reactive diluent is preferably o-allyl phenol, and the active flexible chain additive is preferably n-octylamine;

[0025] Add 215g of diallyl bisphenol A into the flask, raise the temperature to 130°C, add 64g of N,N'-m-phenylene bismaleimide bismaleimide under stirring, keep warm until it dissolves into a homogeneous phase, then add 256g N,N'-(4,4'-methylenediphenyl)bismaleimide, keep warm to dissolve into a homogeneous phase, then add 50g o-allylphenol, keep warm at 120°C for 30min, Obtain bismaleimide resin III;

[0026] Add 5.8g of n-octylamine to the above-mentioned bismaleimide resin III, stir and mix evenly at 90°C to obtain modified bismaleimide resin III-1, vacuumize to remove air bubbles, and cure as usual Process pouring and curing, you can o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com